On-line solid phase micro-extraction method in capillary column and apparatus therefor

A technology of solid-phase microextraction column and extraction device, which is applied in the field of extraction, can solve the problems of high analysis cost of extraction stationary phase, high analysis cost, difficulty in ensuring the repeatability of analysis results, and unsatisfactory extraction and enrichment multiples, so as to achieve operability And the effect of improved stability, convenient installation and replacement, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

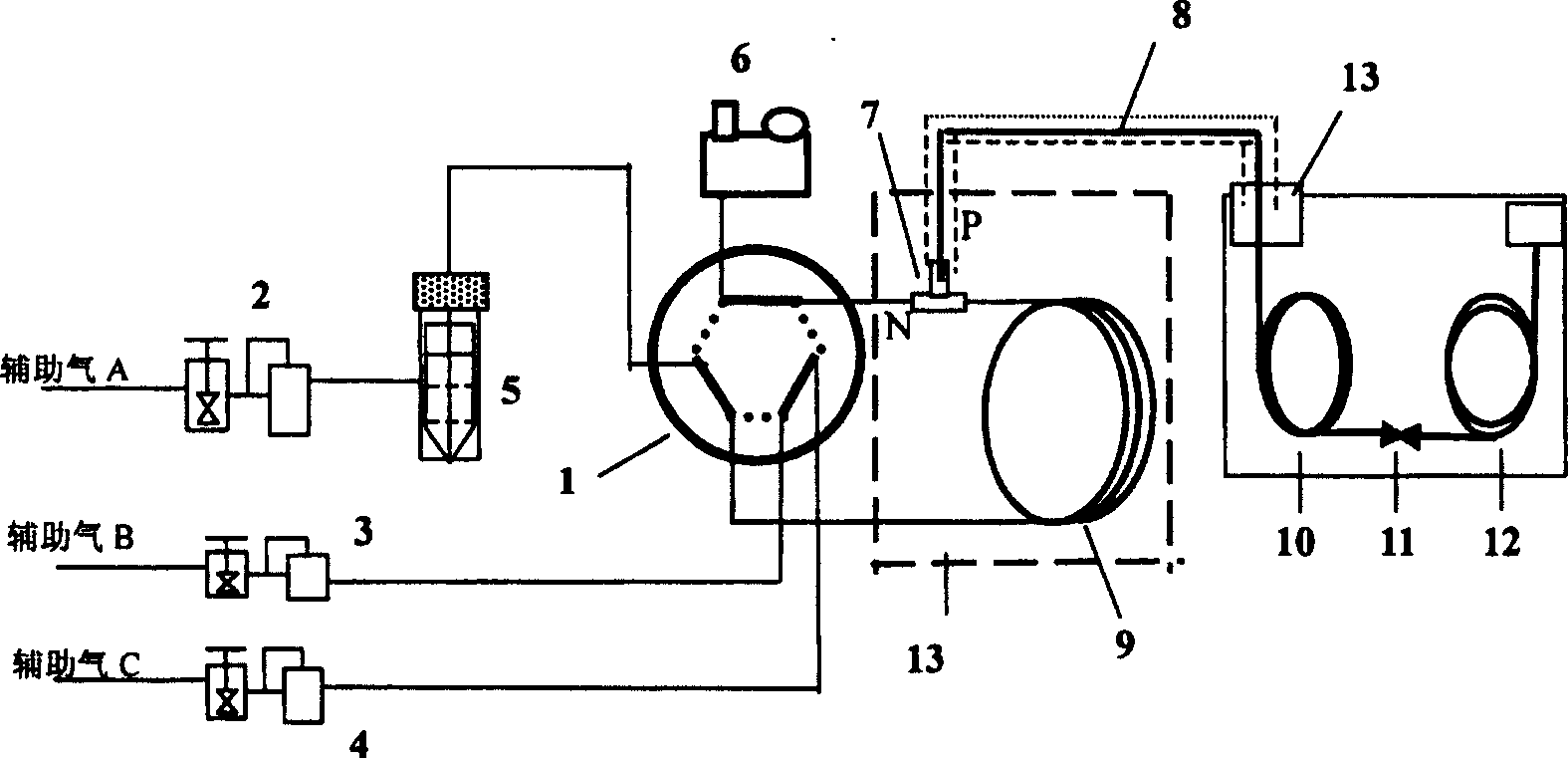

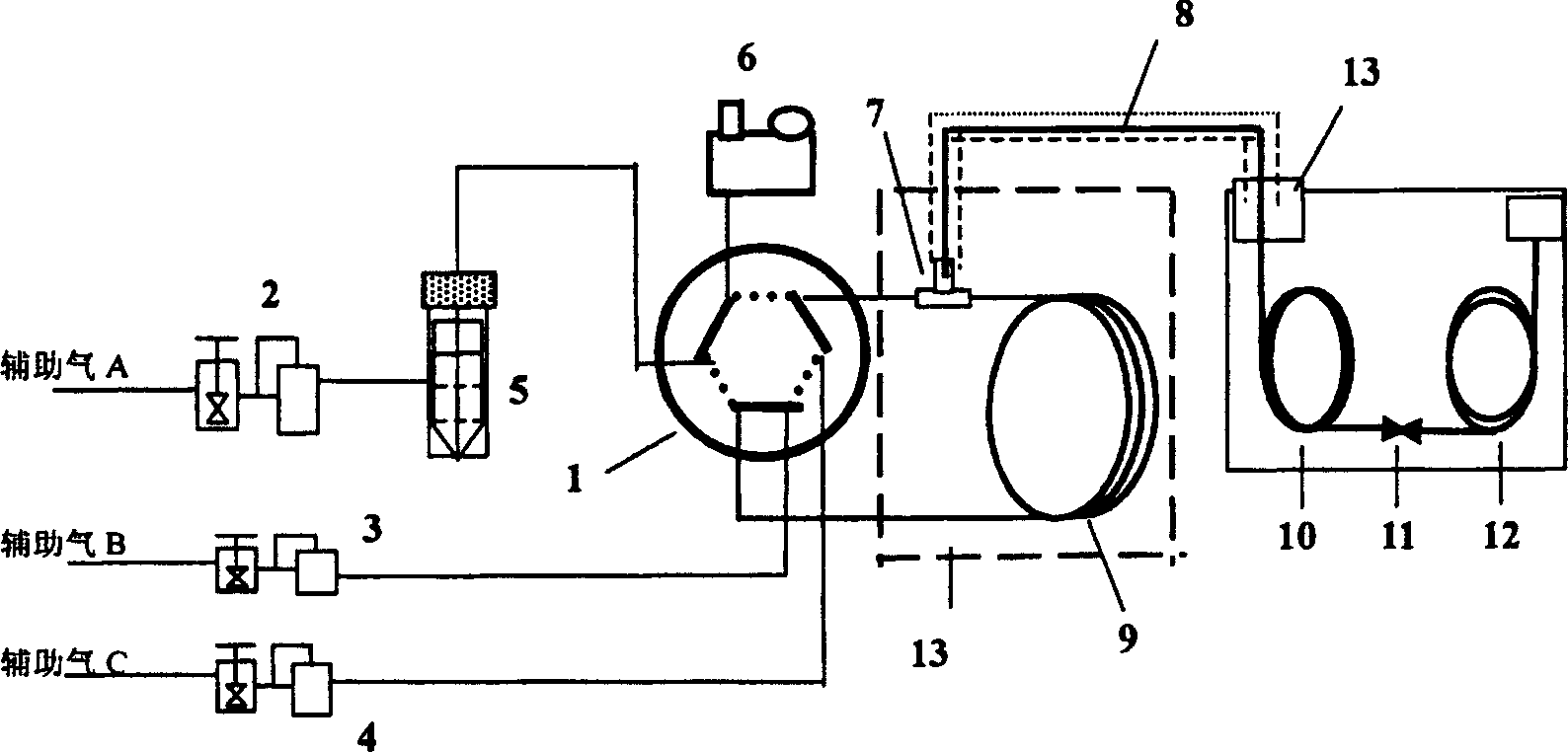

[0038] The parameters of the sample pretreatment device for extracting and enriching organic hydrocarbon pollutants in drinking water and surface water using the device and method of the present invention are as follows:

[0039] The capillary solid-phase microextraction column (9) is a 5M×0.53mm inner diameter×1.2μm film thickness OV-1 elastic quartz capillary column; the desorption temperature is 240°C; the transfer tube (8) uses a 1.2M×120μm inner diameter elastic quartz capillary, and The temperature of the heating tube is 220°C.

[0040] 15mL water sample with a concentration of 10μg / L nC 12 ~nC 19 , the dynamic extraction time is 2.5 minutes, analyzed by Agilent 6890-Plus gas chromatograph, the analysis spectrum obtained is as follows Figure 2A ; while the same sample (containing 10 μg / L nC 12 ~nC 19 ), and the extraction time is 35 minutes, the result is as spectrum Figure 2B . In addition, the same sample (10 μg / L nC in 15 mL of water) was tested in a short tim...

