Photo etching alignment mark in use for X-ray

A lithography alignment and X-ray technology, applied in the field of X-ray lithography alignment marks, can solve problems such as difficult guarantee, deformation, high system accuracy, etc., and achieve the effect of improving alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

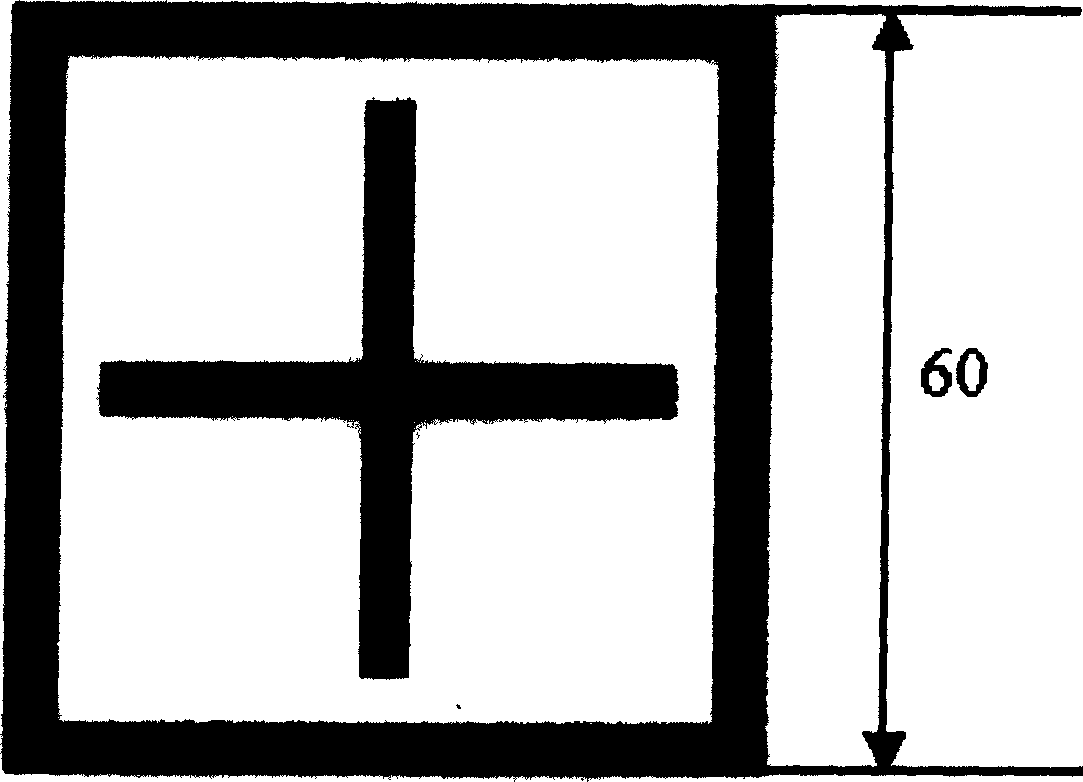

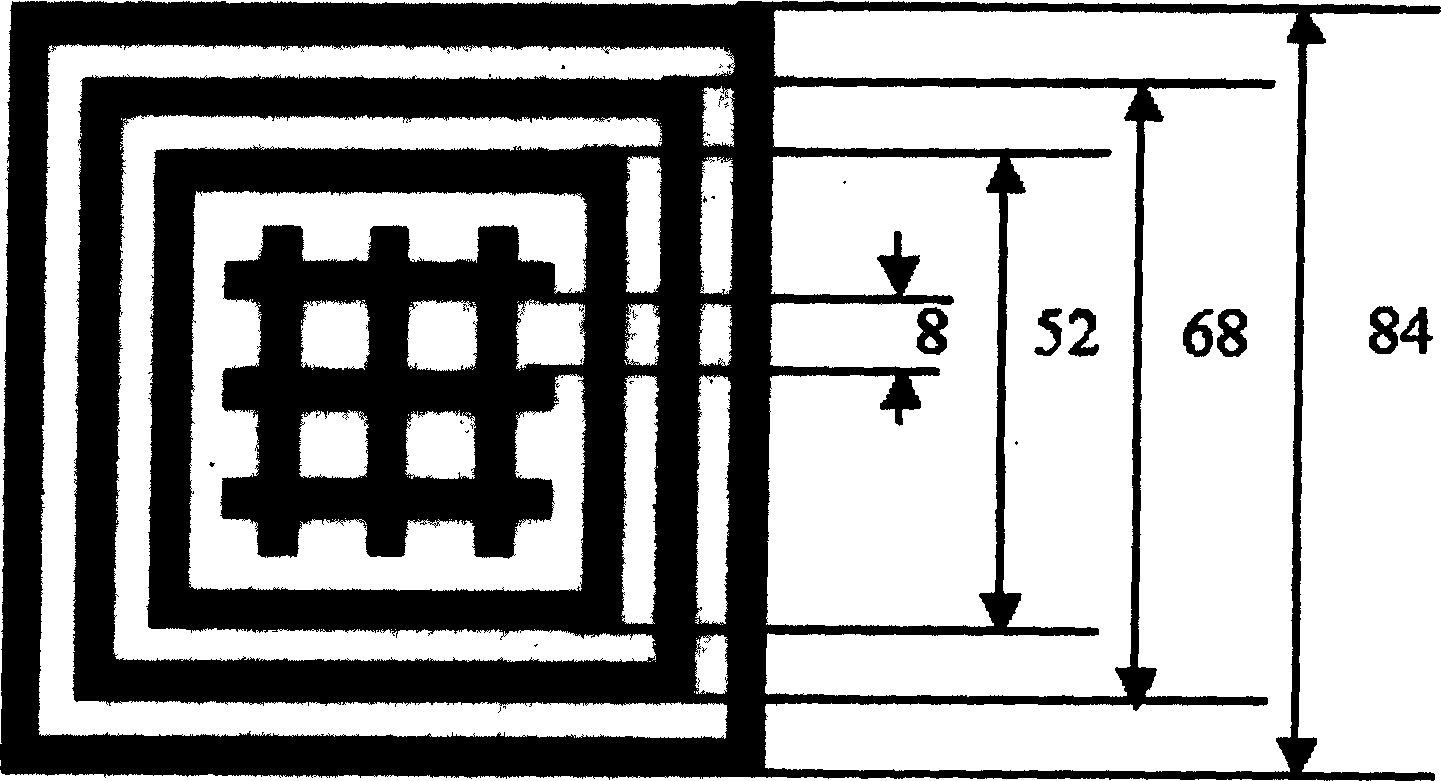

[0014] The alignment mark of the present invention consists of two parts, including three square marks on the mask and six straight line marks on the silicon wafer. The advantages of the new invention will be described below by comparison.

[0015] For the original alignment marks a box and a cross such as figure 1 As shown, it is assumed that the central coordinates of the left and right cross marks on the silicon chip recognized by the computer after image processing are (X W1 , Y W1 ), (X W2 , Y W2 ), the center coordinates of the coordinate box mark on the mask are (X M1 , Y M1 ), (X M2 , Y M2 ), then the values of ΔX (offset in X direction) and ΔY (offset in Y direction) can be expressed by the following formula:

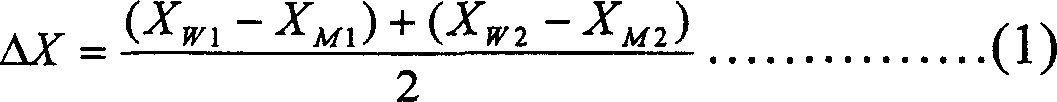

[0016] ΔX = ( X W 1 - X ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com