Unidirectional clutch

A technology for one-way clutches and inner rings, applied in one-way clutches, clutches, automatic clutches, etc., to achieve the effects of improving versatility, no friction loss, and reducing the number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

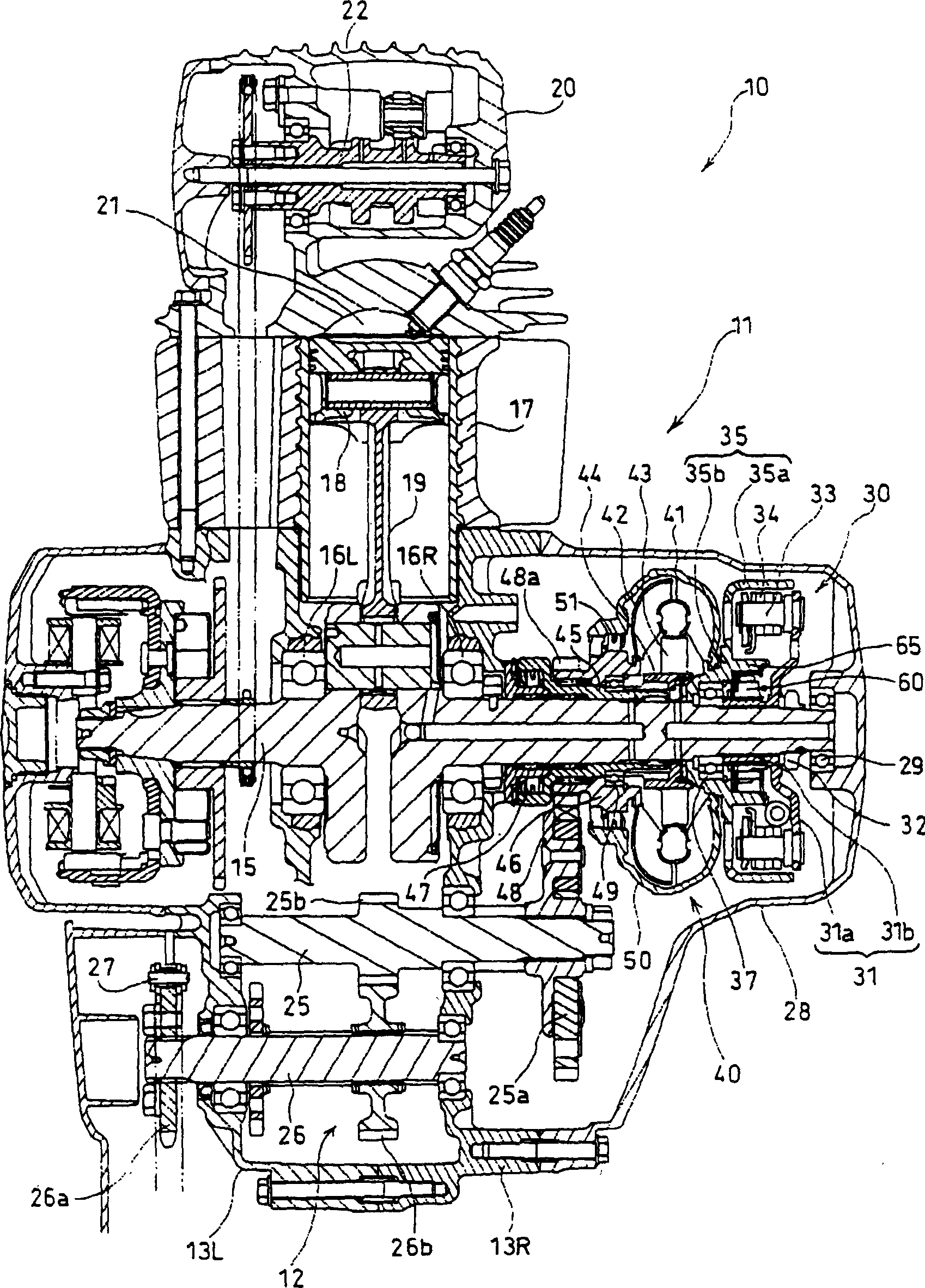

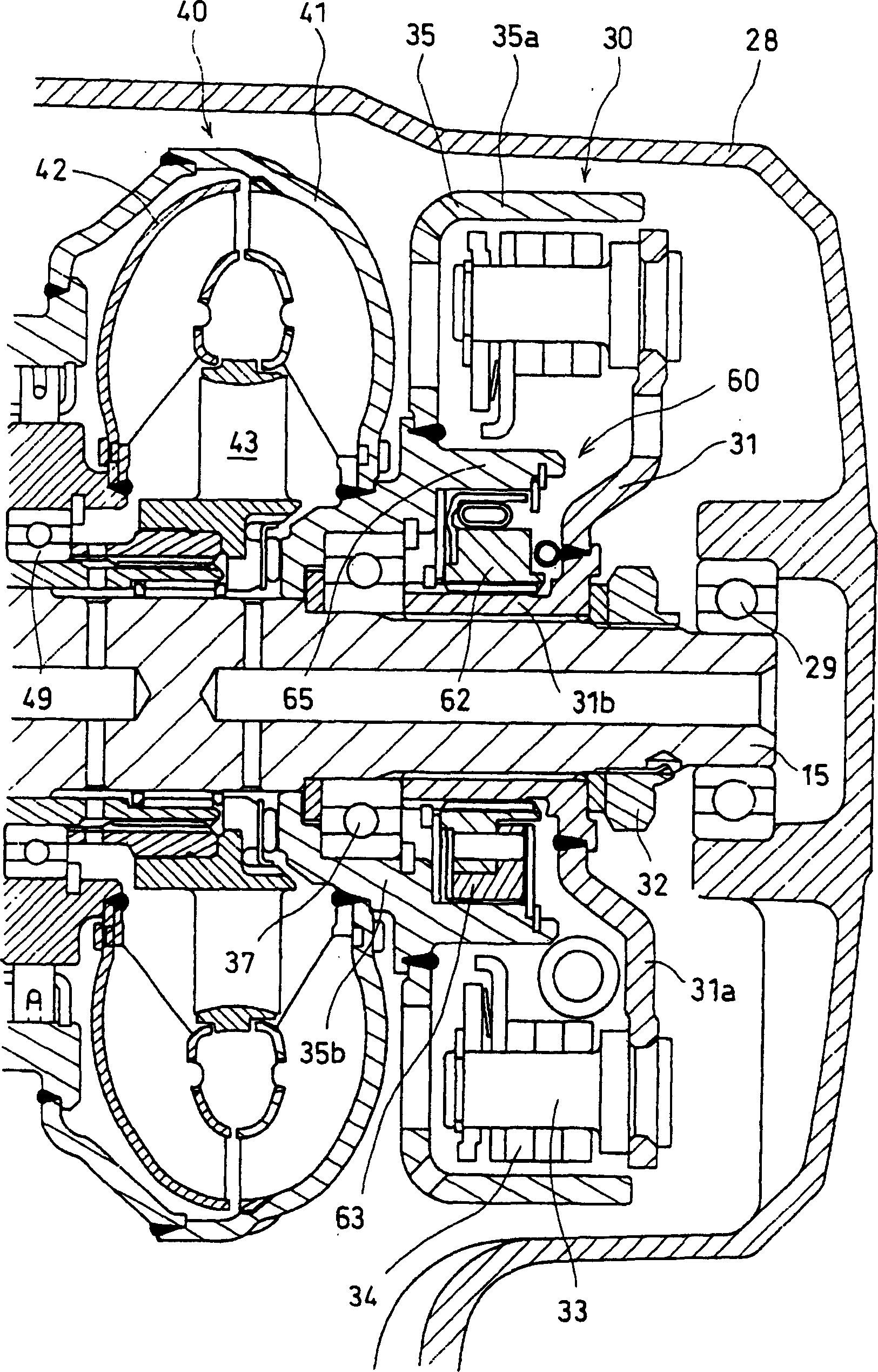

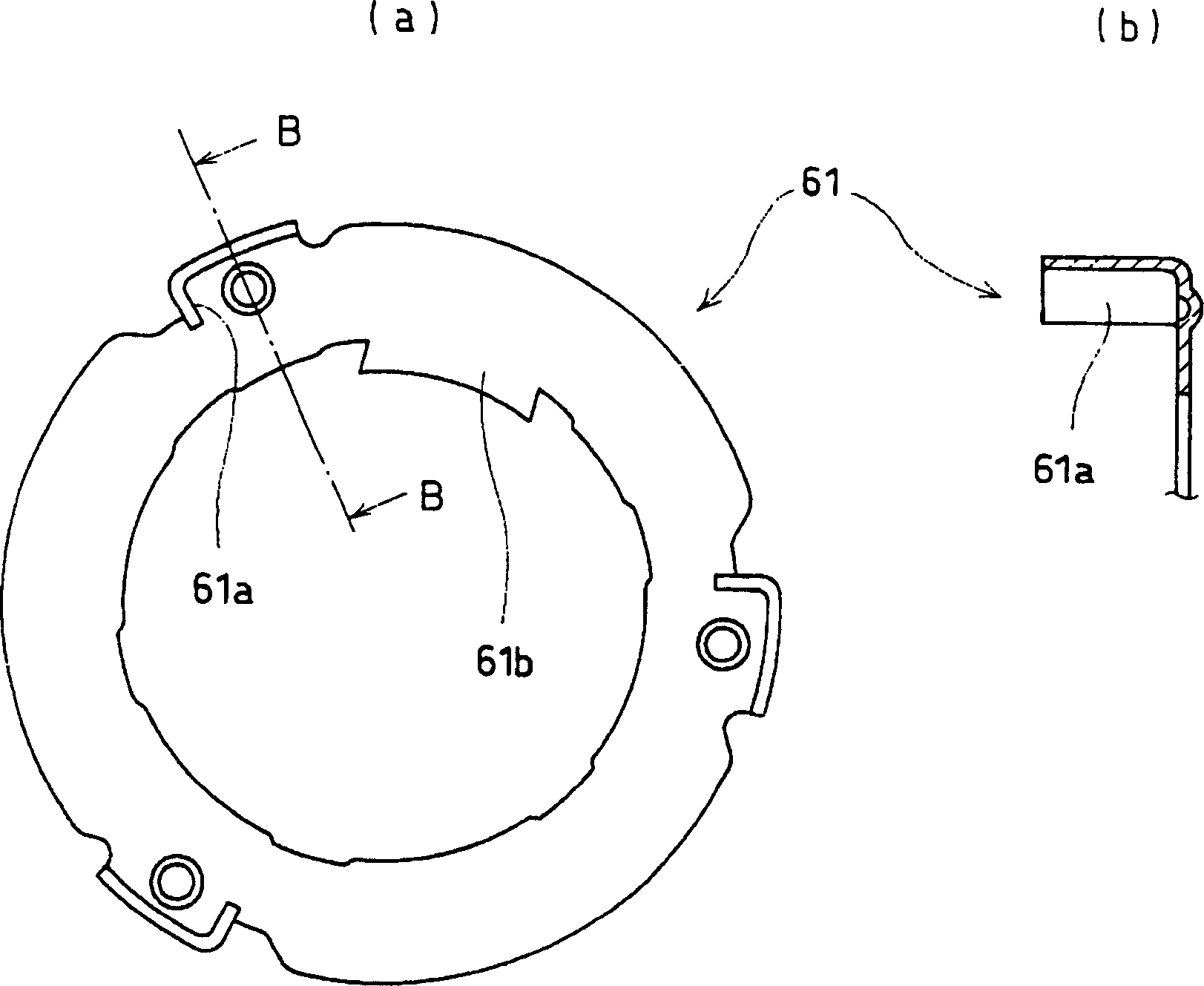

[0021] Below, the embodiment of the present invention is based on Figure 1 to Figure 9 Be explained. first, figure 1 It is a longitudinal sectional view of a power unit 10 for a motorcycle incorporating an embodiment of the one-way clutch of the present invention, figure 2 is to zoom in figure 1 Figures near the centrifugal starting clutch 30 and the one-way clutch 60 for engine braking in Fig.

[0022] The power unit 10 is constituted by an integrated internal combustion engine 11 and a load-side transmission mechanism 12 .

[0023] A crank chamber and a gear chamber are formed inside by combining the left and right halves of the left unit case 13L and the right unit case 13R, which integrate the crankcase of the internal combustion engine 11 and the gearbox of the transmission mechanism 12 .

[0024] The crankshaft 15 arranged to point to the left-right direction of the vehicle is supported by the respective left and right unit cases 13L, 13R via bearings 16L, 16R. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com