Method for mfg. colour yarn by high speed elasticity spinning machine

A high-speed elastic and silk machine technology, applied in the direction of textiles and papermaking, can solve the problems of low elastic performance and inability to produce high value-added colored silk products, and achieve high value-added effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

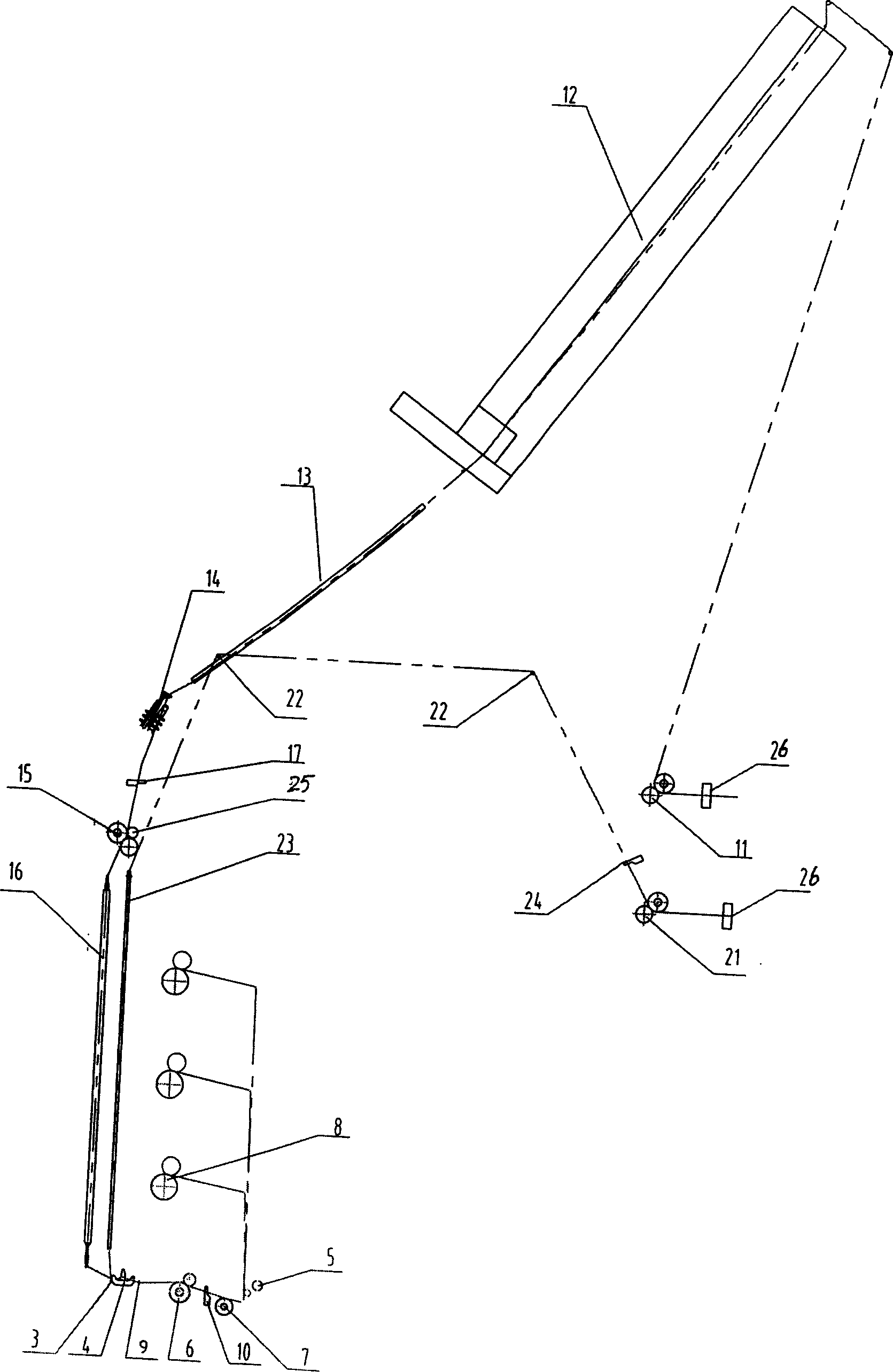

[0016] A kind of method that utilizes the high-speed elastic yarn machine of the present invention to manufacture fancy yarn, on the original company's high-speed elastic yarn machine, a second feeding roller 21, a wire guide wheel 22, a wire guide tube 23, a wire guide 3, Network nozzle 4 and lower suction pipe 5, the facility that increases is all fixed on the frame of former stretch yarn machine. The method includes the following steps:

[0017] A) The first POY yarn is drawn out from the raw yarn frame, passes through the first feeding roller 11 of the high-speed elastic yarn machine, enters the deformation heating box 12, passes through the cooling device 13, the post-false twister 14, and then enters through the middle roller 15 The sizing hot box 16, after being drawn out by the sizing hot box 16, is sucked by the lower suction pipe 5;

[0018] B) The second wire FDY is drawn out from the original wire frame, and enters the wire guide tube 23 after passing through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com