Knitting structure, method and apparatus

A technology of knitting and knitting yarn, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of poor mechanical properties of multi-axial knitting structures, and achieve the effects of improving mechanical properties, enhancing binding capacity, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

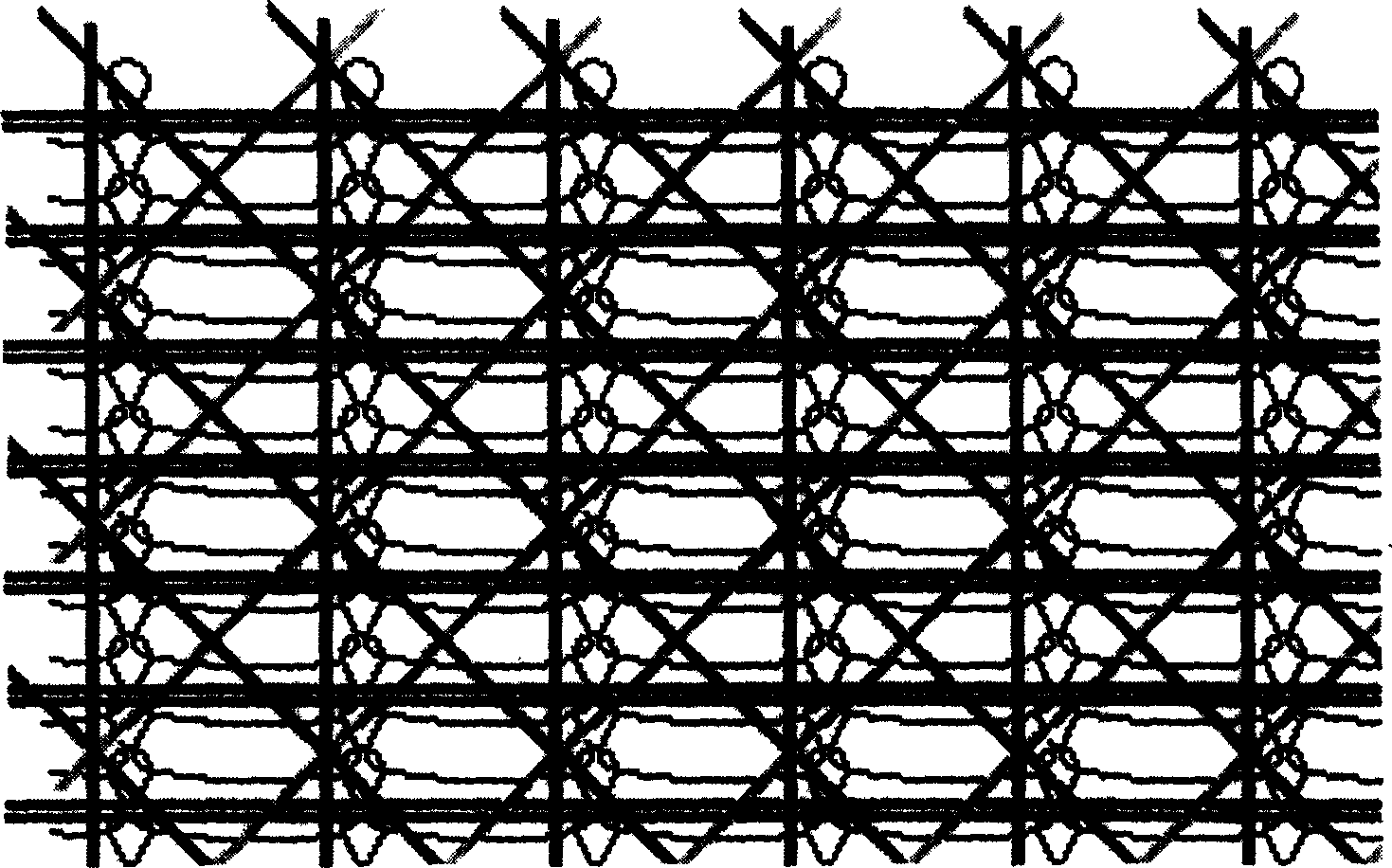

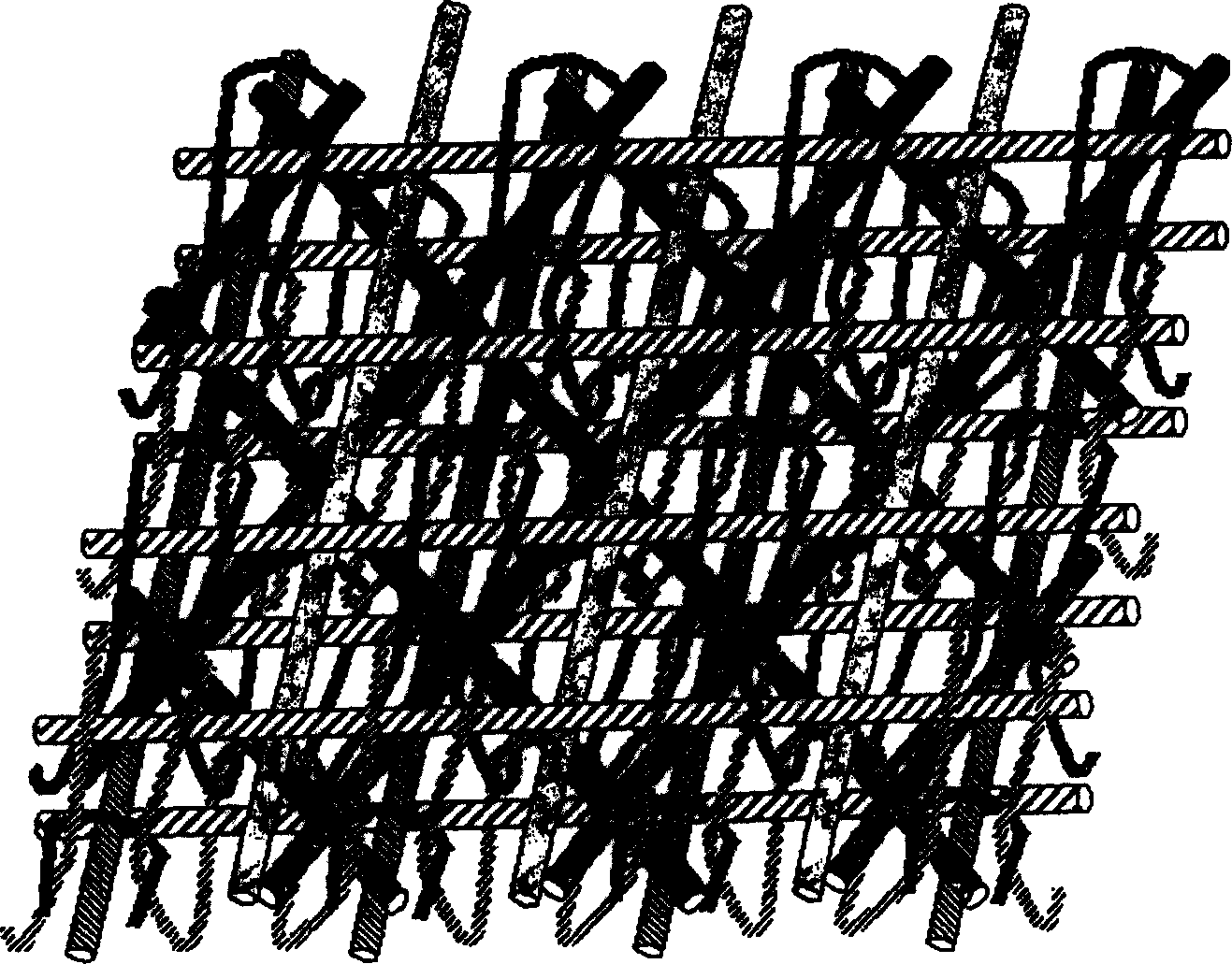

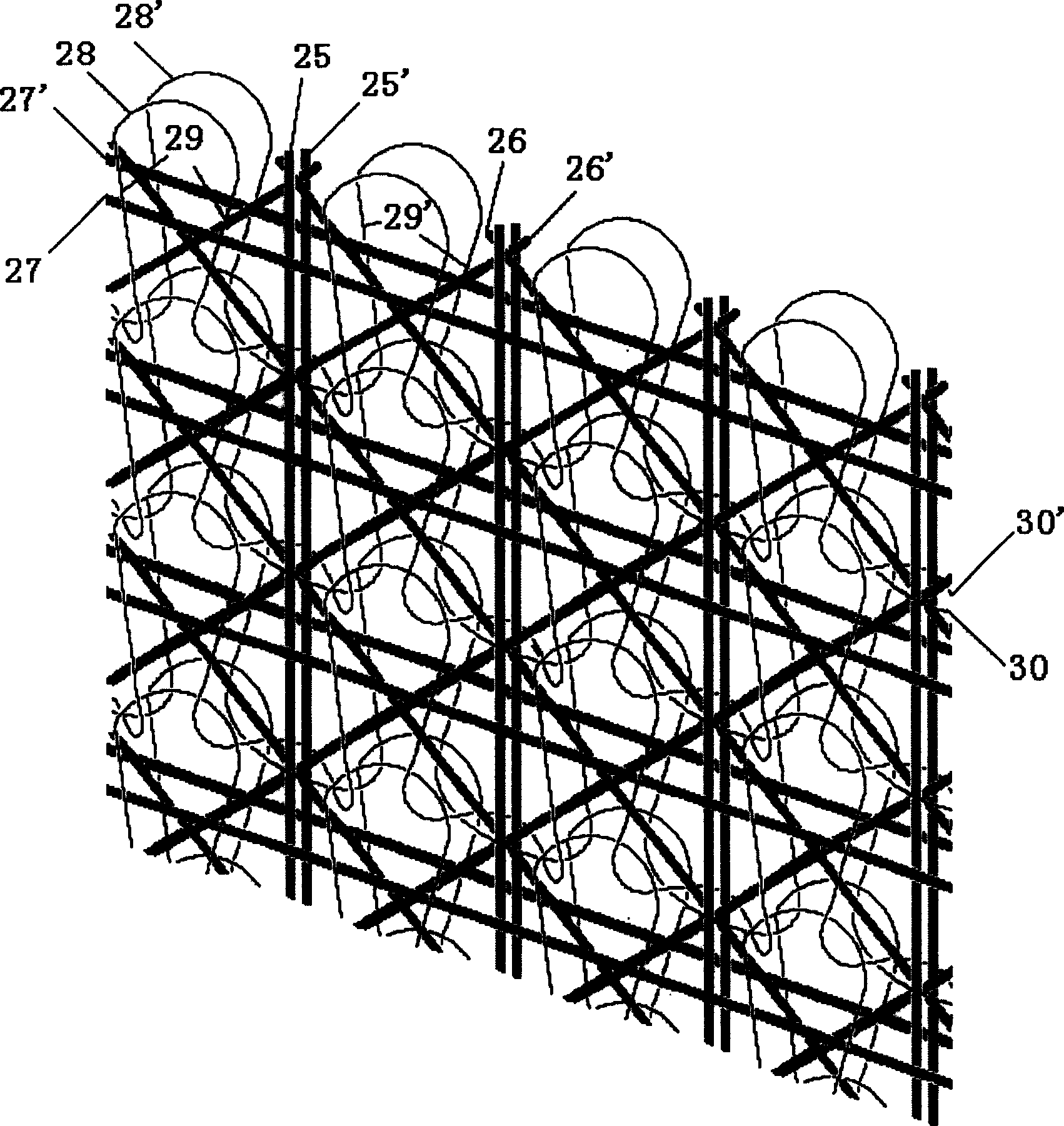

[0022] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing, by image 3 , Figure 4 and Figure 5 It can be seen that the multiaxial reinforced weft knitting structure of the present invention includes two weft plain stitches 28, 28', two sets of warp yarns 25, 25', two sets of weft yarns 27, 27', and one set of -45° oblique yarns 26 And a set of +45° diagonal yarn 26'. Warp yarns 25, 25', weft yarns 27, 27' and weft flat stitches 28, 28' are symmetrically configured, oblique yarns 26, 26' are located inside warp yarns 25, 25', and weft yarns 27, 27' are located inside warp yarns 25, 28'. 25' outside; weft yarns 27, 27', warp yarns 25, 25' and oblique yarns 26, 26' are lined into the weft flat stitches 28, 28' in a straight manner, and are respectively covered by their coil posts 29, 29' and the sinker arcs 30, 30' are tied, which enhances the binding ability of the knitting yarn to the warp, weft and obliqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com