Sound absorbing board and production thereof

A sound-absorbing panel and panel body technology, which is applied in the direction of sound insulation, manufacturing tools, building components, etc., can solve the problems of difficult installation and fixation, poor appearance color, rough texture, etc., and achieve the effect of good sound absorption effect and bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

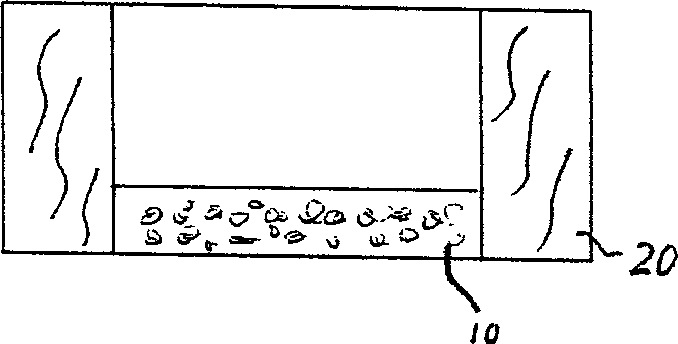

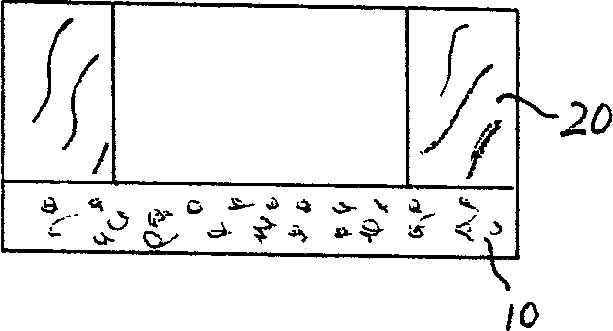

[0018] Such as figure 1 , 2 As shown, the sound-absorbing panel provided by the present invention is made of resin, and the panel body 10 has a labyrinth-shaped through-hole structure. Since the sound-absorbing panel disclosed in the present invention has good overall strength, if the unit area of the panel body 10 is moderate, it can meet the installation requirements depending on its own strength. If the area is large, it can be considered to add reinforcement around the sound-absorbing panel The ribs 20 and the reinforcing ribs 20 are made of solid resin. The thickness of the reinforcing ribs 20 around the sound-absorbing board is greater than or equal to the thickness of the board body 10 . The sound-absorbing board obtained by the invention has excellent sound-absorbing effect. The present invention has excellent performance, and th...

Embodiment 2

[0020] In order to simplify the preparation process and improve production efficiency, the present invention provides a method of pressurized injection molding, specifically injecting the resin raw material and curing agent into the mold through pressure gas.

