Method for treating hardly degradable organic water using electrochemical turntable

An organic wastewater and electrochemical technology, applied in the field of environmental technology and electrochemistry, can solve the problems of slow mass transfer of flat plate electrodes, increase of dissolved oxygen in liquid film, etc., achieve both oxidation efficiency and catalytic effect, make full use of space, and speed up exchange and renewal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0011] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

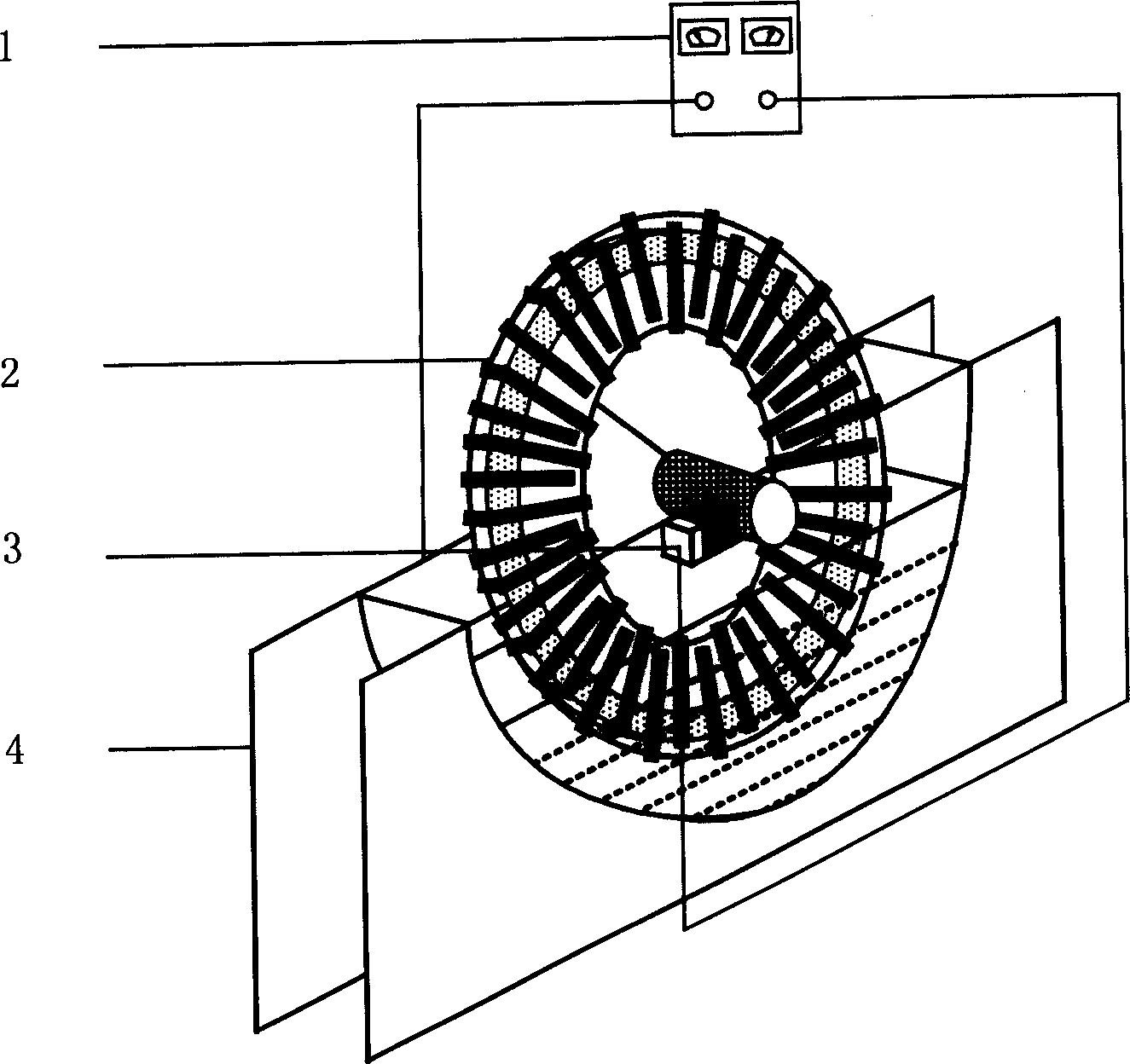

[0012] figure 1 It is a schematic diagram of the structure of the electrochemical turntable used in the method of the present invention. This is only a schematic illustration of a single turntable, and multiple turntables can be connected in parallel in an actual device.

[0013] Such as figure 1 As shown, on an electrochemical turntable 2, anodes and cathodes are evenly and alternately arranged at different intervals, the anodes and cathodes are respectively connected by wires, and then connected to the two poles of the DC power supply 1 through carbon brushes 3 respectively. The lower part of the electrochemical turntable 2 is immersed in the solution in the electrolytic cell 4, and the upper part is exposed to the air. The motor is used to drive the turntable to rotate, and the rotation of the turntable accelerates the e...

Embodiment 1-3

[0015] Embodiment 1-3: the influence of different rotating speeds on chroma removal rate

[0016] time (minutes)

[0017] When the rotation speed is 0 rpm, it is equivalent to the traditional electrolysis method of inserting fixed electrodes. The electrolysis effect is not as good as that of rotation, and the electrolysis effect increases with the acceleration of rotation speed.

Embodiment 4-6

[0018] Embodiment 4-6: the influence of different cathode materials on chroma removal rate

[0019] time (minutes)

[0020] Copper, iron, and titanium-based oxides all work well as cathode materials. In contrast, iron is easy to rust, and the production cost of titanium-based oxides is high, so it is more appropriate to choose copper as the cathode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com