Dust cloud combustion furnace

A dust cloud and combustion furnace technology, applied in the field of combustion furnaces, can solve problems such as low combustion efficiency, poor feeding and transportation, and easy failure of equipment, so as to reduce combustion pollution, expand the allowable particle size range, and reduce crushing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

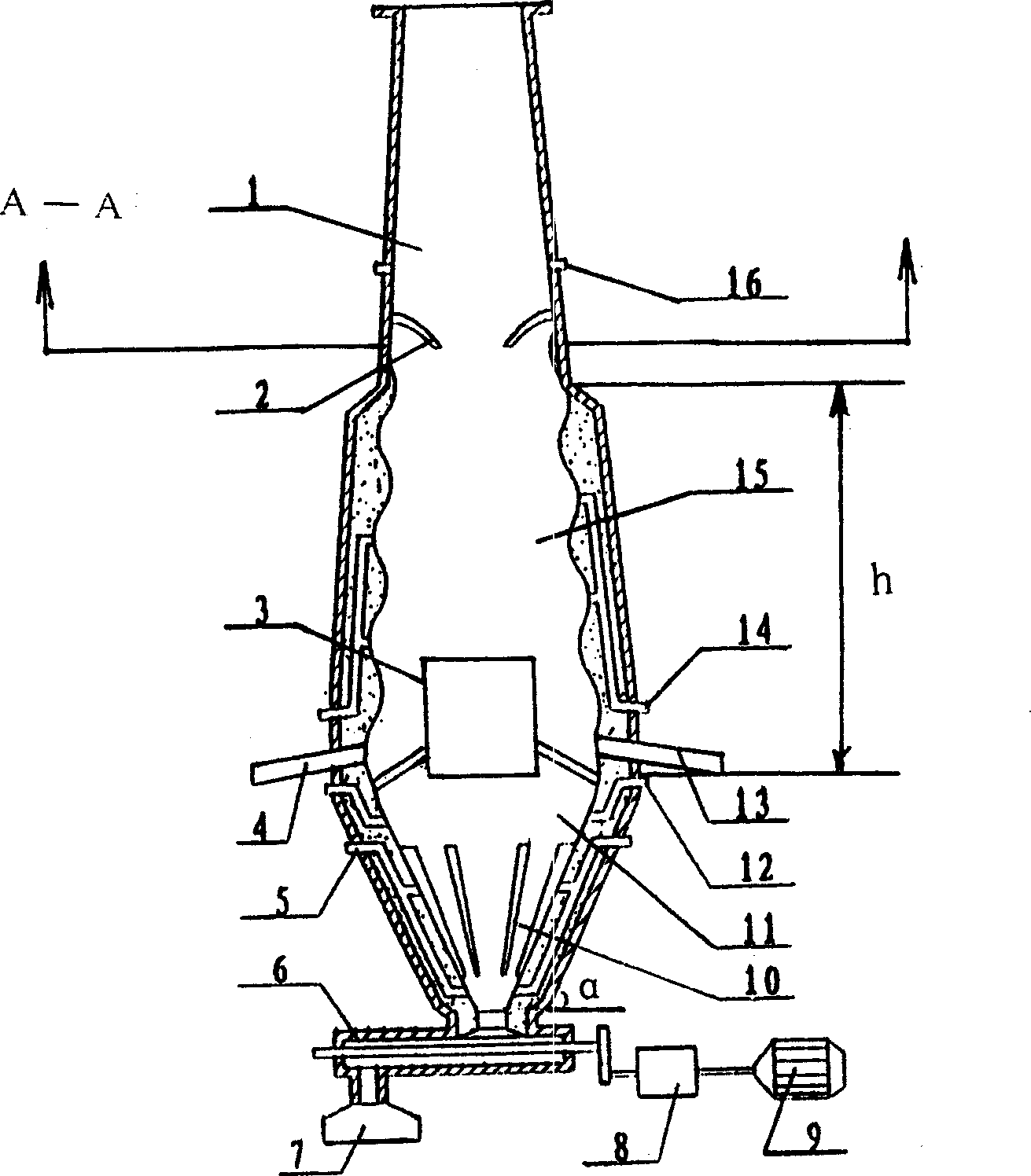

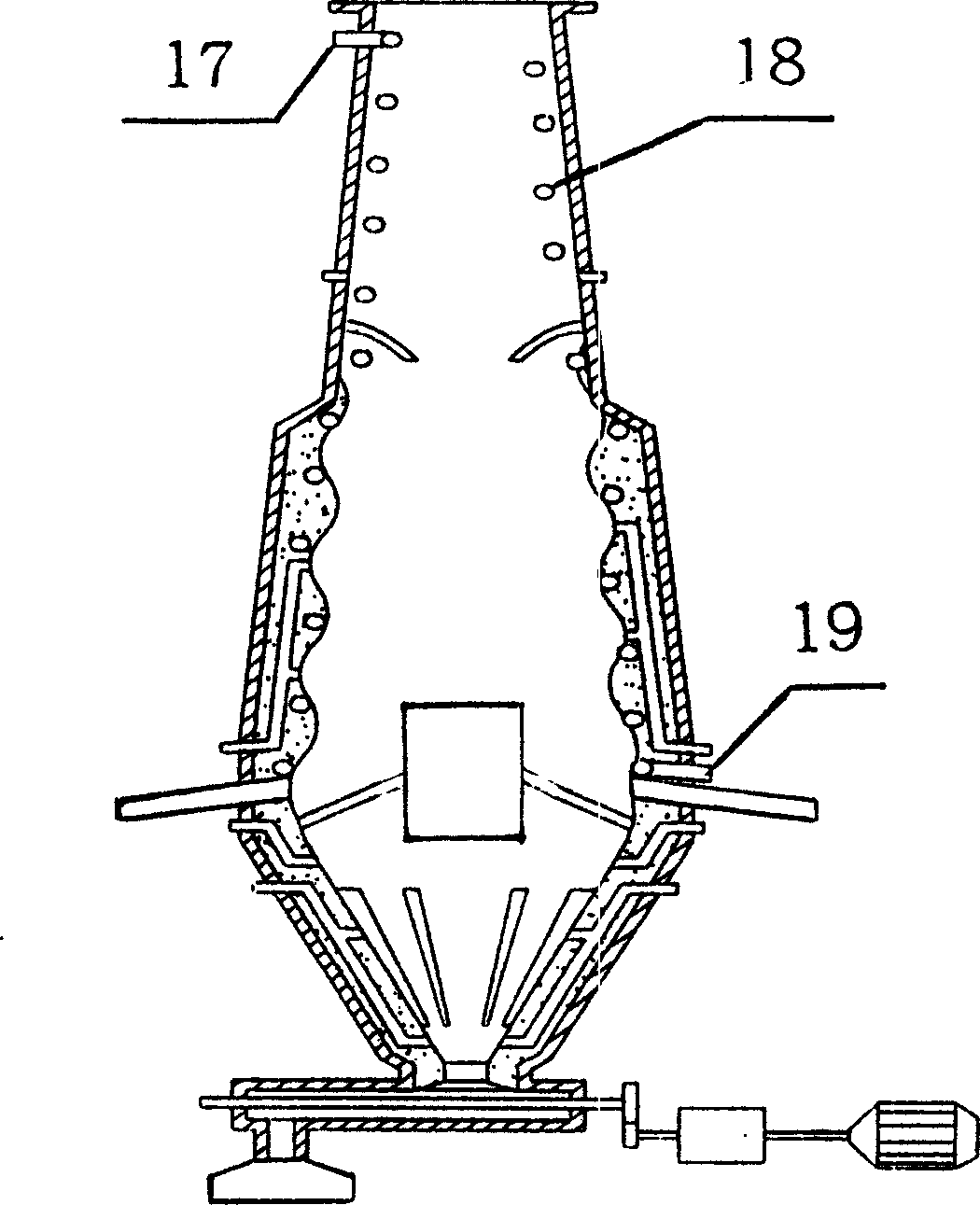

[0016] Depend on figure 1 , figure 2 As shown, the inner wall surface in the middle part of the furnace body is in a spiral shape, and the heating body 3 is arranged in the middle of the furnace, and the ash baffle 2 is arranged on the upper part of the furnace body wall. There is a dust cloud inlet 4, a diesel igniter inlet 13 and a primary air inlet 14, forming a gasification combustion chamber 15 between the animal heat body 3 and the ash baffle 2; the lower part of the furnace body is a closed cone, and the end of the cone is The ash outlet 7 is set, and on the wall of the furnace body, there are secondary air inlets 12 and water vapor inlets 5 below the animal heat body 3 to form a secondary gasification chamber 11; There are three air inlets 16 on the top, and a residual gas combustion chamber 1 is formed between the ash baffle 2 and the top of the furnace body.

[0017] A heat conducting sheet 10 may be provided on the wall of the furnace body of the secondary gasifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com