Shift controlling method of clutch-less operation for parallel type mixed power automobile

A hybrid vehicle, clutchless technology, applied in the direction of hybrid vehicles, joint control, electric vehicles, etc., can solve the problems of long power interruption time, fast wear of the clutch, large shifting impact, etc., to prolong the life of the clutch and accelerate the vehicle Enhanced performance and reduced shift shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following detailed description will be given with reference to the accompanying drawings in conjunction with the embodiments, so as to have a deeper understanding of the purpose, features and advantages of the present invention.

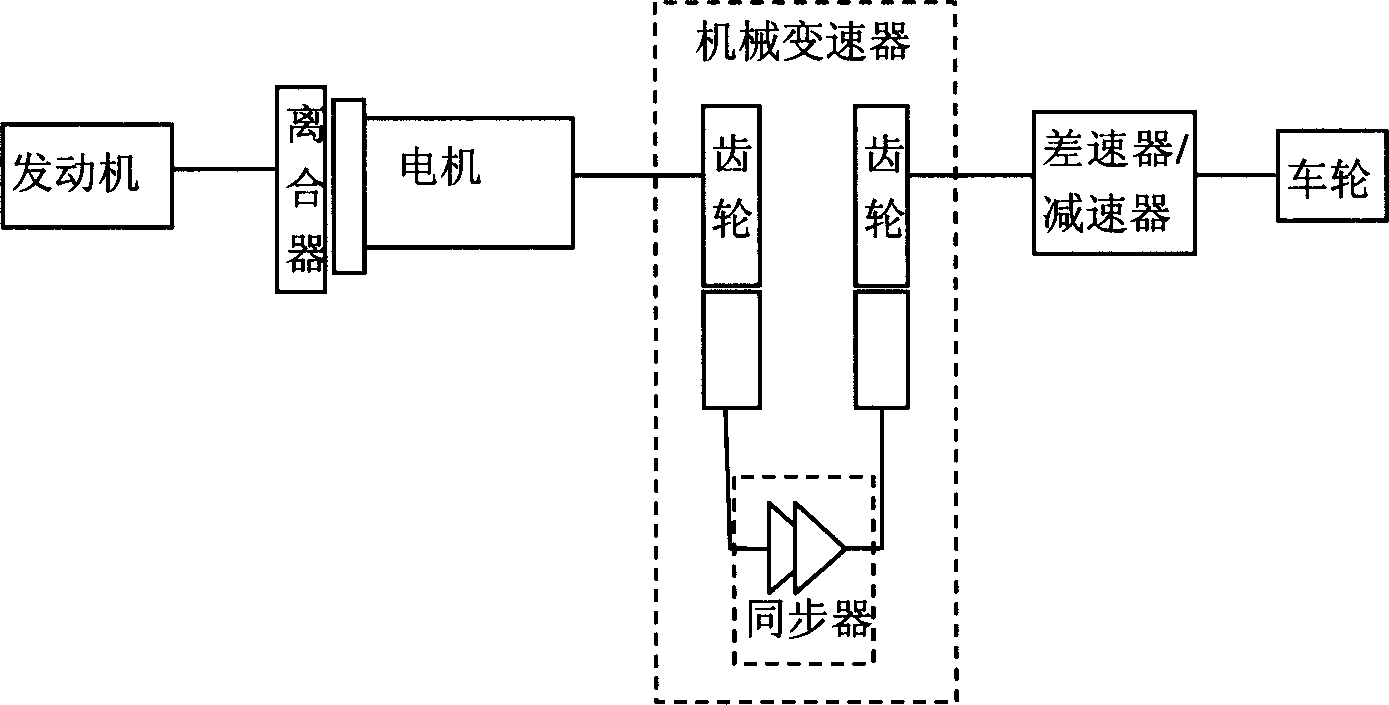

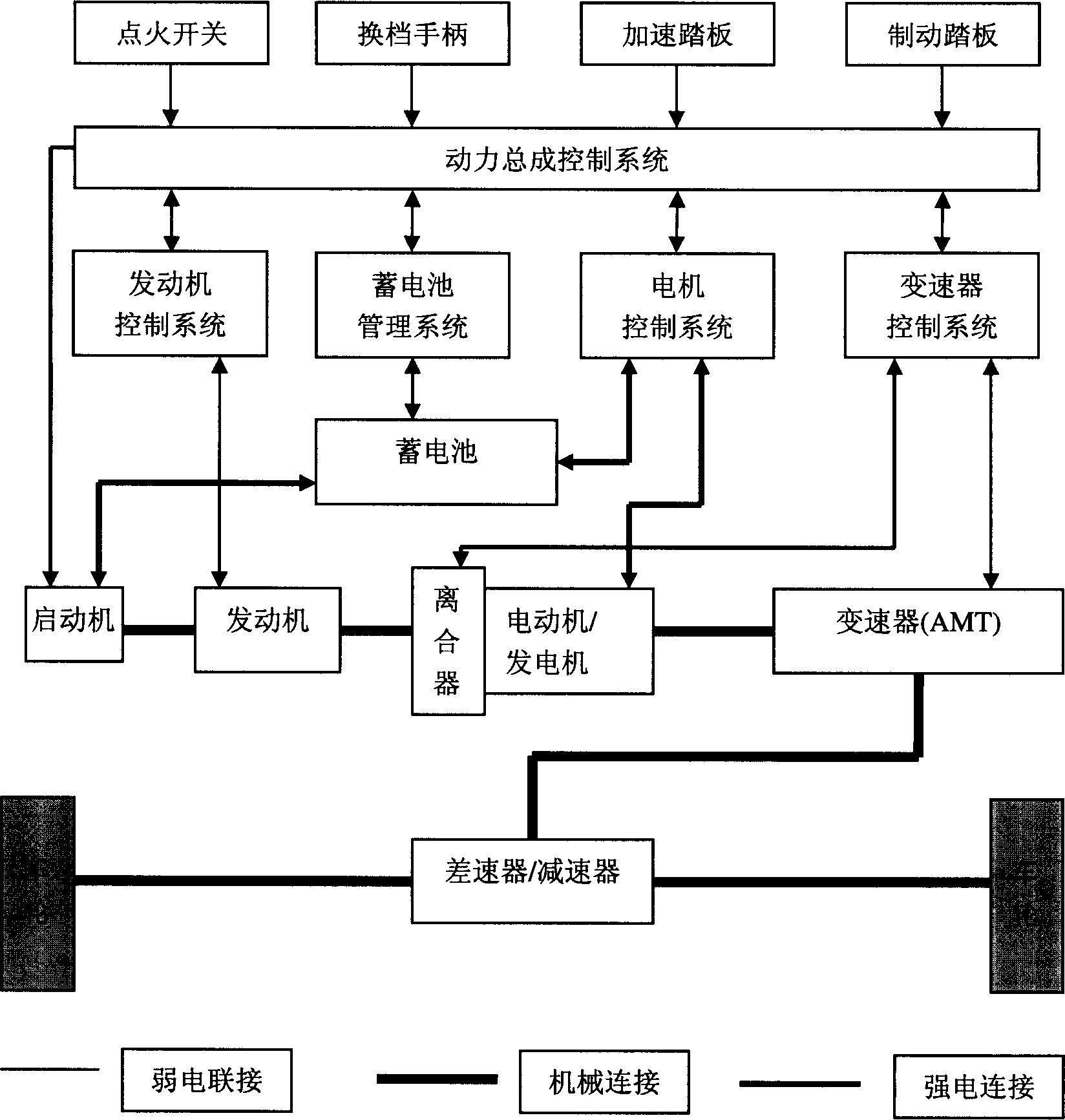

[0039] Such as figure 1 As shown, the power system of a parallel hybrid car using AMT (automated manual transmission) is mainly composed of engine, clutch, main motor and manual transmission (including synchronizer). This power system is similar to the power system of a traditional internal combustion engine + manual transmission, both of which require shift control.

