Portable checking and information optimizing decisioning systme for rotary furnace maintenance

A portable detection and health maintenance technology, applied to drum furnaces, furnaces, lighting and heating equipment, etc., can solve problems such as uneven load distribution, low measurement accuracy, and large system errors, and achieve reliable information optimization and decision-making. Compact, full-featured effects analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

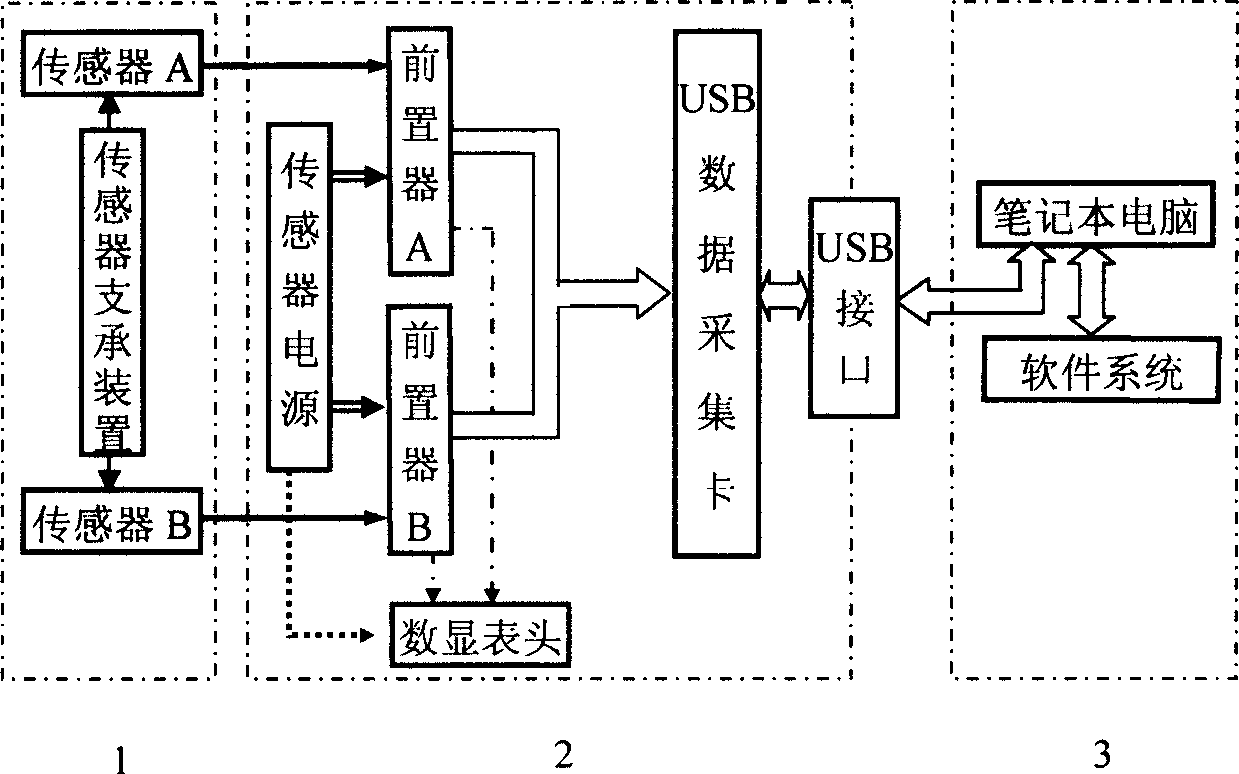

[0037] Refer to the accompanying drawings, a portable detection and information optimization decision-making system for the health maintenance of a rotary kiln. The system includes a sensor support device 1, an integrated signal acquisition device 2 and a portable computer device 3 that must not be electrically connected to each other. The system structure frame diagram is attached figure 1 Shown.

