Underwater piling machine

A technology of pile drivers and submersibles, which is applied to sheet pile walls, water conservancy projects, underwater structures, etc., can solve problems such as difficulties in bridge piers and impossibility of construction, and achieve the effect of expanding the water area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

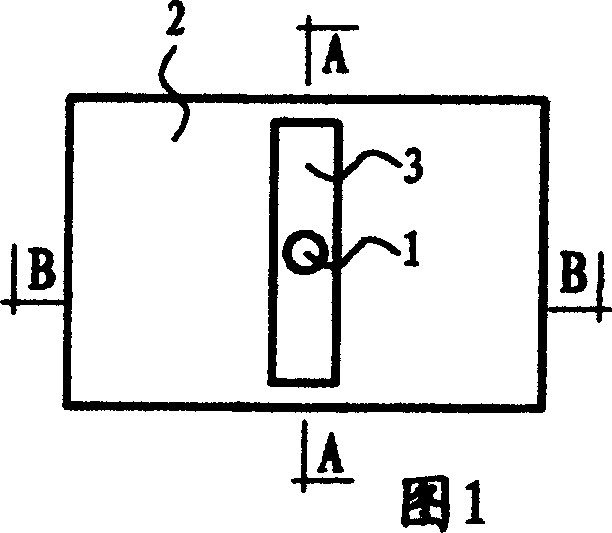

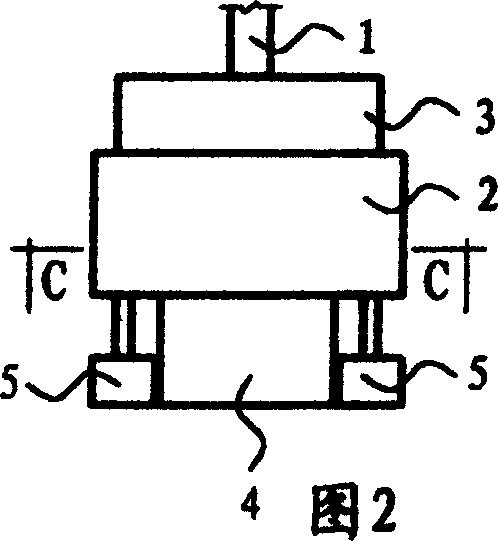

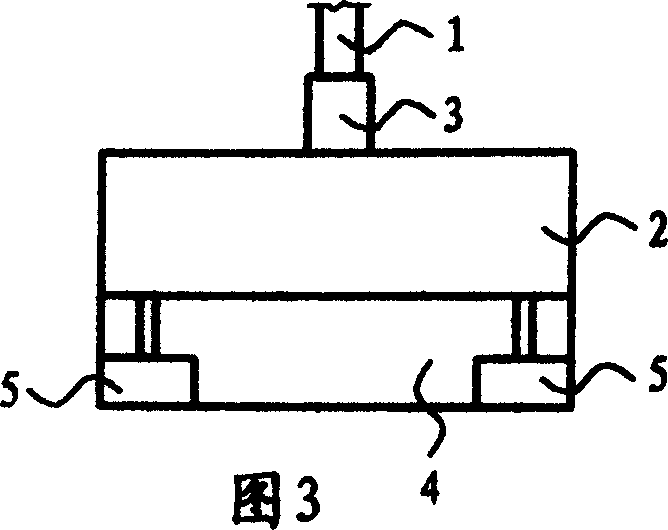

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0043] As shown in Figure 1-6, a diving pile driver includes an esophagus (1), a submersible (2), a water breaking chamber (4), four hydraulic legs (5), and several steel immersed tubes (9) , two pressure devices (10), several submersible drilling rigs (11), and several fasteners. Its submersible (2) is made up of material allocation bin (3), control room (6), water storage bin (7), pressure bin (8). The perforations (13) of several steel immersed tubes (9) are arranged on the bottom plate of the pressure chamber (8), and four guides (12) are arranged on the hole wall of each perforation (13). The steel immersed tube (9) is inserted in the perforation (13) on the bottom plate of the pressure chamber (8) and in the perforation (14) on the bottom plate of the water cut-off chamber (4), and the submersible drilling rig (11) is installed on the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com