Rapid-speed metal piping, bar and wire stock on-line defect detecting method and detector thereof

A flaw detection device and metal tube technology, which can be used in measurement devices, analysis materials, material magnetic variables, etc., can solve problems such as toxicity, low excitation frequency, and corrosion, and achieve the effects of eliminating complex circuit structures, eliminating noise, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

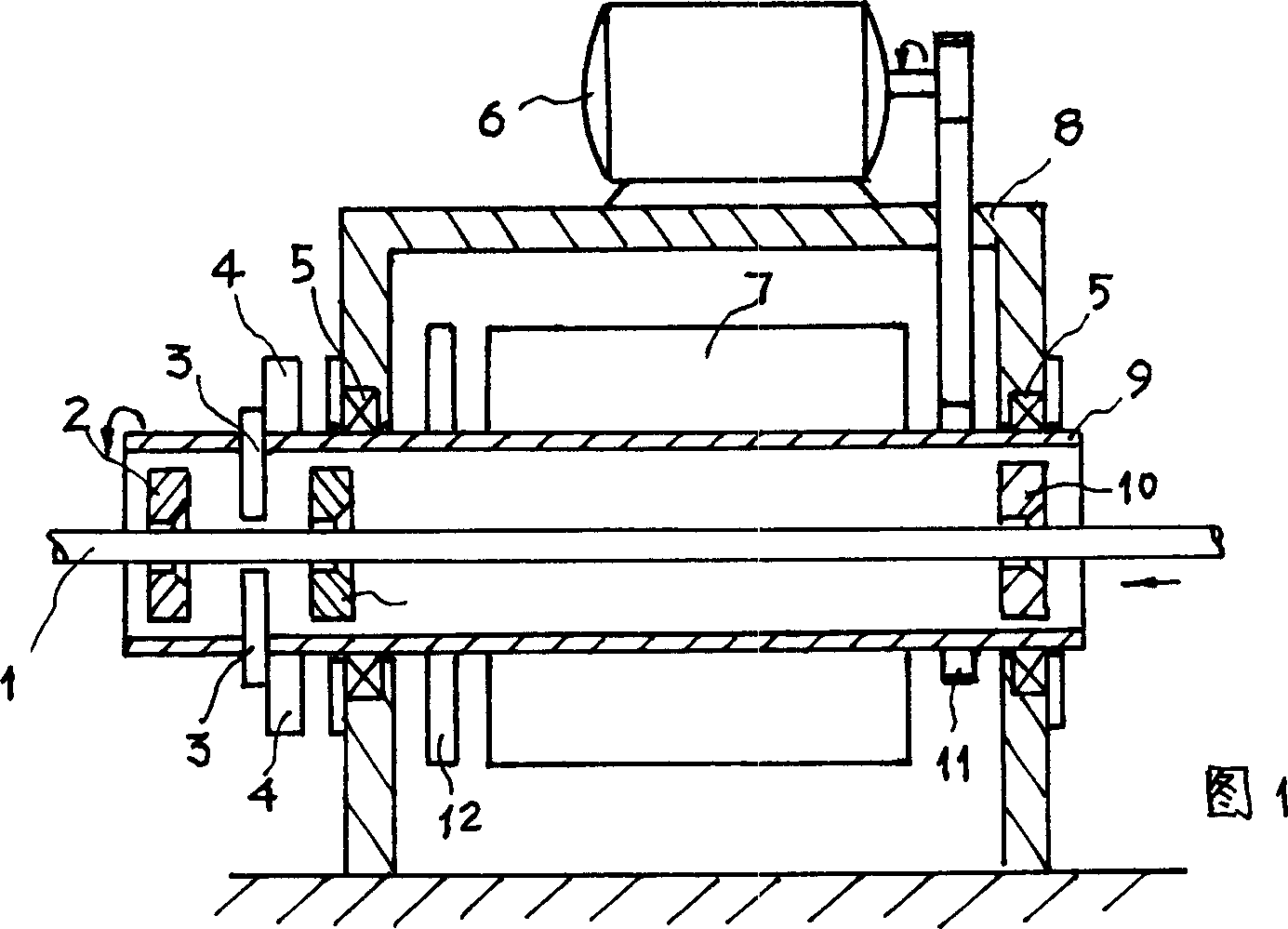

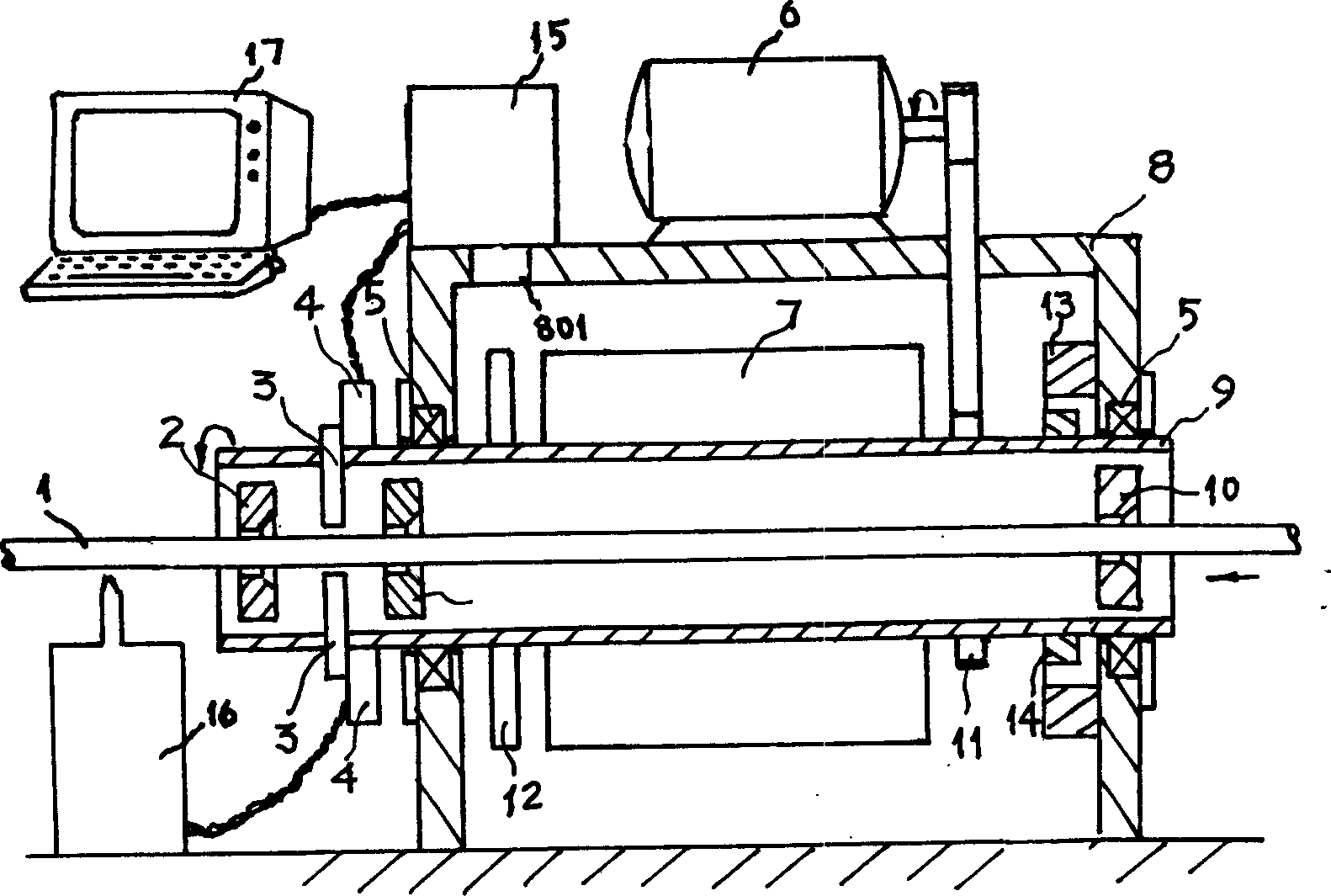

