Online optimized method for blending oil products, and system of implementing the method

A blending and oil technology, applied in control/regulating system, general control system, chemical variable control, etc., can solve the problems of maintaining the quality of blended product oil, analysis data error, influence of near-infrared light transmittance, etc. Achieve the effect of improving production efficiency and economic benefits, improving the level of intelligence, and maintaining normal, stable and effective operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

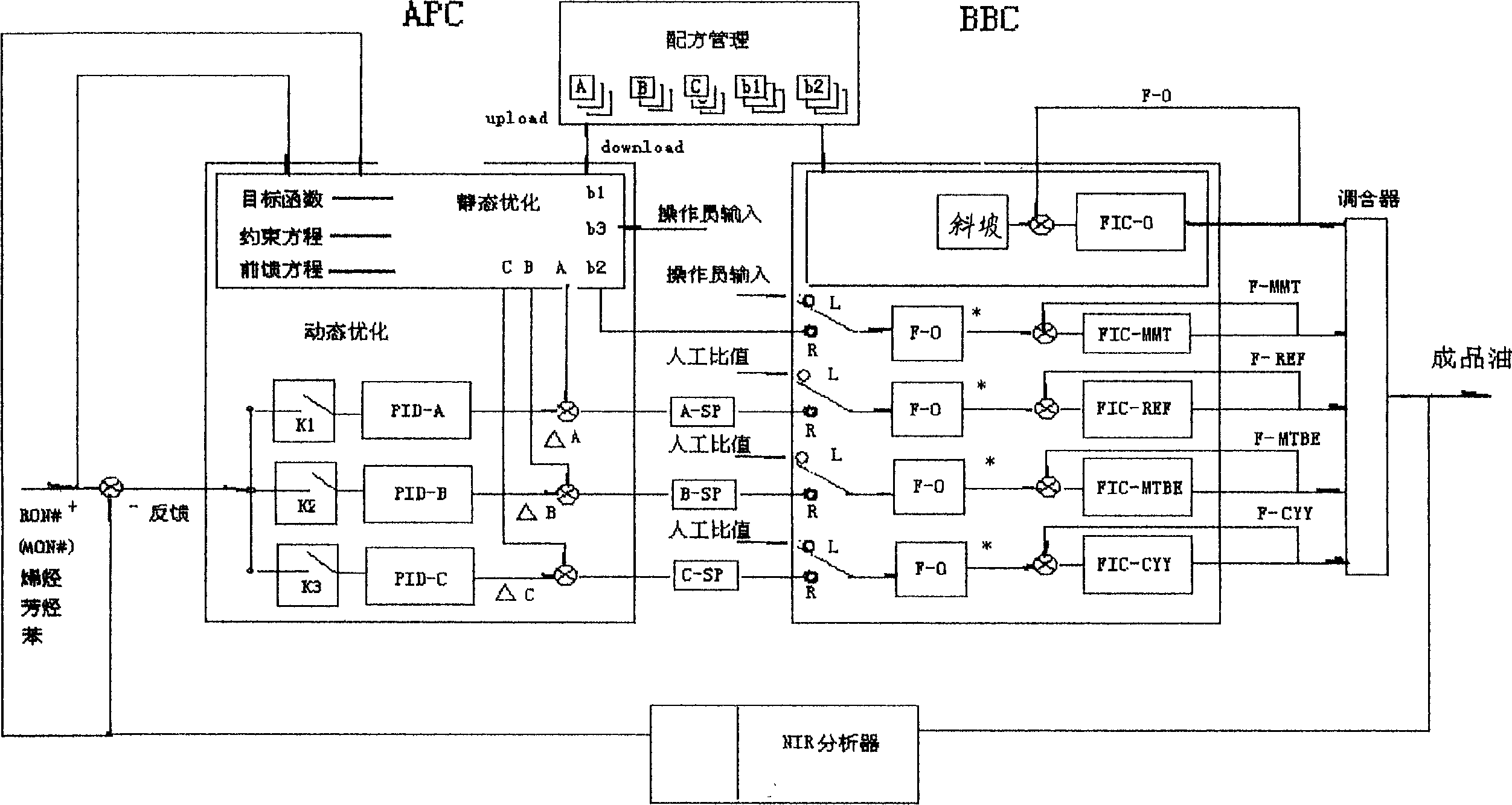

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

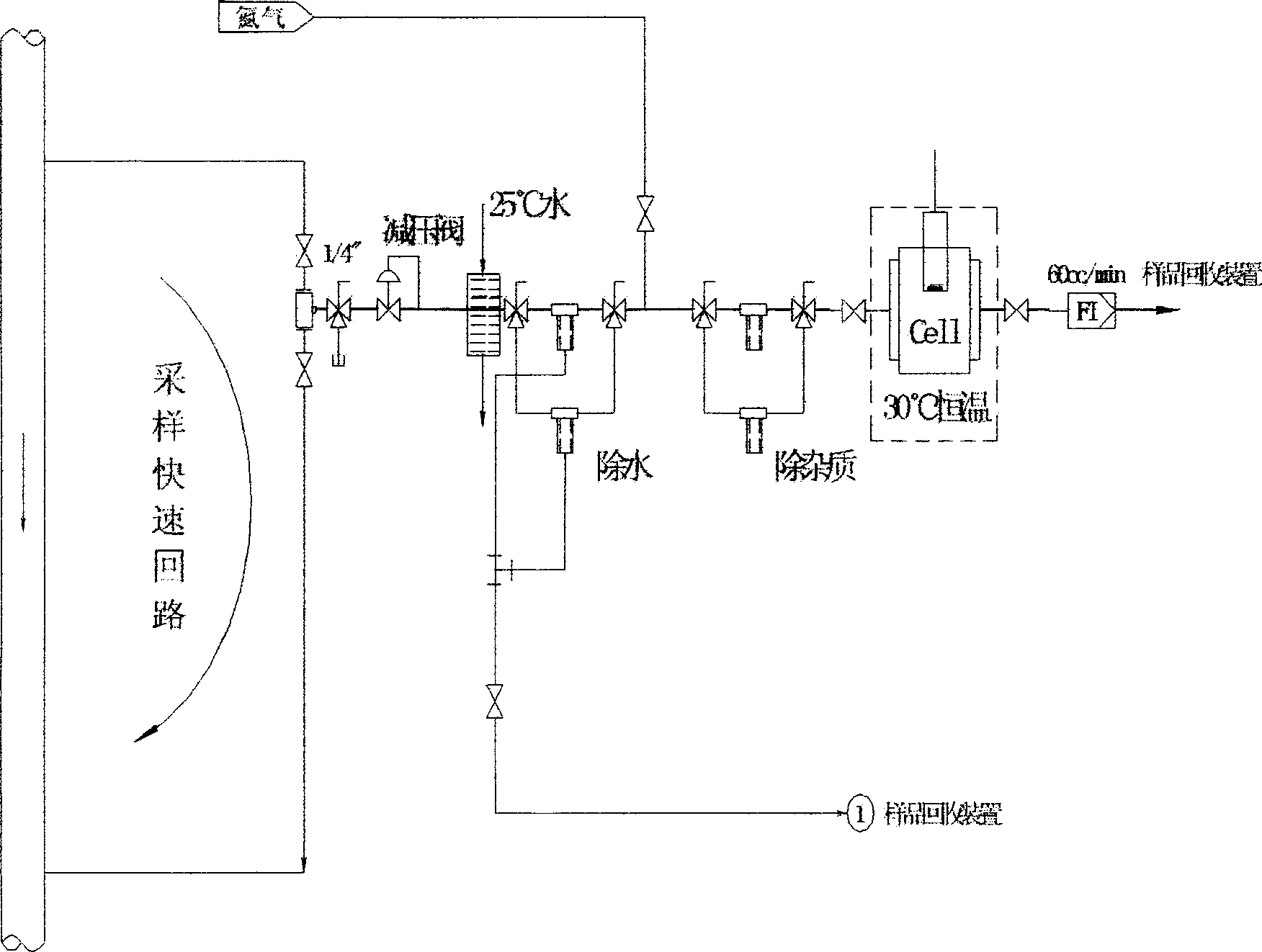

[0027] Such as figure 1 As shown, the sample passes through the sample fast loop from the component loop, and is split from the fast loop to the pretreatment system.

[0028] After the sample flows into the pretreatment system, it passes through the pressure reducing valve to reduce the pressure of the oil sample for the safe use of the pretreatment system.

[0029] The first constant temperature in the constant temperature device uses a water area. After the sample pipeline passes through this water area, it can fully perform heat exchange, so that the sample temperature can basically reach a certain value, so that the secondary constant temperature device can quickly make the sample reach the predetermined temperature. After constant temperature, the stability and accuracy of the sample analysis results are improved. The effect of constant temperature can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com