Heat conductive cubic boron nitride grinding wheel and its preparation process

A cubic boron nitride and preparation technology, which is applied in the direction of manufacturing tools, bonded grinding wheels, and other chemical processes, can solve the problems of scrapped parts, workpiece burns, and insufficient heat to achieve improved thermal conductivity, excellent wear resistance, and Overcoming the effects of grinding burn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

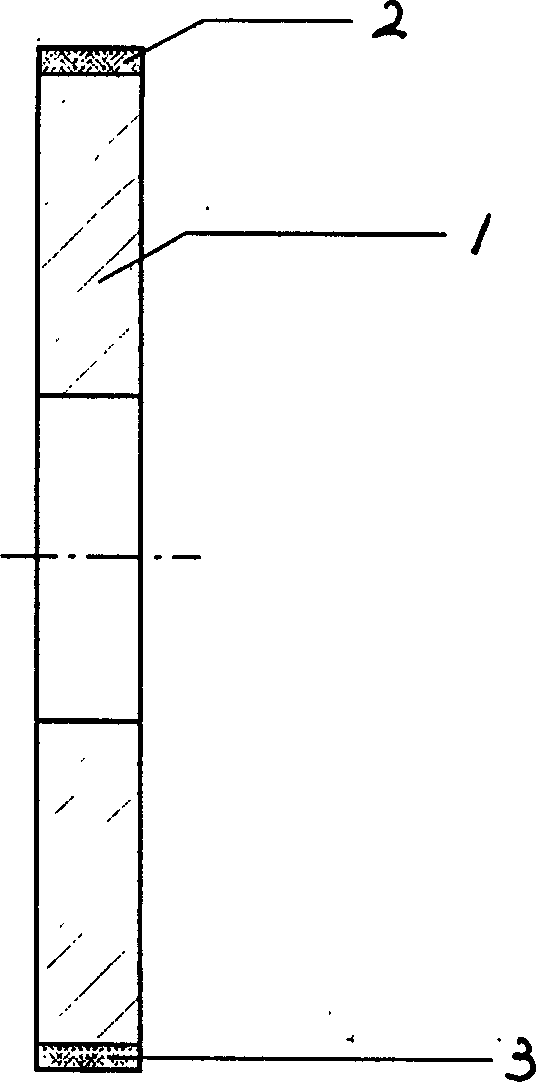

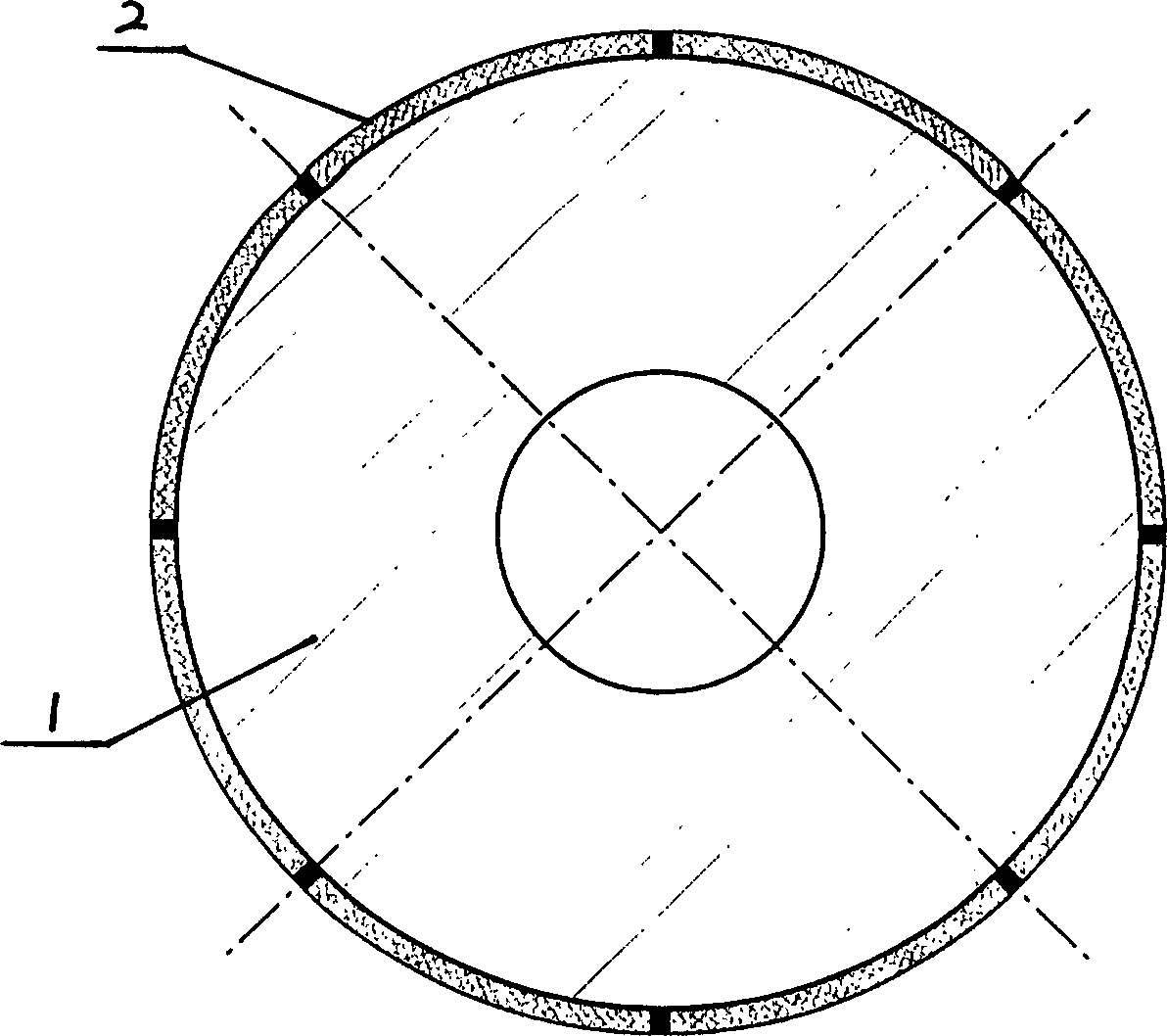

[0009] Such as figure 1 , 2 As shown, an aluminum alloy substrate 1 is included, and a thermally conductive cubic boron nitride abrasive layer 2 containing copper and chromium alloy particles 3 is arranged on the aluminum alloy substrate. The abrasive layer is composed of cubic boron nitride, copper, chromium alloy particles and adhesive Binder composition.

[0010] The volume percentage of each raw material of the heat-conducting cubic boron nitride abrasive layer containing copper and chromium alloy particles is 90% of cubic boron nitride, 8% of copper and chromium alloy particles, and 2% of binder, of which copper and chromium alloy particles The volume is 1:1.

[0011] A preparation process for a heat-conducting cubic boron nitride grinding wheel. First, a heat-conducting cubic boron nitride abrasive layer containing copper and chromium alloy particles is produced: use cubic boron nitride as the abrasive and add vitrified bond, copper and chromium alloy particles, and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com