Preparing method for antler polypeptide or tortoise plastron polypeptide

A technology of tortoise shell and antler, which is applied in the field of antler polypeptide or tortoise shell polypeptide, can solve the problems of poor processing performance and difficult absorption, and achieve the effects of improved processing performance, simple production equipment, and easy digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

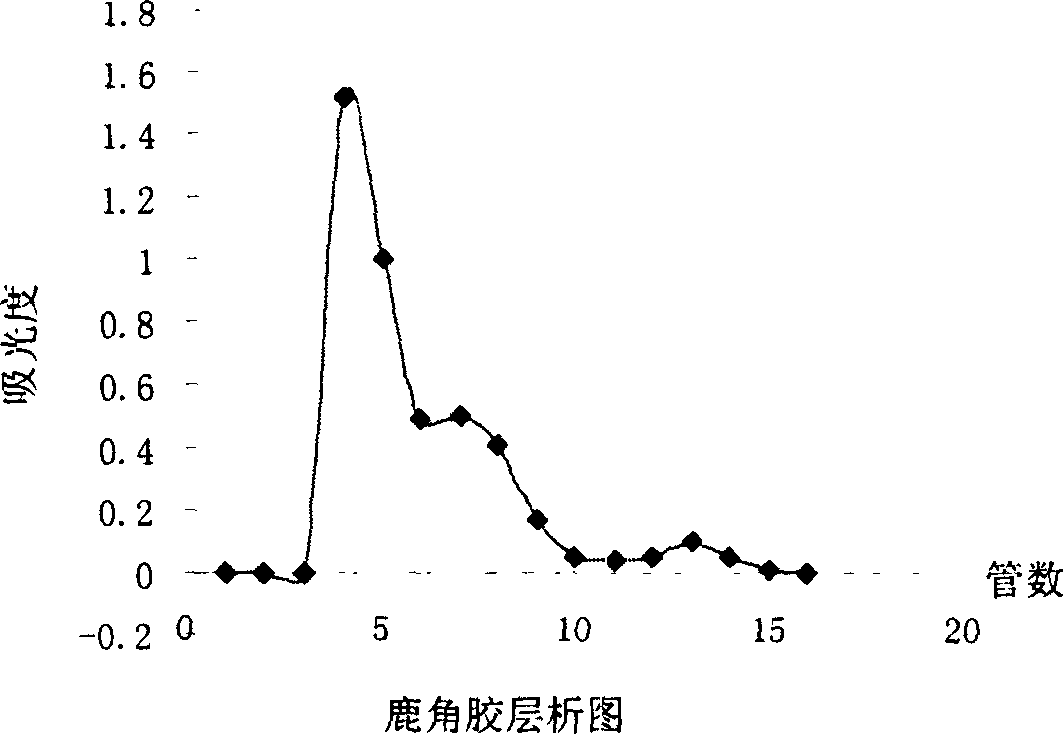

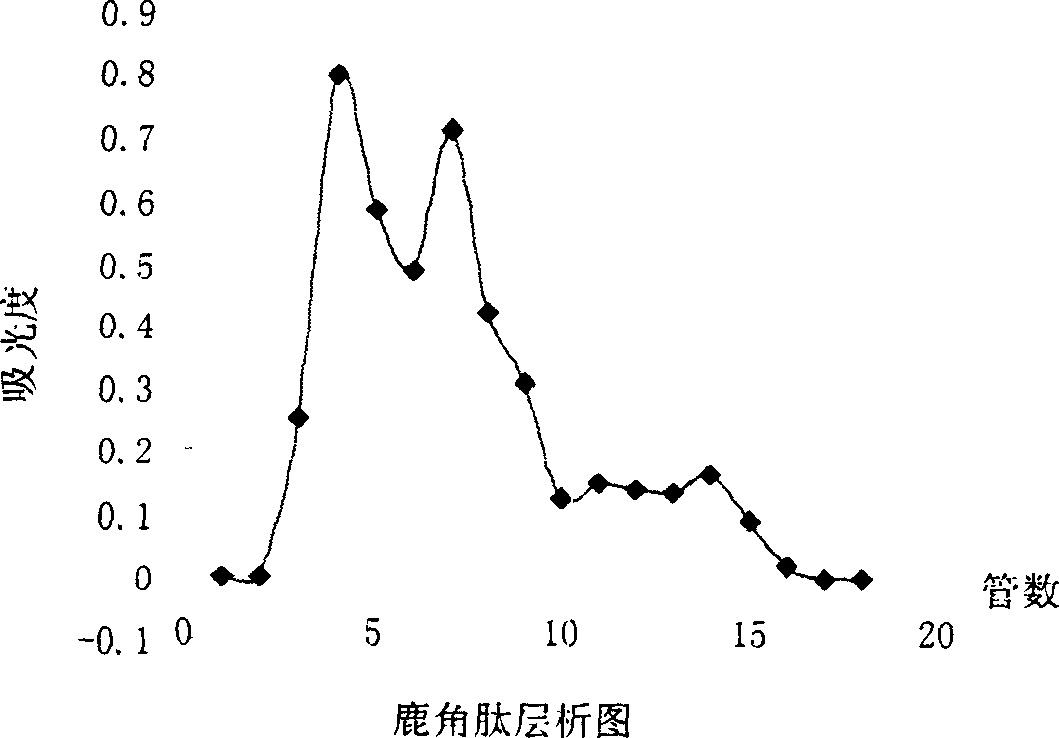

[0024] Embodiment 1: use distilled water to dissolve deer horn gum into the deer horn gum aqueous solution that mass percent concentration is 10%, boil 5 minutes, when its temperature is cooled to 45~58 DEG C, be placed in the constant temperature water bath of 55 DEG C; After temperature balance , first adjust its pH value to 7.8 with a calcium hydroxide solution with a concentration of 25% by mass percentage; then add trypsin to carry out enzymolysis according to 6% of the mass of the antler gum, the enzymolysis temperature is maintained at 55°C, and the enzymolysis time is 8 hours , to obtain the first enzymatic hydrolysis solution, and boil the first enzymatic hydrolysis solution for 5 minutes to inactivate the activity of trypsin. Add neutral protease labeled A.S1398 according