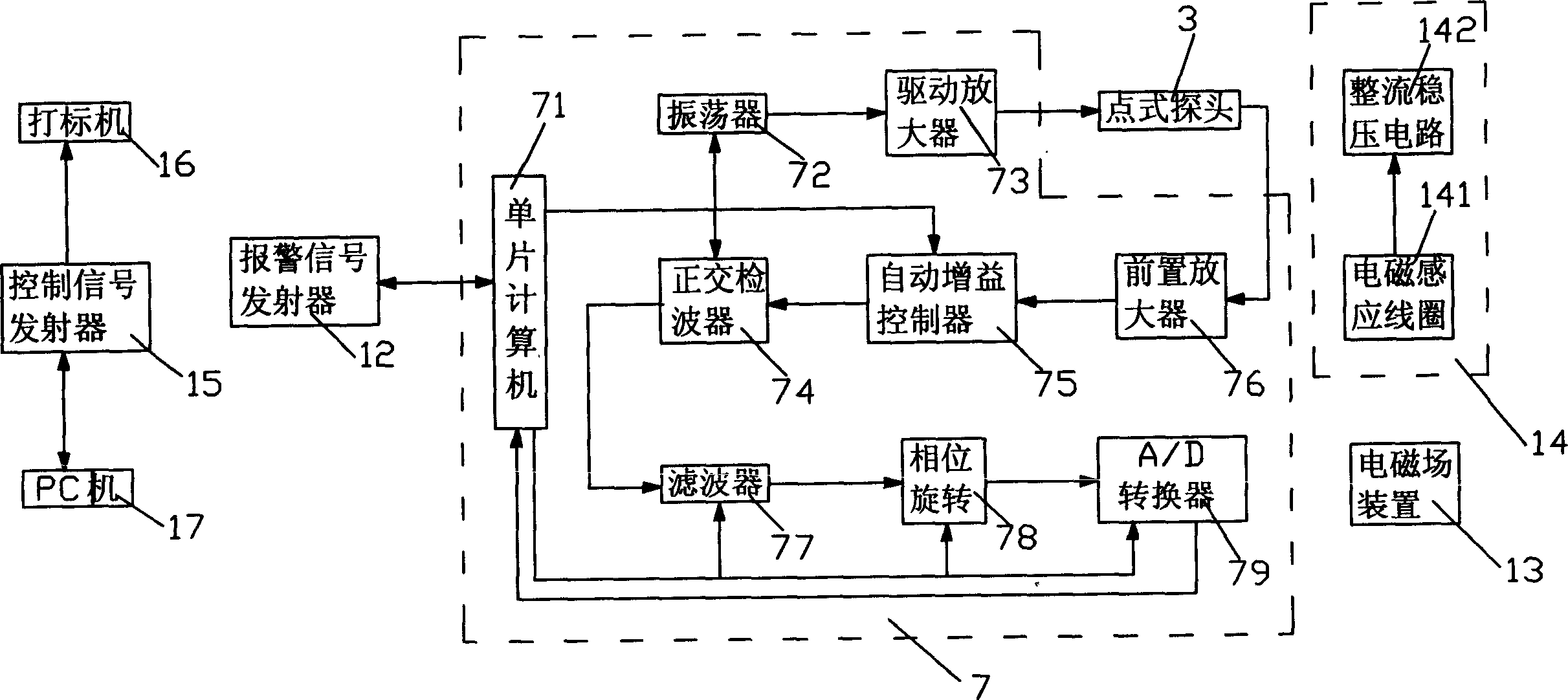

[0018] Please refer to FIG. 1 for the structure of an embodiment of the high-speed metal tube, rod, and wire online flaw detection device of the present invention. The on-line flaw detection device has a frame 8 fixed on the ground, the frame 8 is hollow inside, and a pair of bearings 5 are respectively installed on both sides of the waist, and the hollow rotating mechanism main shaft 9 is fixed through the two pairs of bearings 5 . The front end inside the main shaft 9 is provided with a pair of centering sleeves 2, and the rear end is provided with an introduction sleeve 10; metal pipes, rods, and wires 1 moving linearly at high speed enter the interior of the main shaft 9 from the center hole of the introduction sleeve 10, and are centered from the two centering sleeves. The central hole of cover 2 passes through and leads to the outside of main shaft 9 . The two centering sleeves 2 and the guide sleeve 10 keep the section of the metal pipe, rod, and wire 1 inside the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com