Method for manufacturing hollow brick with a core and special-purpose dies thereof

A technology of hollow bricks and molds, which is applied in the direction of manufacturing tools, molds, ceramic extrusion dies, etc., can solve the problems of low production efficiency and inability to produce hollow bricks, and achieve the effects of high production efficiency, easy industrial production, and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

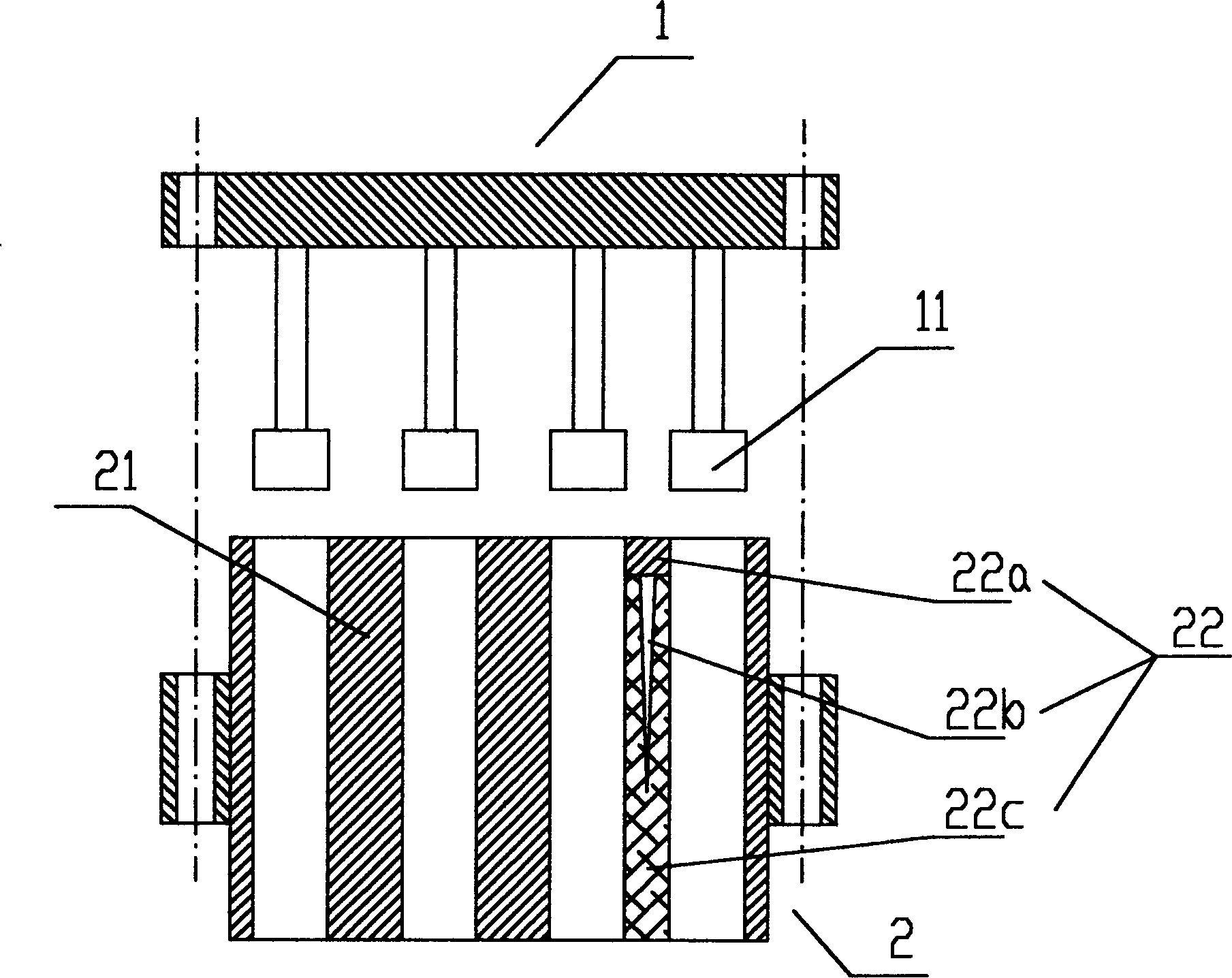

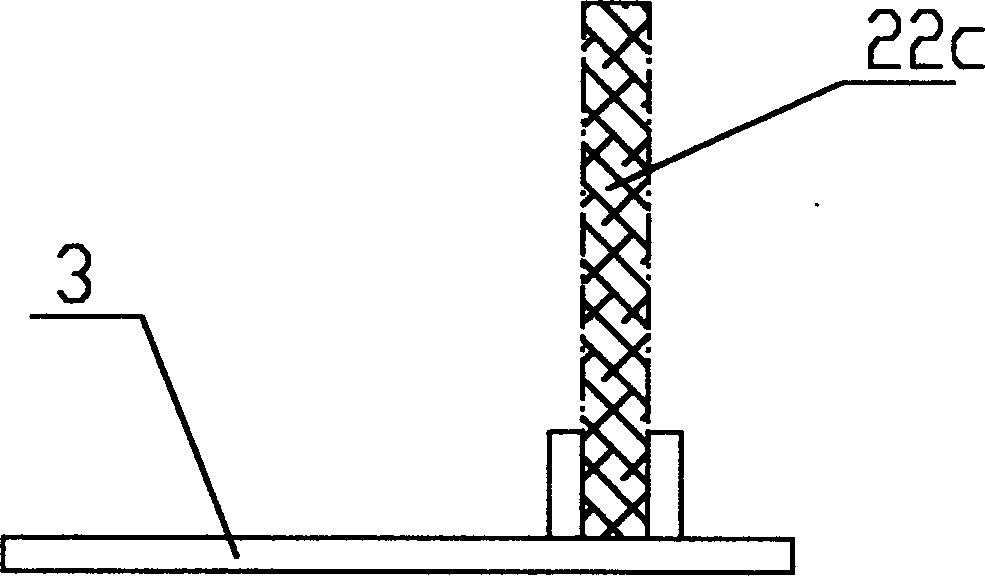

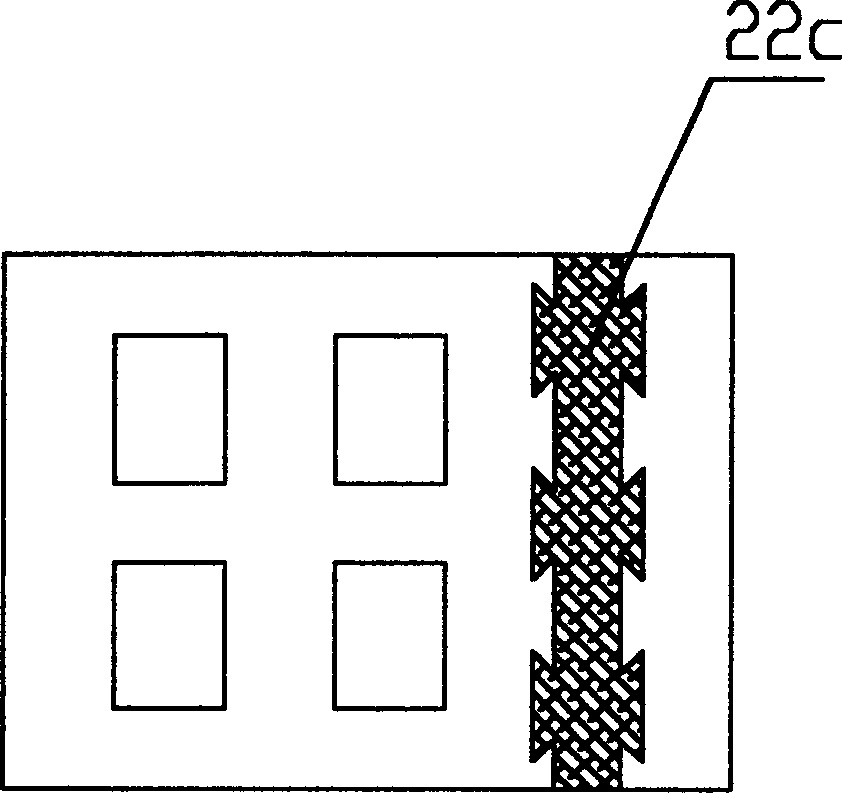

[0014] A method for manufacturing a hollow brick with a core includes the following steps: firstly, the filling core is fixed in the cavity of the lower forming mold as the core of the lower forming mold, and the fixing method is to set a filling core placement plate, and install the filling core on the placement On the board, move the placing plate with the filling core to the corresponding position under the lower forming mold, then drop the lower forming mold, so the filling core is inserted into the cavity of the lower forming mold, then lift the lower forming mold, and remove the placing plate , the filling core is placed; then the hollow brick raw material is poured into the lower molding die, the upper extrusion die is dropped, and the stamping head of the upper extrusion die vibrates and stamps the raw material, the hollow brick can be formed, and the filling core is extruded in the Inside the hollow brick, lift the lower molding die and the upper extrusion die, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com