Embodiment 2

[0043] The device and method of the invention are used to extract and enrich organic pollutants such as trace polycyclic aromatic hydrocarbons in water, the sample volume is 300mL, and the concentration of organic components is 0.2-2 μg / L. The desorption temperature of the extraction column (9) is 310° C., and other conditions are the same as in Example 1. Its analytical spectrum is as image 3 .

Embodiment 3

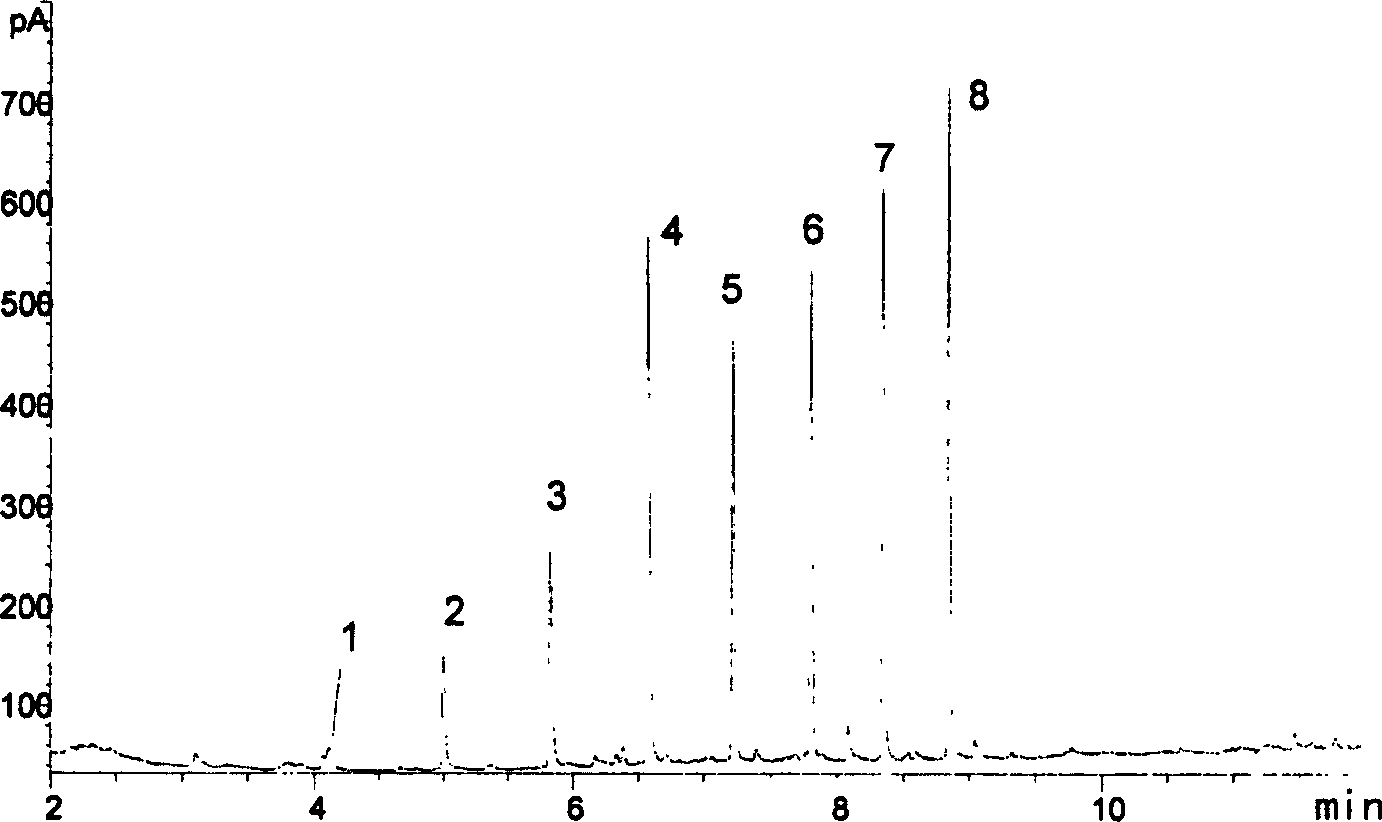

[0045] The device and method of the invention are used to extract the residual components of organochlorine pesticides in water. The sample volume is 30mL, the concentration of pesticide residues is ~0.25μg / L, and the extraction time is 5 minutes. The desorption temperature of the extraction column (9) is 290° C., the gas chromatographic detector is an electron capture detector, and other conditions are the same as in Example 1. Its analytical spectrum is as Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com