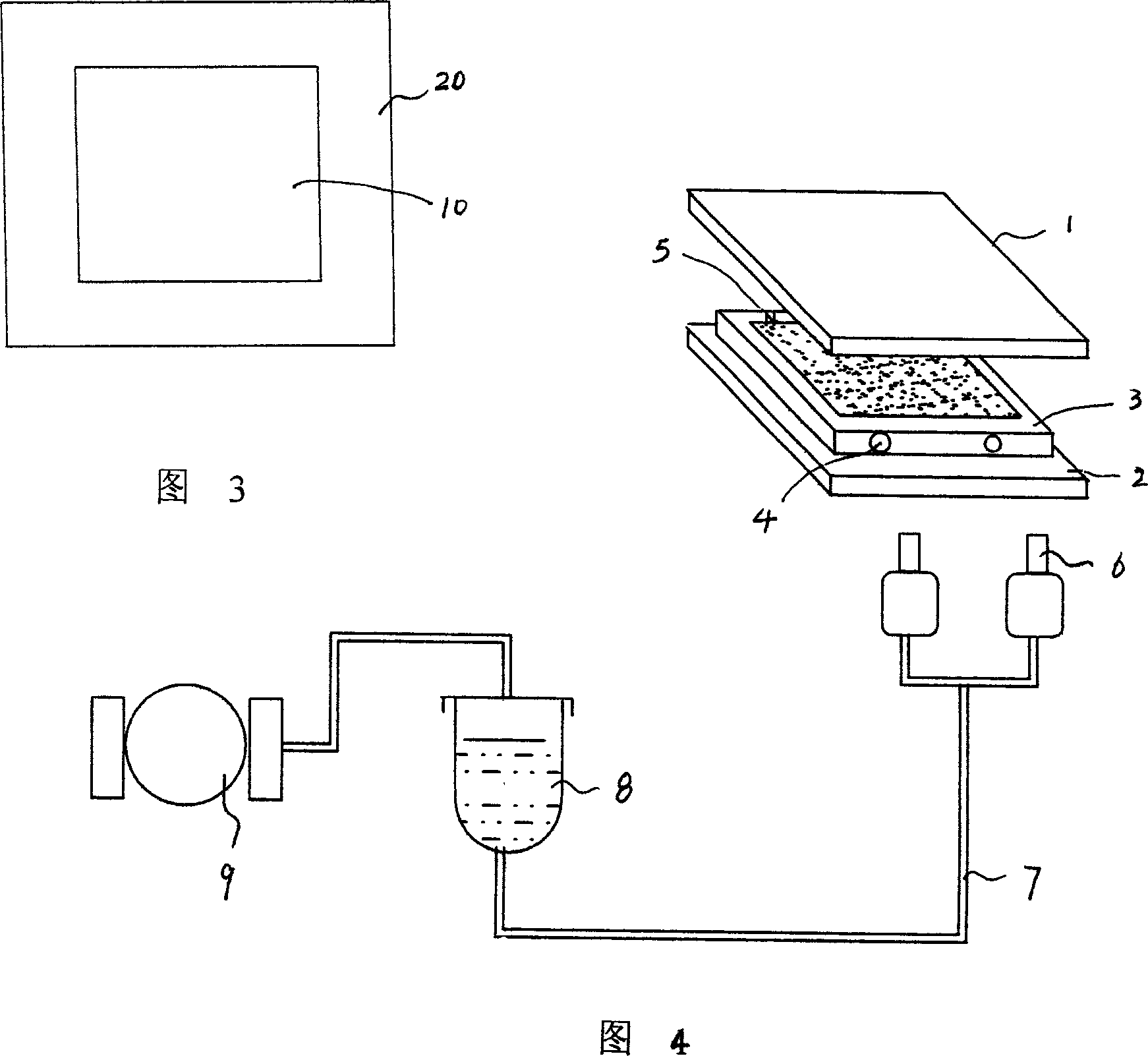

[0021] Referring to Fig. 4, described mold 3 is the frame body of closed ring shape, and the shape of mold can be square, rhombus etc. and is convenient to splicing into the geometrical shape of large surface, and its upper and lower end has upper and lower sealing plate 1,2, described The particle skeleton is placed in the mold 3, and the injection hole 5 and the exhaust hole 6 are opened on the mold 3. The upper part of the material storage tank 9 has an air inlet connected to the pressure gas source, and the lower part of the material storage tank 9 has a discharge hole and a material injection duct. 8 is connected with the injection joint 7, and the injection joint 7 is connected with the aforementioned injection hol...

Embodiment 3

[0023] Taking epoxy resin as an example to illustrate the specific content of the preparation method.

[0024] In the present invention, industrial salt is selected as the soluble granule auxiliary material, which is sieved and classified after drying, and is divided into several particle grades from 80 mesh particles to 12 mesh particles, so as to obtain a particle prefabricated skeleton with uniform particle size. (When the thickness of the sound-absorbing board and the compaction density of the particle skeleton are the same, the peaks of the sound-absorbing coefficient curves of the sound-absorbing panels made of different mesh particle size skeletons are different.) Put the particle skeleton into the prepared mold for compaction. The compacted density is not less than 0.9 g / cm 3 , and preheat to about 70--80C.

[0025] Preheat 50% of unsaturated polyester or epoxy resin raw material and 50% curing agent polyamide respectively to about 60--70C to make it have good fluidit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com