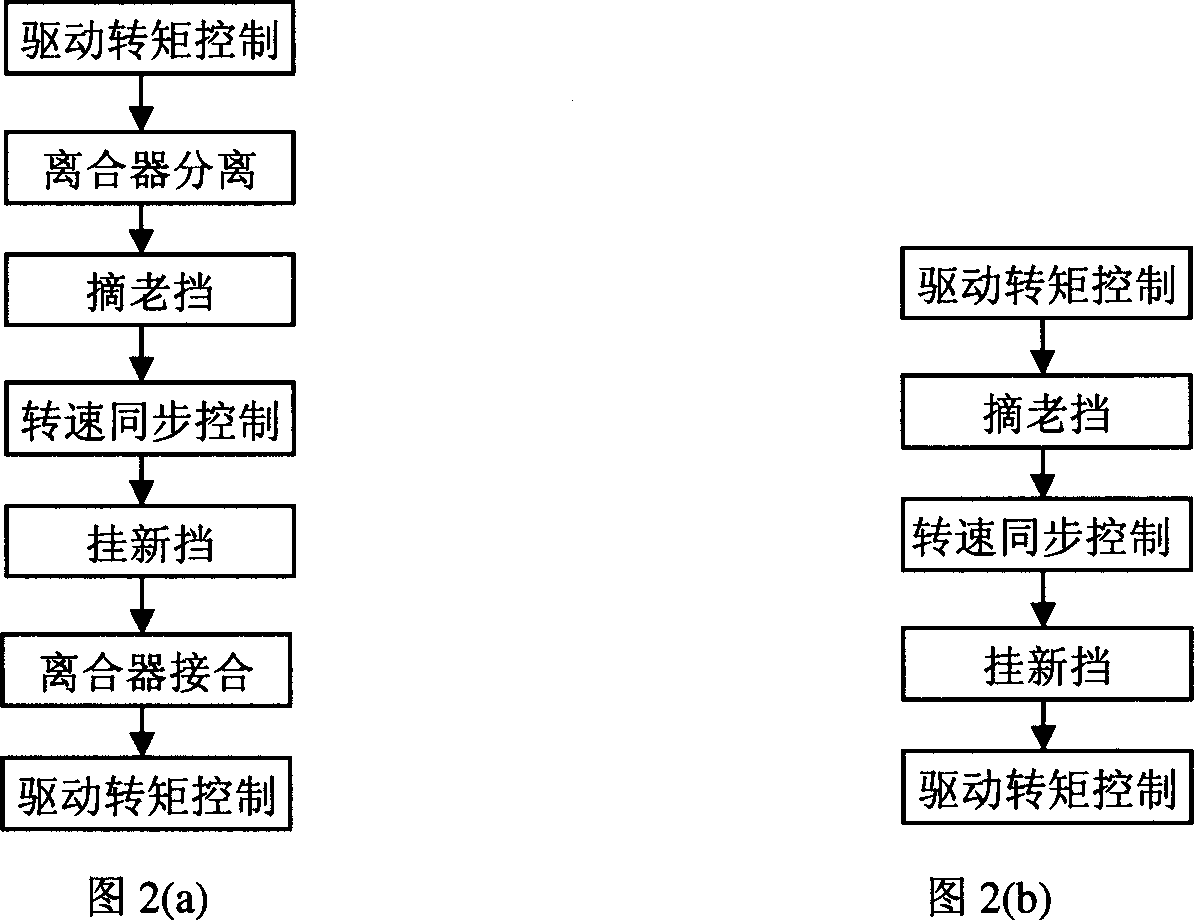

[0040] Such as figure 2 As shown, the traditional shift control process with clutch operation is divided into seven major steps: driving torque control, disengaging the clutch, removing the old gear, synchronizing the speed, engaging the new gear, engaging the clutch, and driving torque recovery control (see figure 2 (a)), it is necessary to disengage and engage the clut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com