Pure water unloading overflow valve

An overflow valve and pure water technology, applied in fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of unsuitable water medium, strong corrosion of water medium, unsuitable water medium, etc., to achieve shortening Opening and reset time, improved response speed, short stroke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

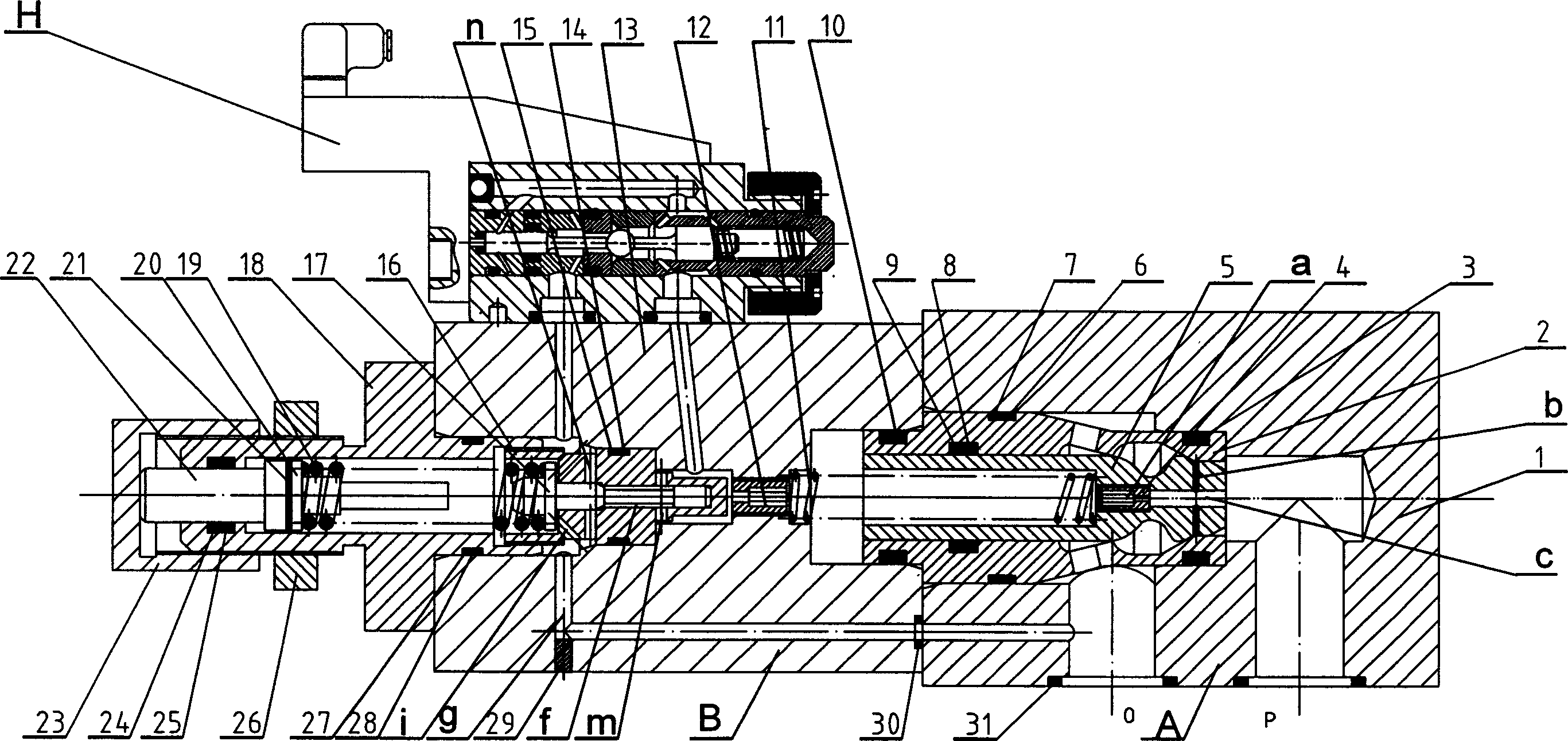

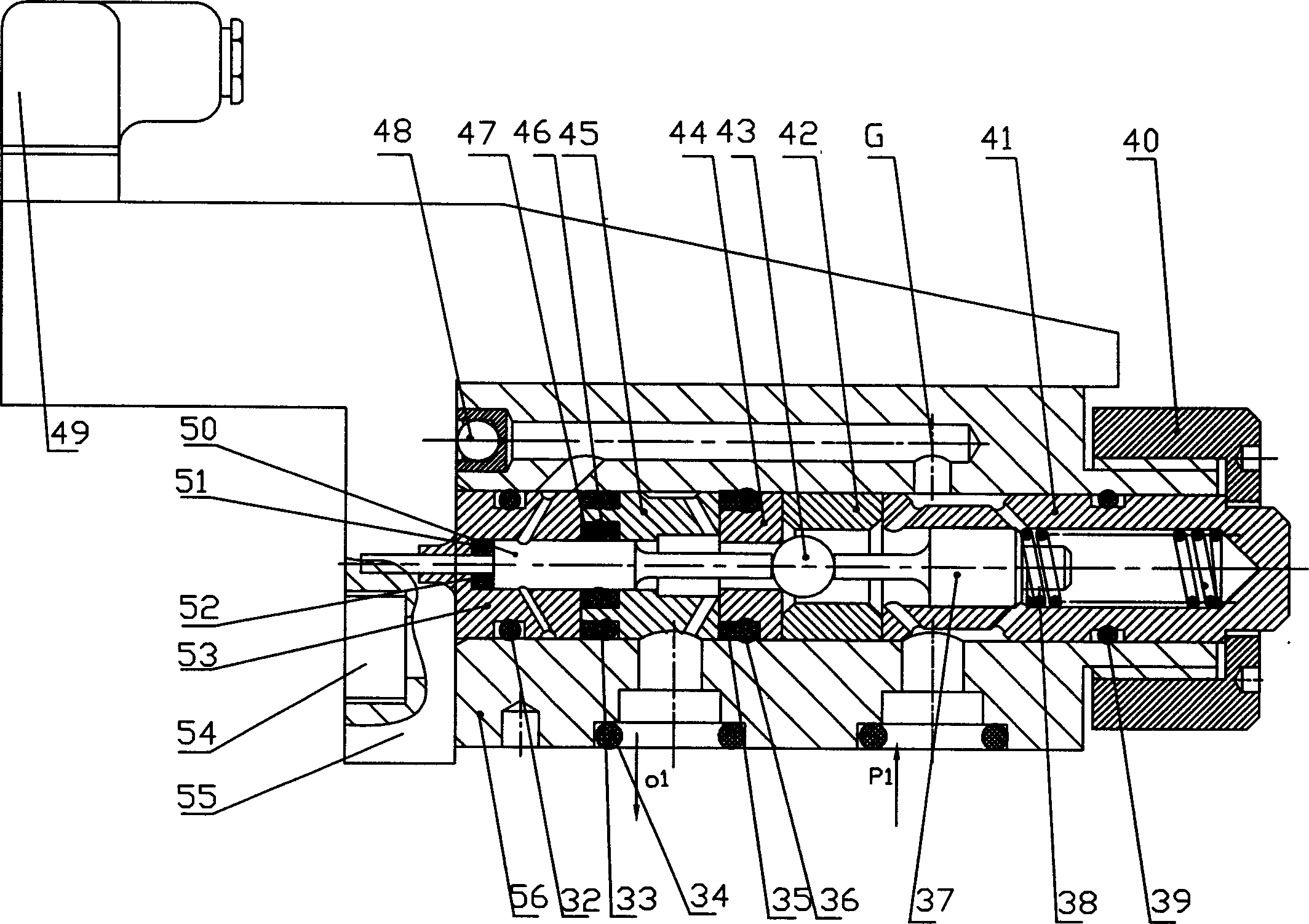

[0027] The pure water unloading overflow valve is composed of coaxial main valve A, pilot valve B, and pure water electromagnetic switching valve H, of which:

[0028]1) Main valve A: including the main valve body 1, the main valve sleeve 2 installed in the main valve body 1 hole, the main valve core 5 is installed in the main valve sleeve 2, and the main valve core 5 is installed in the small through hole Liquid resistance 4, the main valve spring 11 is installed in the large through hole of the main valve core 5, when the main valve core 5 is opened, two series-connected variable throttle ports are formed between the main valve core 5 and the main valve sleeve 2, the main valve There are water inlet P and water return port O on the body 1, the liquid flow of the water inlet P is divided into two paths, one path passes through the central hole c of the main valve core, the main valve liquid resistance 4 communicates with the main valve spring chamber, and the other path passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com