Recovery method for waste water of 1,4-dihydroxyanthraquinone production

A technology of dihydroxyanthraquinone and recovery method, which is applied in the direction of chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the problems of waste of resources, environment, pollution, poor effect of treatment and recovery technology, etc. To achieve the effect of eliminating pollution and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

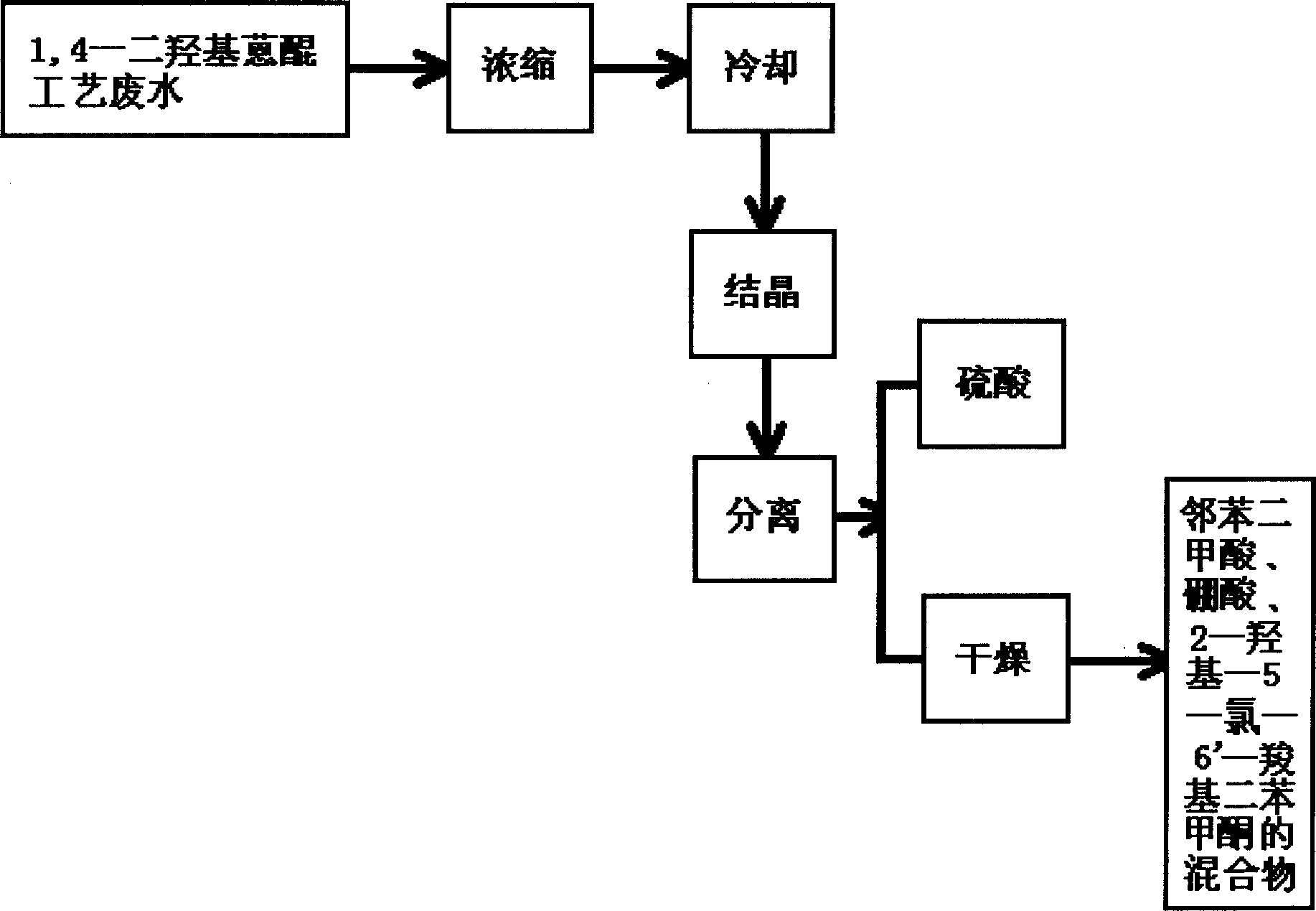

Method used

Image

Examples

Embodiment 1

[0018] Put 1750ml of waste water into a 2000ml beaker, and add a few grains of zeolite, place the beaker containing the liquid on a 1KW electric furnace, heat it to boiling, evaporate and concentrate it until the concentration of sulfuric acid in the solution is 20%, stop heating, and then put the beaker containing the concentrated liquid into a water bath Cool in medium, and keep stirring with a glass rod. When the material is cooled to 30°C, a large amount of crystals will precipitate and stay for one hour. Then filter the slurry on a Buchner funnel to obtain 800ml of 20% sulfuric acid solution. The filter cake is in CLS101- Dry in an E-type oven at 100°C-110°C to obtain 25g of a mixture of phthalic acid, boric acid, and 2-hydroxyl-5-chloro-6'-carboxybenzophenone.

Embodiment 2

[0020] Put 1750ml of waste water into a 2000ml beaker, and add a few grains of zeolite. Put the beaker containing the liquid on a 1KW electric furnace and heat it to boil. When the concentration of sulfuric acid in the solution reaches 30%, stop heating, and then put the beaker containing the concentrated liquid into a water bath. Cool in medium temperature and keep stirring with a glass rod. When the material is cooled to below 15°C, a large amount of crystals will precipitate out and stay for one hour. Filter the slurry on a Buchner funnel to obtain 570ml of 30% sulfuric acid solution. The filter cake is in CLS101- Dry in an E-type oven at 100°C-110°C to obtain 31g of a mixture of phthalic acid, boric acid, and 2-hydroxyl-5-chloro-6'-carboxybenzophenone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com