Ice making mechanism for ice maker

A technology of ice maker and ice water, which is applied in ice making, ice making, lighting and heating equipment, etc. It can solve the problems of poor ice making efficiency, melting of ice mass, dark appearance of ice mass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (summary)

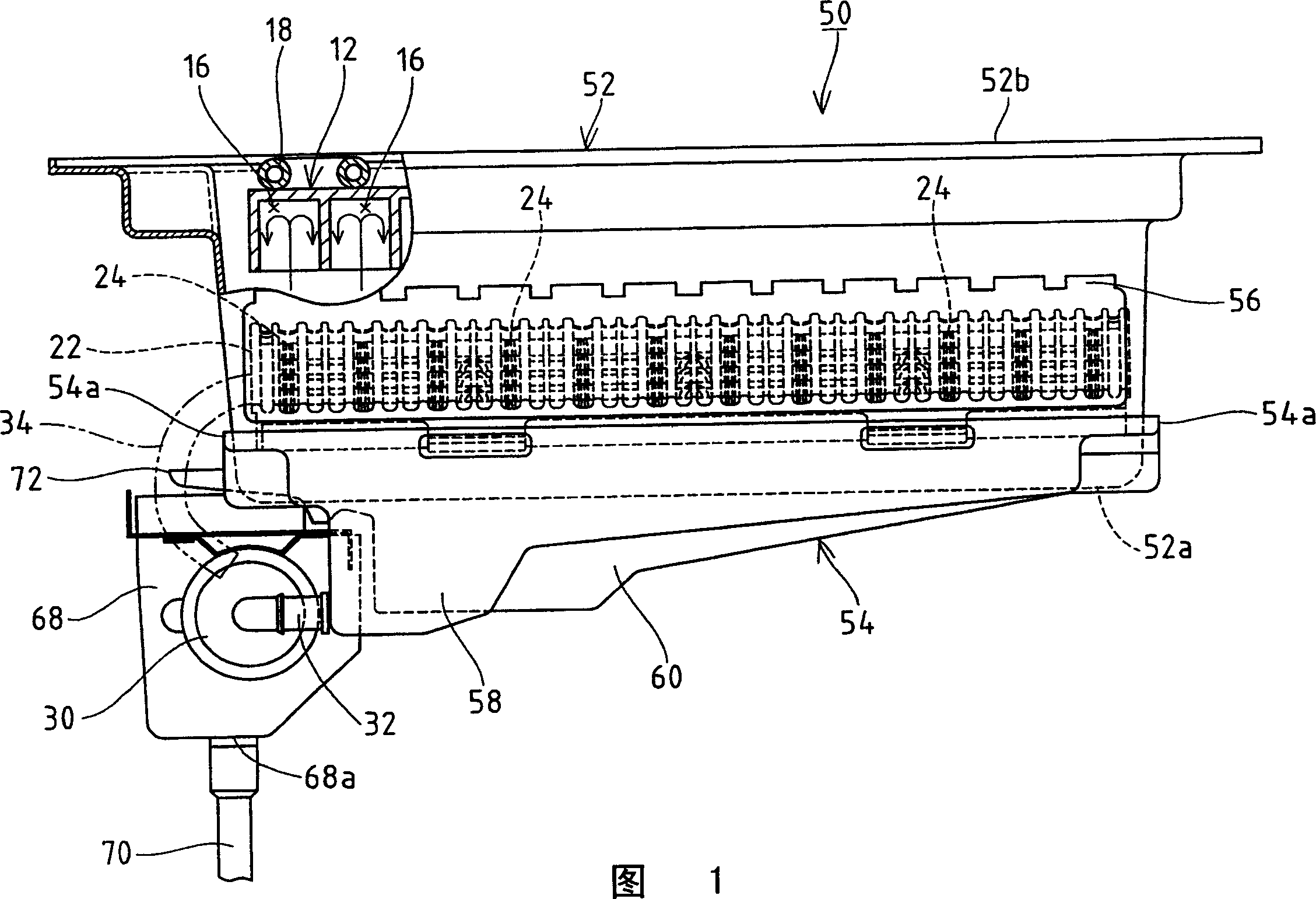

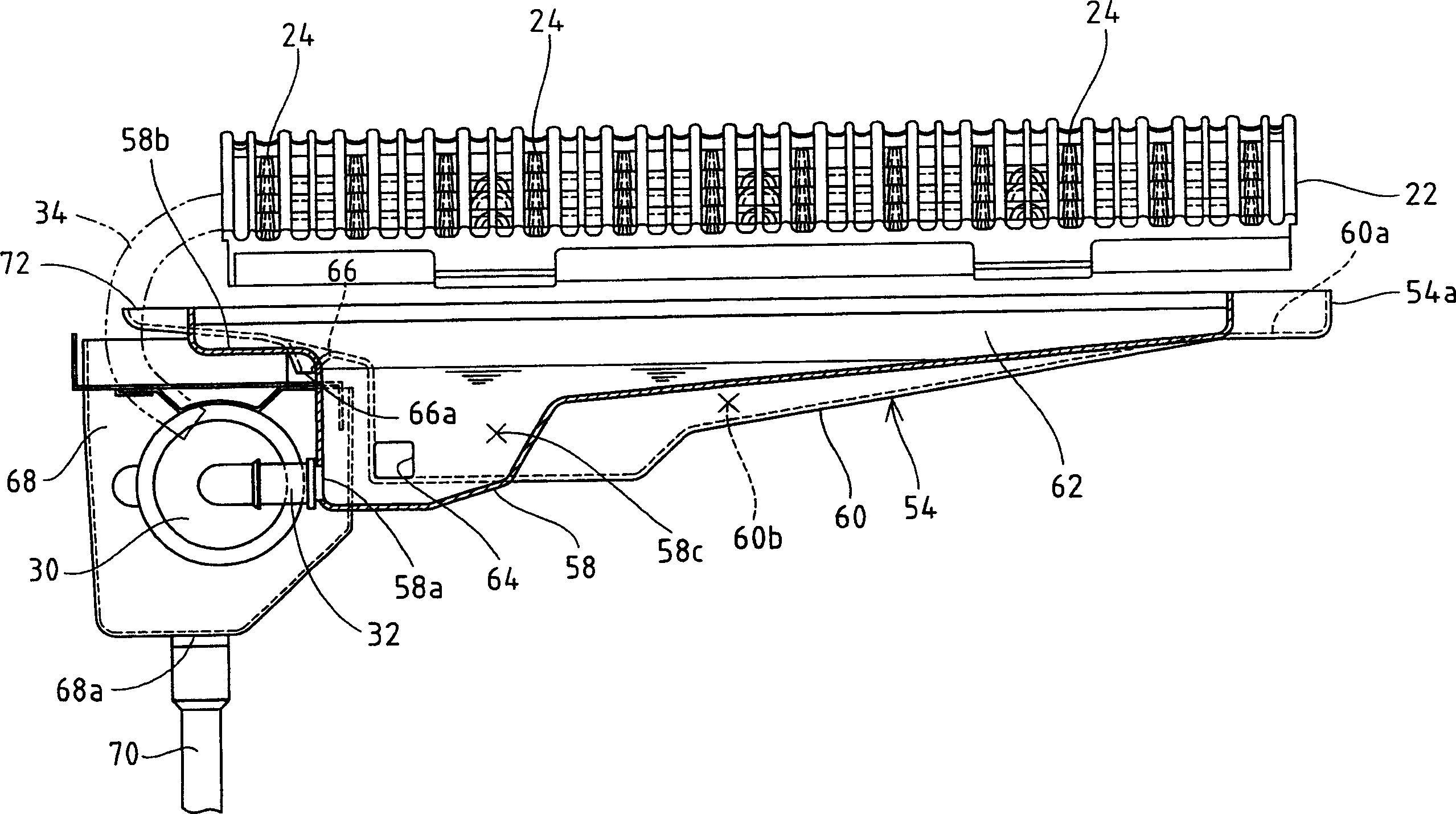

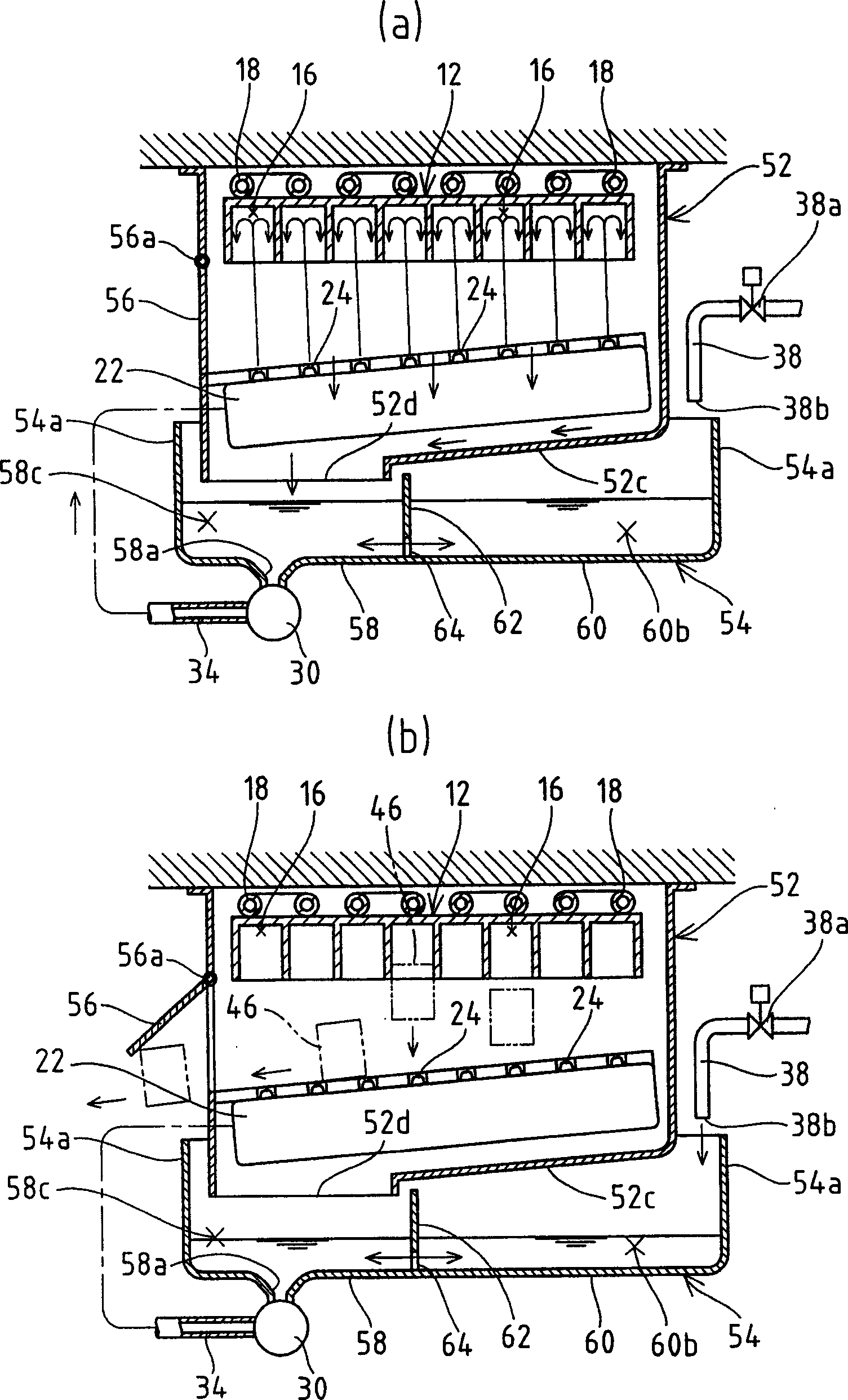

[0028] As shown in Figure 1, the ice-making mechanism 50 of embodiment 1 comprises: an ice-making chamber (ice-making part) 12, and this ice-making chamber 12 is made up of a large amount of ice-making chambers 16, and this ice-making chamber 16 is installed in box-shaped Near the top of the machine base 52 so as to open downwards; a water tray 22 with a plurality of water