to 6% of the mass of deer horn glue for enzymolysis, the enzymolysis temperature is maintained at 55°C, and the enzymolysis time is 3 hours to obtain the second enzymolysis solution, and the second e...

Embodiment 2

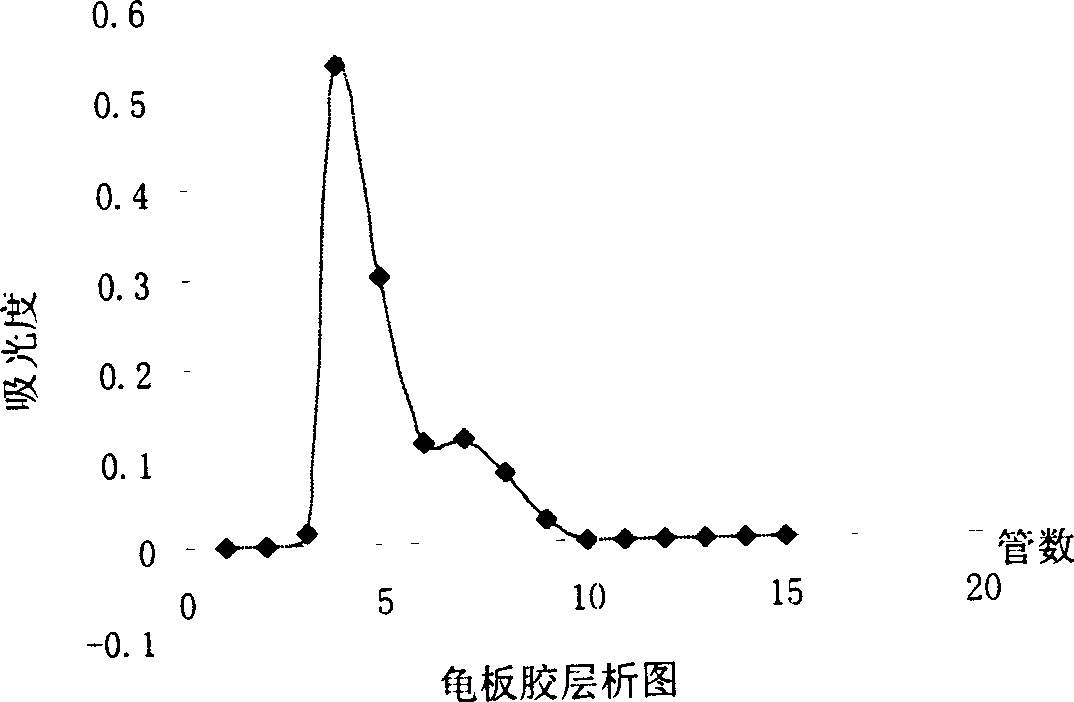

[0025] Example 2: Dissolve tortoise shell glue with distilled water into an aqueous solution of tortoise shell glue with a mass percentage concentration of 8%, boil for 3 minutes, and place it in a constant temperature water bath at 55°C when the temperature is cooled to 45-58°C; after temperature balance , first adjust its pH value to 8 with a calcium hydroxide solution with a concentration of 30% by mass percentage; then add trypsin to carry out enzymolysis according to 5% of the mass of tortoise shell gum, the enzymolysis temperature is maintained at 55 ° C, and the enzymolysis time is 6 hours , to obtain the first enzymolysis solution, and boil the first enzymolysis solution for 3 minutes to inactivate the activity of trypsin, and when the temperature drops to 45°C-58°C, put it back in a constant temperature water bath at 55°C; According to 5% of the mass of tortoise shell gum, add neutral protease labeled A.S1398 for enzymolysis, the enzymolysis temperature is maintained a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com