Large-view-field high-resolution laser scanning system based on piezoelectric motor adjustment

A piezoelectric motor, high-resolution technology, applied in the field of laser scanning, can solve problems such as difficult to achieve, increase the distortion and fracture of the MEMS galvanometer reflection surface, improve system resolution and scanning range, break through technical bottlenecks, reduce effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

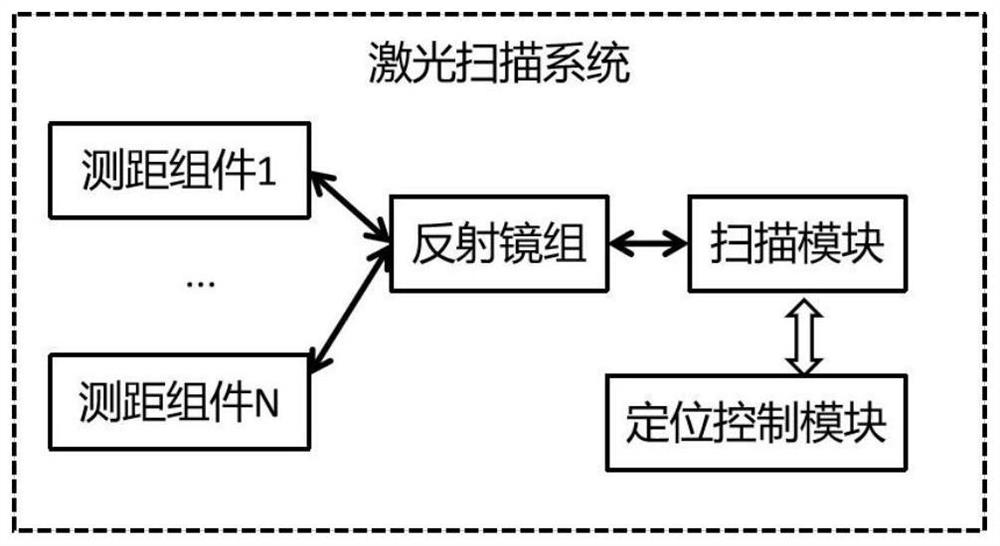

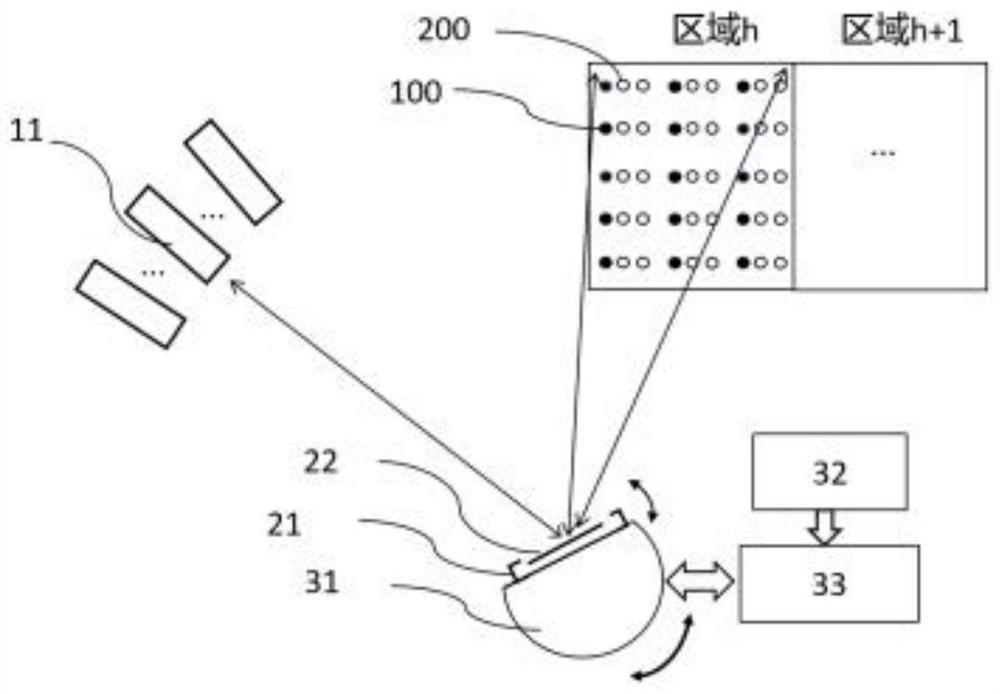

[0049] The large-field high-resolution laser scanning system based on piezoelectric motor adjustment in this embodiment includes: a ranging module composed of n ranging components, a mirror group and a scanning module; it is characterized in that a positioning control module is set in the system .

[0050] Ranging module for transmitting and receiving measurement laser beams to achieve distance measurement;

[0051] The mirror group is used to reflect the measurement beam emitted by each ranging component, and make it incident to the scanning module at a set angle;

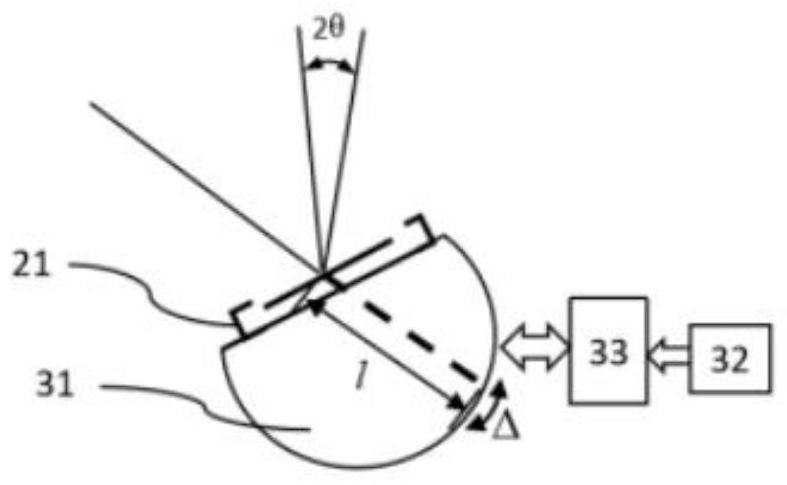

[0052] The scanning module, which is a two-dimensional MEMS galvanometer, is used to reflect the measuring beam to the space to be measured for two-dimensional scanning;

[0053] The positioning control module is composed of a piezoelectric motor, a driver and a positioning component; the two-dimensional MEMS galvanometer and the positioning component are fixedly installed, and the piezoelectric motor controls th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com