Highly clean flat green tea processing method

A processing method and clean technology, applied in the direction of tea, pre-extraction tea treatment, food science, etc., can solve the problems of not being able to become green high-grade tea, high content of dust bacteria, limited output, etc., to facilitate the killing of bacteria and chlorophyll damage Less, improve the effect of shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

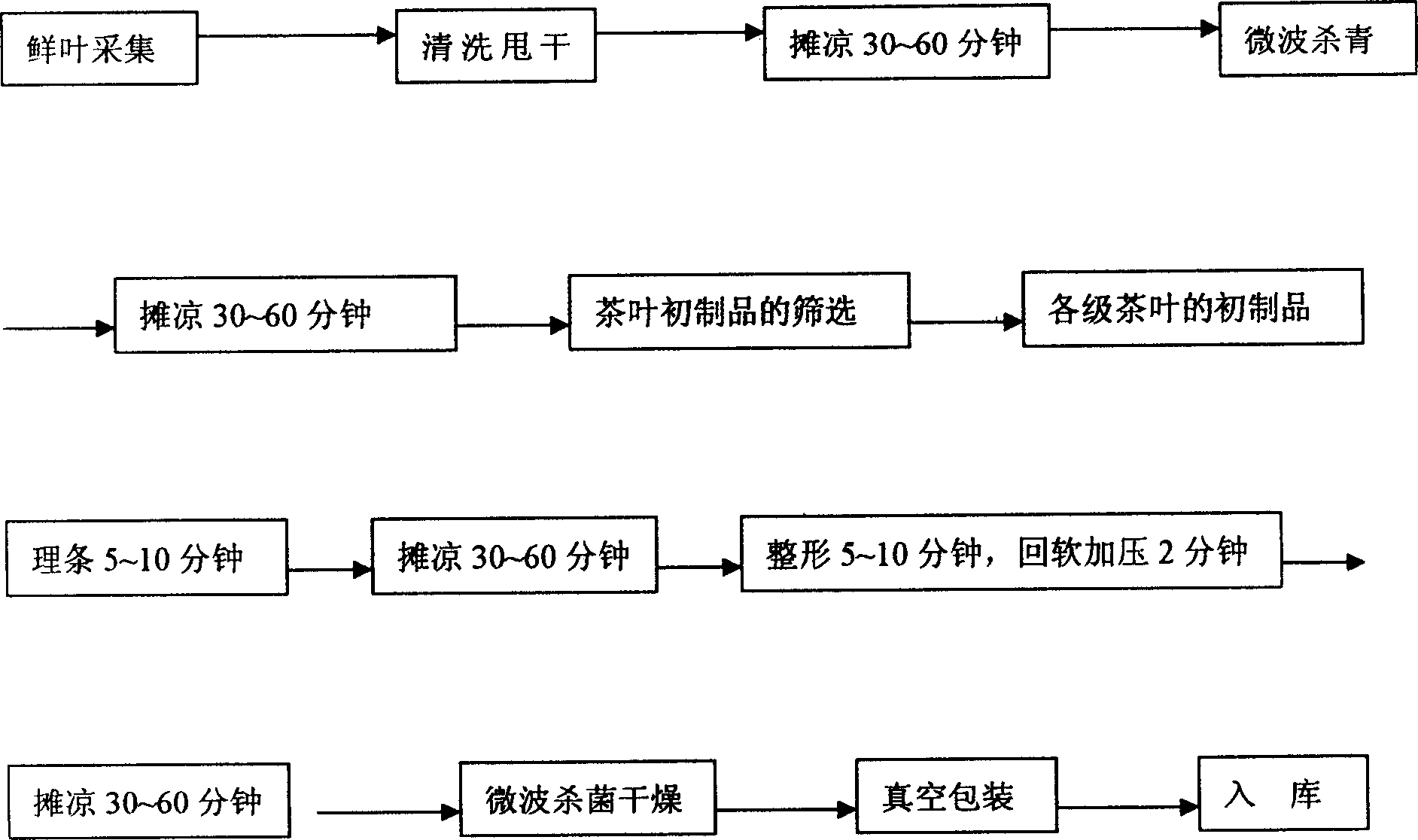

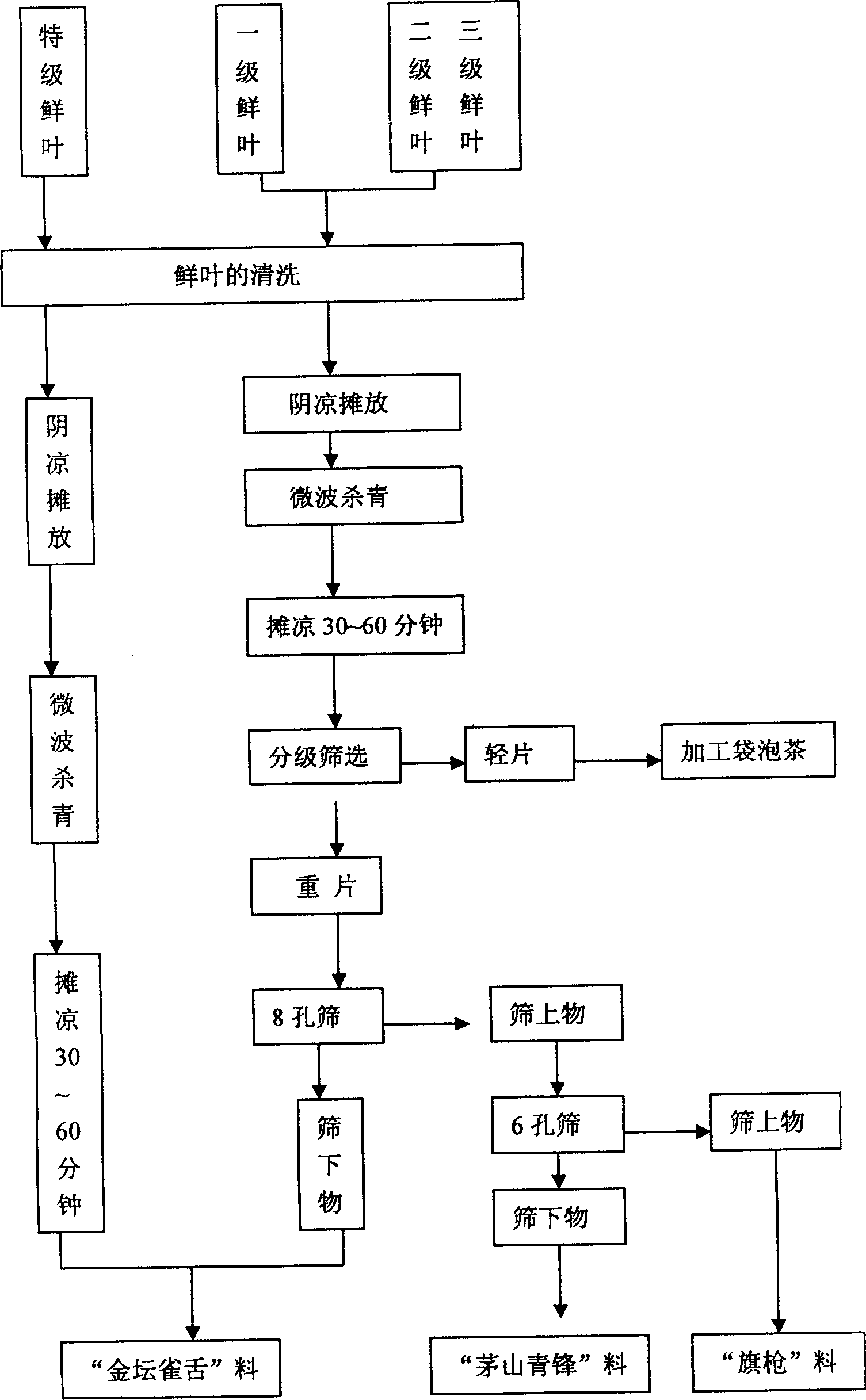

[0014] The present invention includes two stages of pre-processing and post-processing of flat green tea. The pre-processing section includes the sorting and collection of fresh leaves, washing, drying, shading, microwave curing, cooling, and screening; the post-processing section Including stripping, cooling, shaping, microwave sterilization and drying, and vacuum packaging; the time for microwave curing is to ensure that the moisture content of the tea after curing is maintained between 20% and 30%, and the general curing time is 100 to 160 seconds. ; The time of sterilization and drying is to ensure that the moisture content of the finished tea reaches 5% to 7%, and the sterilization and drying time should be greater than 15 seconds to ensure that no bacteria in the tea survive; the packaging is vacuum packaging, and other processes and current There are the same processing methods.

[0015] The specific preparation methods of the typical flat green teas "Golden Tanque Sponge",...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com