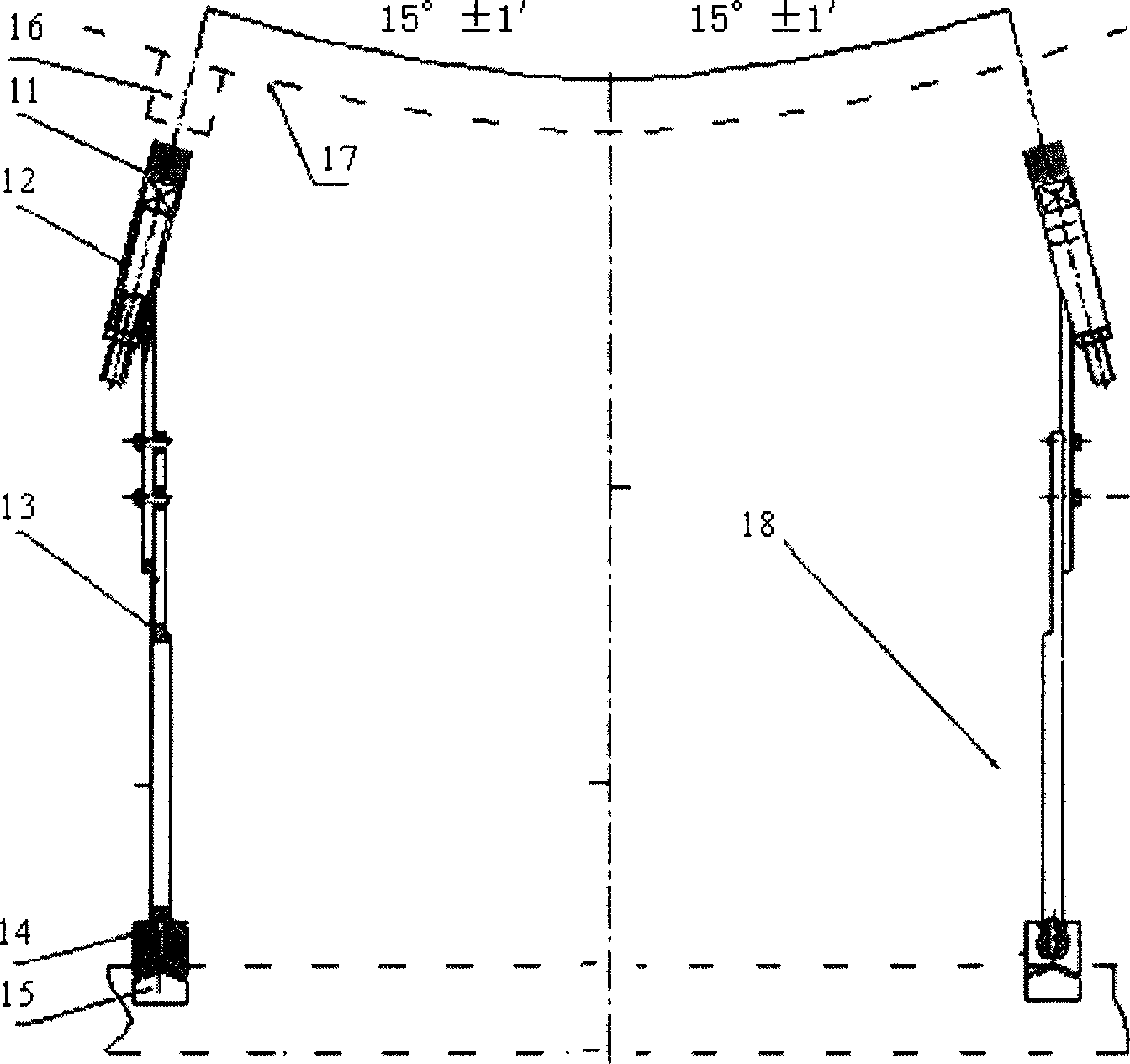

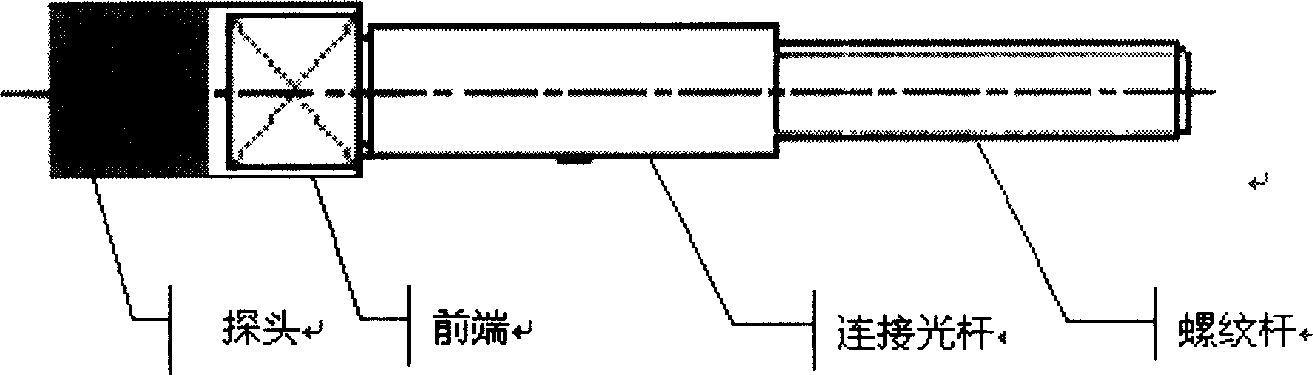

[0038] Attached figure 2 Shown is a schematic diagram of the installation structure of the sensor support device 1 of the present invention, including a movable support 18, an eddy current displacement sensor 11 and the corresponding eddy current displacement sensor A, B11 is provided with an eddy current displacement signal sensor key 16, a positioning support base 15. . The movable bracket 18 is composed of a sleeve 12, a connecting rod 13, and a magnetic suction seat 14. The eddy current displacement signal sensor key 16 is a rectangular square key, and the length of the square ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com