Washing machine and washing method

A washing method and washing machine technology, applied to other washing machines, washing devices, chemical instruments and methods, etc., can solve the problems of weakening the washing effect of alkaline detergent, reducing the amount of detergent used, and reducing the amount of detergent used, so as to achieve satisfactory washing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

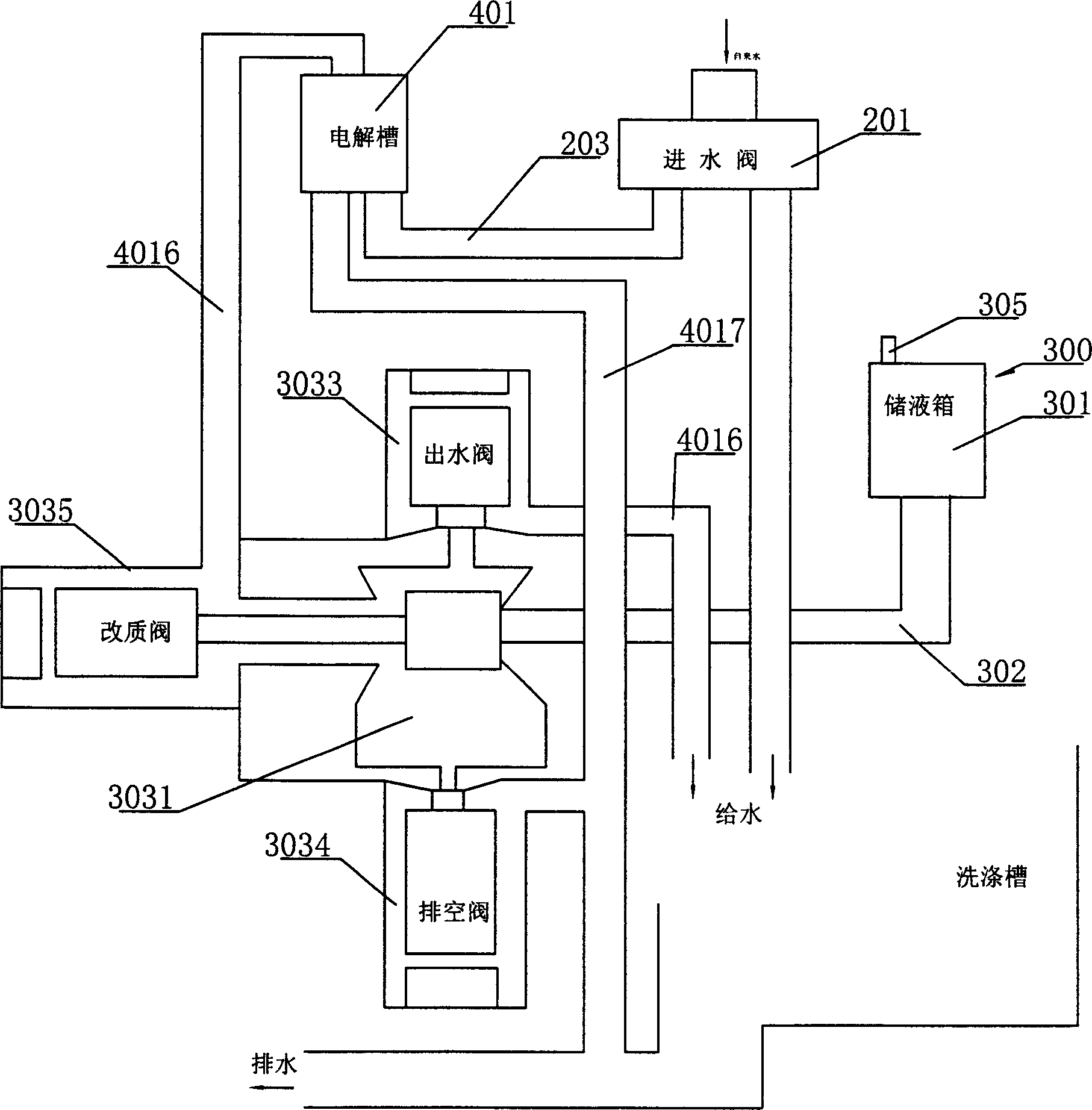

[0101] Example 1, when the volume of the buffer zone 3031 is 1ml, the precision of the washing machine control system can be achieved by passing through, and the required reforming solution is 3ml, then the control process of one-time liquid delivery is completed first.

[0102] First, close the water supply valve and the electrolysis device, control the emptying valve 3034 and the water outlet valve 3033 to act (open) at the same time, and the action time T1 is 6 seconds, and the liquid in the buffer zone 3031 and the buffer zone 3031 to the circuit of the washing tub Fully empty, turn off the emptying valve 3034 and the water outlet valve 3033, while closing the emptying valve 3034 and the water outlet valve 3033, the air valve 304 installed on the liquid storage tank 304 is opened to ensure that the pressure of the liquid storage tank 304 is consistent with the The external air pressure is balanced so that the liquid in the tank can be discharged smoothly. After T2 time is 2...

Embodiment 2

[0104] Control method with the flow rate of reforming fluid valve 3035 as the measurement unit

[0105] The volume of the buffer zone 3031 does not need to be set, but it is larger than the capacity of the reforming fluid that needs to be added. The amount of the reforming fluid that needs to be added is related to the T3 time that controls the action of the reforming fluid valve 3035. It is obtained by calculating the ratio of the amount of reforming fluid to the flow rate of the reforming fluid valve 3035, and the flow rate of the reforming fluid valve 3035 is inherent in itself. You only need to input the amount of reforming fluid to be added into the computer board to obtain the T3 The time of T3 can also be calculated artificially.

[0106] First, close the water supply valve and the electrolysis device, control the emptying valve 3034 and the water outlet valve 3033 to operate simultaneously, and the operating time T1 is 7 seconds, and fully drain the liquid in the buffer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com