Flexible conductor, and apparatus and method for connecting a flexible conductor to a connection terminal

A technology of connecting terminals and flexible conductors, applied in the direction of conductive connection, connection, contact electrical connection, etc., can solve the problems of power limitation, inability to use, large size of flexible conductors and connecting terminals, etc., to avoid annealing problems and retain mechanical properties. , the effect of high mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

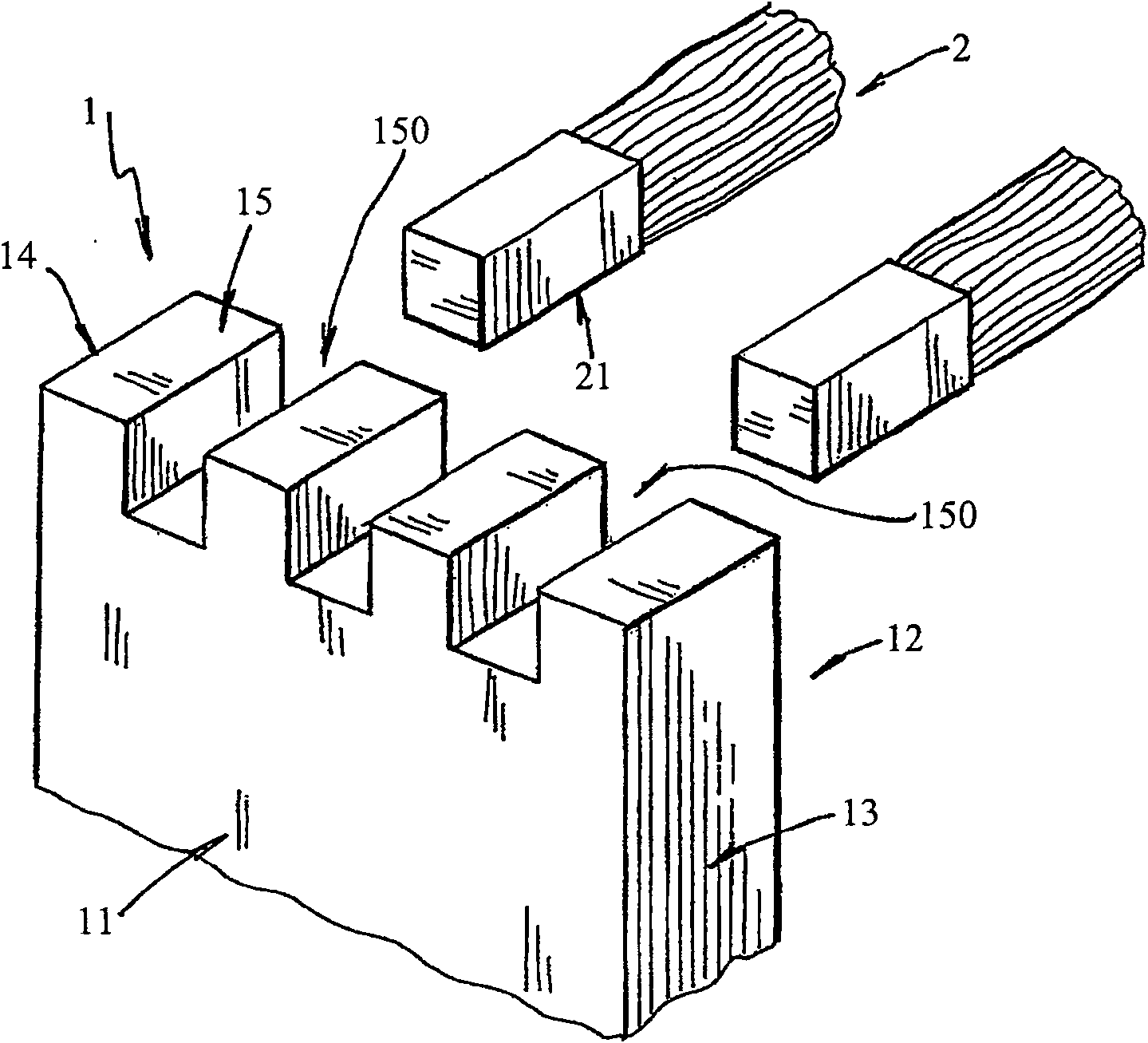

