Variable-visual-axis stereoscopic vision measurement system and method based on active visual distance

A technology of stereo vision measurement and measurement method, applied in radio wave measurement system, measurement device, photo interpretation and other directions, can solve the problems of limited adaptability, not considering the influence of imaging area, etc., to achieve flexible imaging mode and improve rapidity and reliability, the effect of compact system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

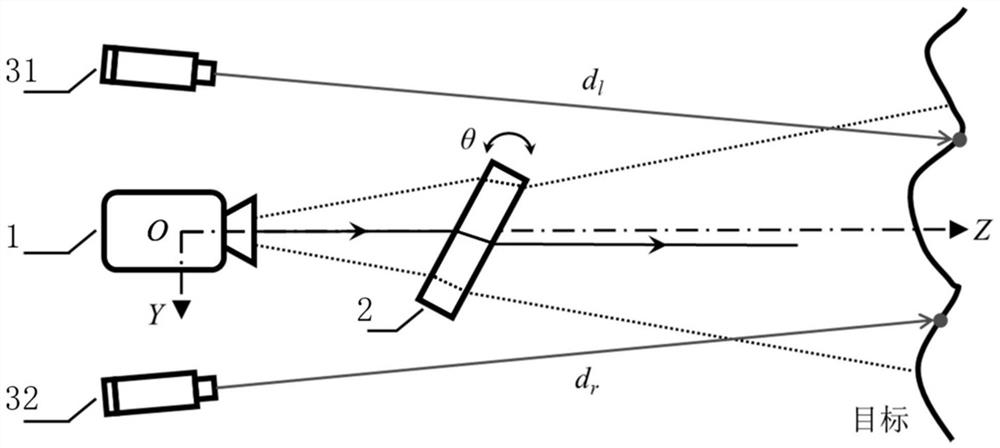

[0063] like figure 1 and figure 2 As shown, in this embodiment, a variable boresight stereo vision measurement system based on active viewing distance is proposed, which includes a camera 1, a yaw flat panel device 2 and a laser distance measuring device.

[0064] Camera 1 includes an image sensor and an optical lens. The target surface size and pixel resolution of the image sensor, the focal length of the lens, and the depth of field and other parameters are determined by the size and distance of the target to be measured. The detection band of the image sensor is determined by the physical properties of the target to be measured. , is the visible light band or the infrared light band.

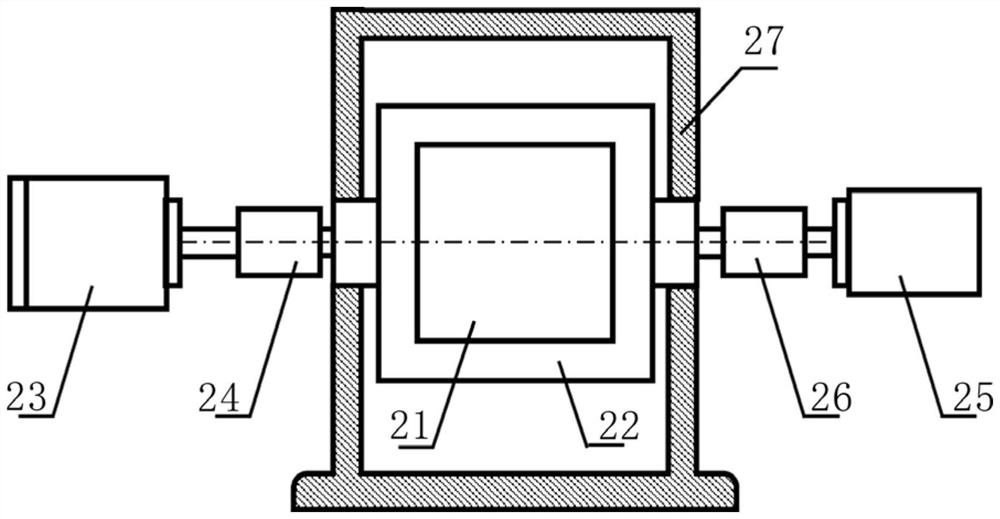

[0065] The yaw plate device 2 includes a transparent plane plate 21 and a yaw drive mechanism. The plane plate 21 is made of transparent glass material and can perform reciprocating yaw motion around the X-axis direction. The parameters such as its size, thickness, and refractive index are ...

