Decoloring method for paper-making middle section water

A mid-section water and water body technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as no technical solution proposed, achieve good disinfection effect, ingenious design ideas, preparation handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

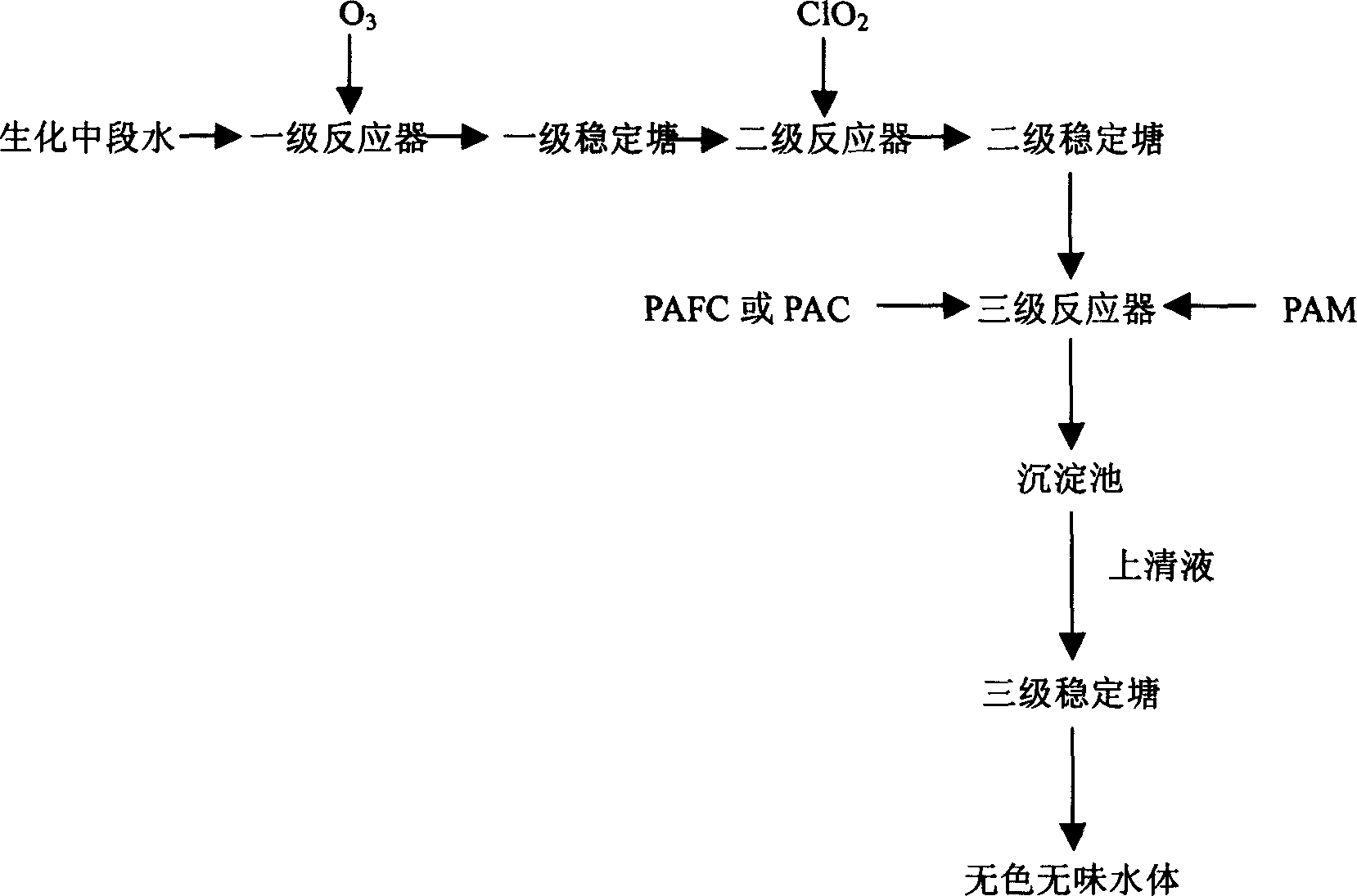

Embodiment 1

[0048] Introduce 1000 tons of biochemically treated mid-section water (COD is 330mg / L, chromaticity 64 times) into the first-level folded plate reaction tank, and add 15kg of O in the tank. 3 , reacted for 2 hours, the water decolorized by the first stage entered the first stage stabilization pond, left standing for 48 hours, the effluent chromaticity was 32 times, entered the second stage folded plate reaction tank, and added 5kg of ClO to the second stage folded plate reaction tank 2 , reacted for 1.5 hours, then entered the secondary stabilization pond, left standing for 48 hours, the effluent color was 16 times, entered the tertiary reactor, and added 100kg PAFC (PAFC-B 1 type, Changzhou Zhenbang Chemical Manufacturing Co., Ltd.), after 15 minutes, add 1kg of PAM (molecular weight 18 million, anionic type, Yixing Angel Synthetic Chemical Co., Ltd.), react for 30 minutes, enter the sedimentation tank, the water chromaticity is 8:00 , enter the tertiary stabilization pond, s...

Embodiment 2

[0050] Introduce 1000 tons of biochemically treated mid-section water (COD is 350mg / L, chromaticity 64 times) into a first-level folded plate reaction tank, and add 20kg of O in the tank. 3 , reacted for 1 hour, the water decolorized by the first stage entered the first stage stabilization pond, left standing for 50 hours, the effluent chromaticity was 32 times, entered the second stage folded plate reaction tank, and added 10kg of ClO to the second stage folded plate reaction tank. 2 , react for 1 hour, then enter the secondary stable pond, stand for 48 hours, the effluent color is 16 times, enter the third-level reactor, add 200kg PAFC (PAFC-B 2 type, Changzhou Zhenbang Chemical Manufacturing Co., Ltd.), after 20 minutes, add 2kg of PAM (molecular weight 15 million, anionic type, Yixing Angel Synthetic Chemical Co., Ltd.), react for 22 minutes, enter the sedimentation tank, the water chromaticity is 8:00 , enter the tertiary stabilization pond, stay for 18 hours, and get a c...

Embodiment 3

[0052] Introduce 1000 tons of biochemically treated mid-section water (COD is 310mg / L, chromaticity 64 times) into a first-level folded plate reaction tank, and add 19kg of O in the tank. 3 , reacted for 1 hour, the decolorized water entered the first-level stabilization pond, left standing for 36 hours, the effluent color was 32 times, entered the second-level folded plate reaction tank, and added 7kg of ClO to the second-level folded plate reaction tank. 2 , reacted for 2 hours, then entered the secondary stabilization pond, left standing for 55 hours, the effluent color was 16 times, entered the tertiary reactor, added 160kgPAC (first-class product, Changzhou Zhenbang Chemical Manufacturing Co., Ltd.), 16 minutes later, Add 1.5kg of PAM (molecular weight 18 million, anionic type, Gongyi Lanxing Water Purification Material Factory), react for 22 minutes, enter the sedimentation tank, the water chromaticity is 8, enter the tertiary stabilization pond, stay for 18 hours, that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com