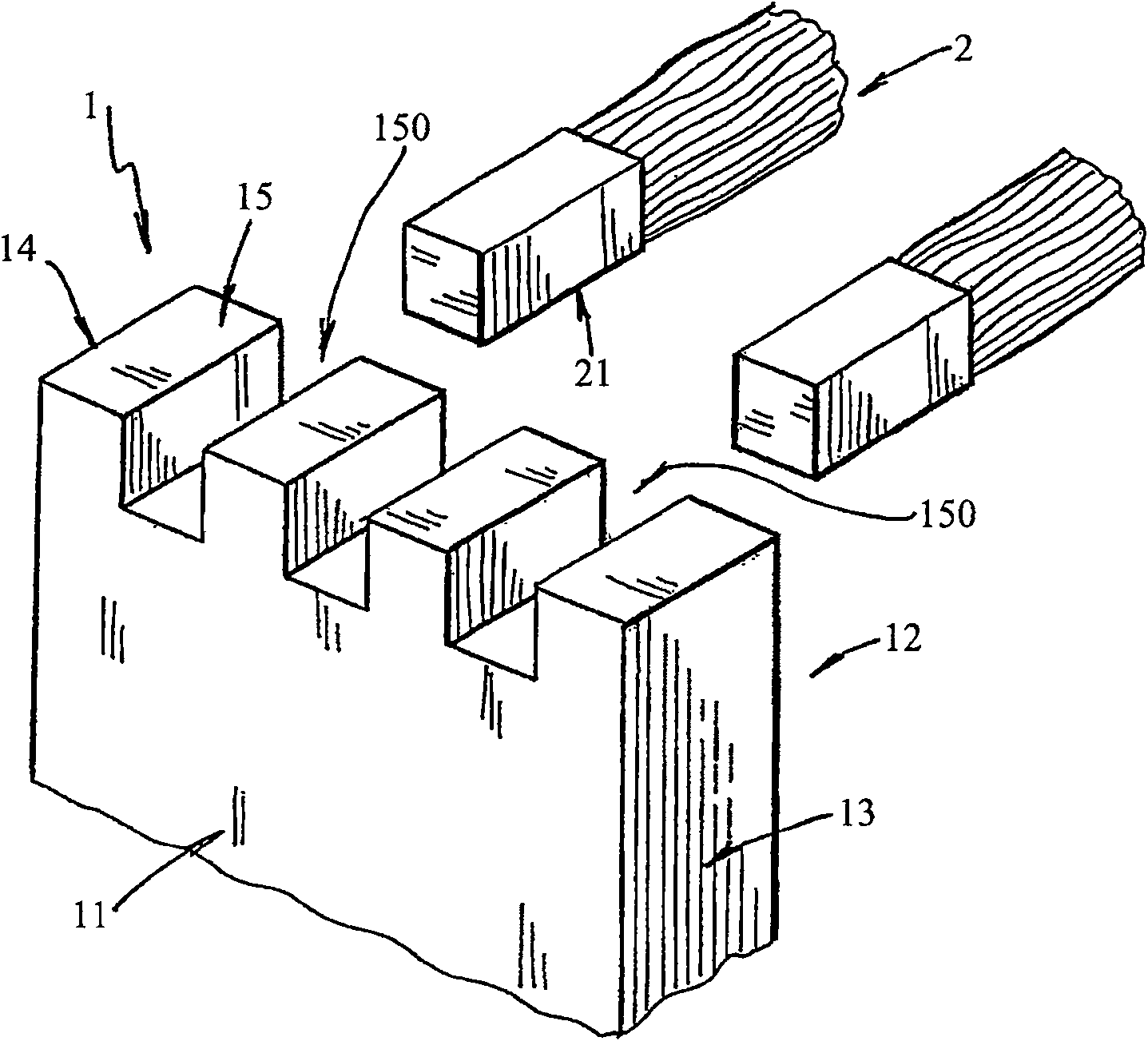

[0031] see figure 1 , The element constituting the connection means is the connection terminal 1 , which forms a substantially parallelepiped with an upper surface 11 and a lower surface 12 , two side surfaces 13 and 14 , and an end surface 15 . The connection terminal has one or more substantially parallelepiped-shaped grooves 150 on the end surface 15, which pass through the entire thickness of the connection terminal. Indeed in this example it can also be said that the profile of the end surface 15 is square-wave-shaped.