Embodiment 2

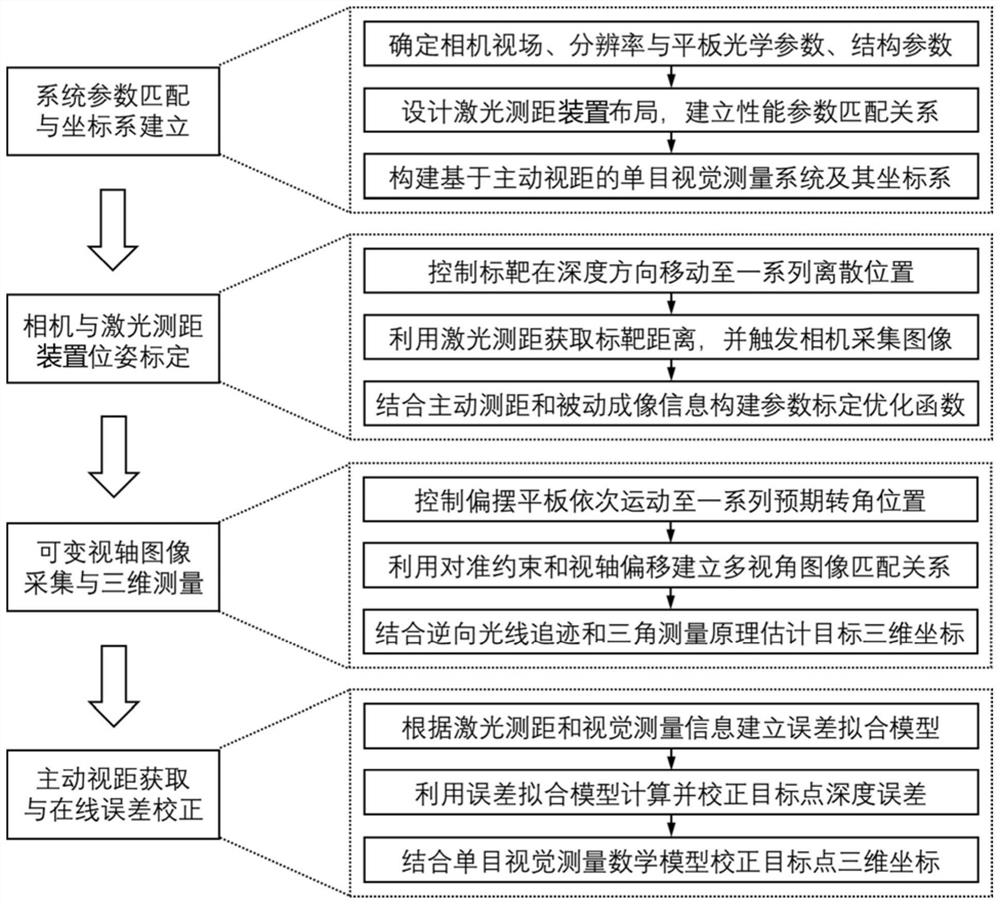

[0069] like Figure 3 ~ Figure 6 As shown, the present embodiment proposes a measurement method based on the active sight distance variable viewing axis stereo vision measurement system in the first embodiment, which specifically includes the following steps:

[0070] Step S1: System parameter matching and coordinate system establishment.

[0071] According to the measurement range and resolution requirements of the variable boresight stereo vision measurement system, determine the optical parameters and structural parameters of the camera 1, the yaw plate device 2, the first laser range finder 31 and the second laser range finder 32, according to Its relative pose relationship constructs a variable boresight stereo vision measurement system based on active sight distance, as well as the working coordinate system, camera coordinate system and laser rangefinder coordinate system of the measurement system.

[0072] The working coordinate system O-XYZ of the measurement system i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com