injection holes 24, the plurality of injection holes are associated with each ice making chamber 16 respectively; An ice-making water tank 54, which is used under storage conditions to store the required amount of ice-making water and to collect unfrozen water as described below. At the top of the ice-making chamber 12, the evaporating pipes 18 communicated with the refrigeration system (not shown) are arranged in close contact with each other and in a zigzag form to circulate the refrigerant during the ice-making operation and thus force the above-mentioned ice-making chamber 16 cool down....

Embodiment 2

[0048] In Embodiment 1, the open unit type ice-making mechanism 50 is applied, and its ice-making water tank 54 is internally divided into a circulation tank part 58 and a storage tank part 60, and it has a guide plate (guide device) 52c, which guide plate It is used to guide the unfrozen water in the ice making chamber (ice making part) 12 only to the circulation tank portion 58 . However, for Figure 5-9 In the illustrated second embodiment, a closed unit type ice making mechanism 80 is described, the ice making water tank 82 is internally divided into a circulation tank part 84 and a storage tank part 86, and it has a guide plate (guide means ) 90, the guide plate is used to guide the unfrozen water in the ice making compartment (ice making part) 12 only to the circulation tank portion 84. The basic structure and reference of the ice making mechanism 80 of Embodiment 2 Figure 10 The structure of the closed cell type ice making mechanism 10 described is substantially the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com