[0032] The second element constituting the connection means is a flexible conductor 2 having an end 21 whose shape substantially matches the inner wall of the groove 150 .

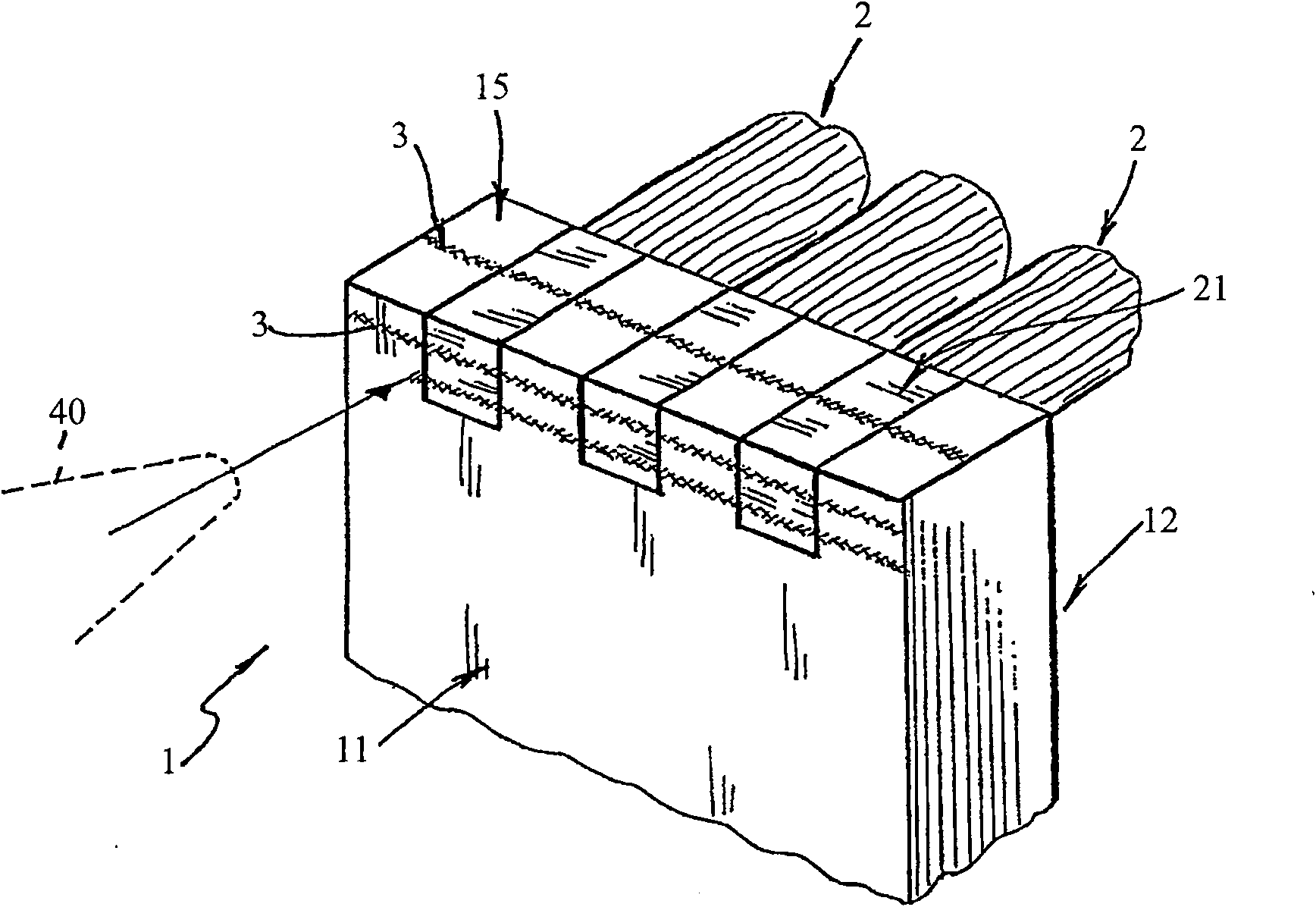

[0033] see figure 2 , shows that the connecting device according to the invention is constituted by the end 21 of the wire 2 which is inserted into said groove 150 . In this example the flexible conductor 2 protrudes from the lower surface 12 of the connection terminal 1 substanti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com