Processing method of ring kind part circumcircle and its device

A technology of rings and parts, applied in the field of outer circle machining of ring parts, can solve the problems of high risk, high investment, increase production cost, etc., and achieve the effect of small investment, high machining accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

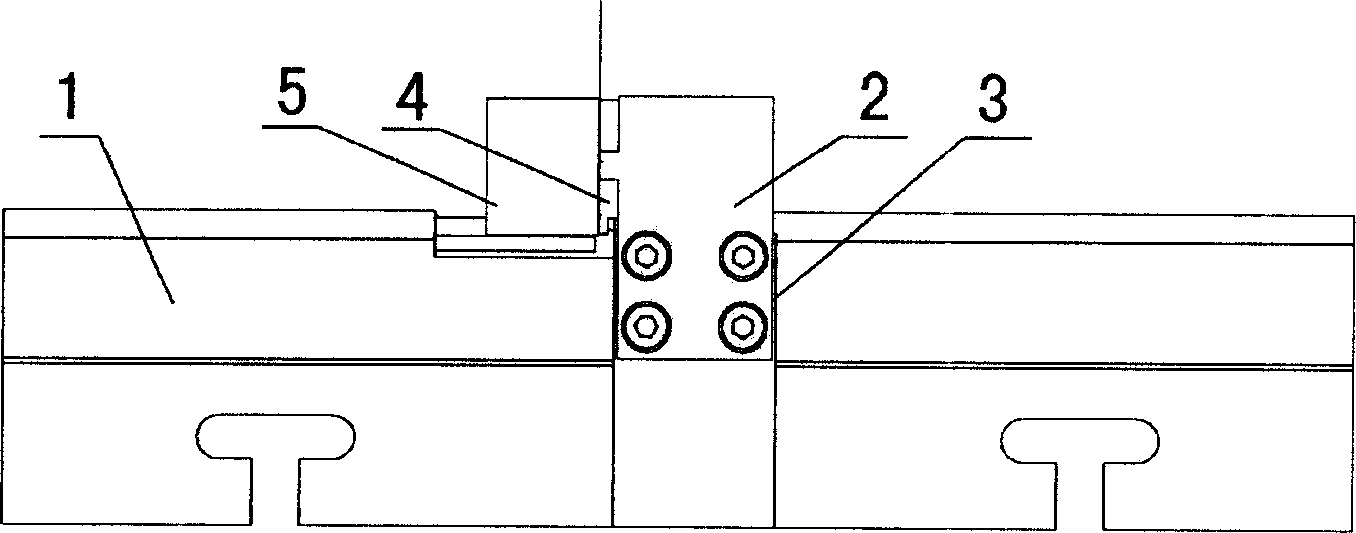

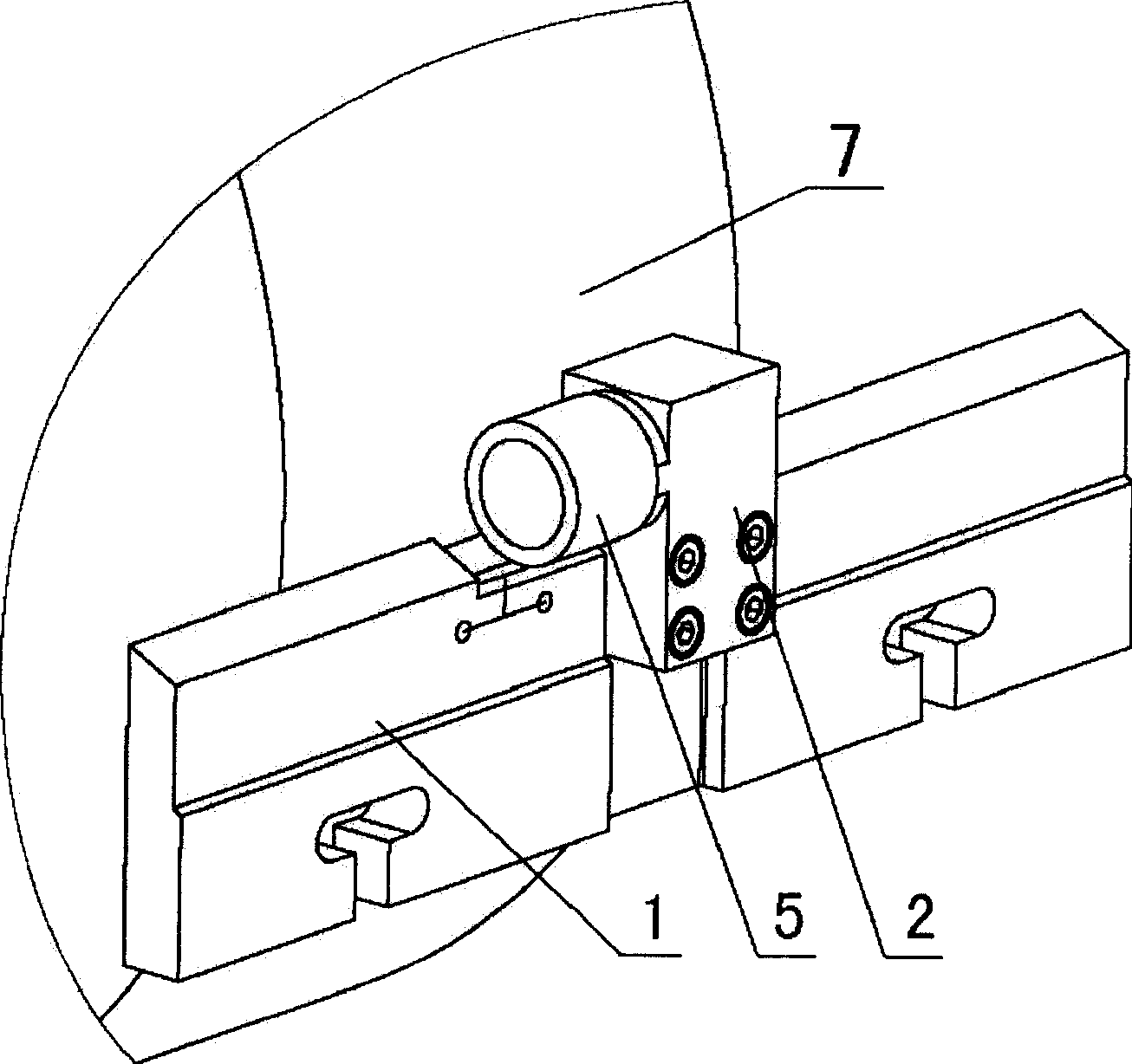

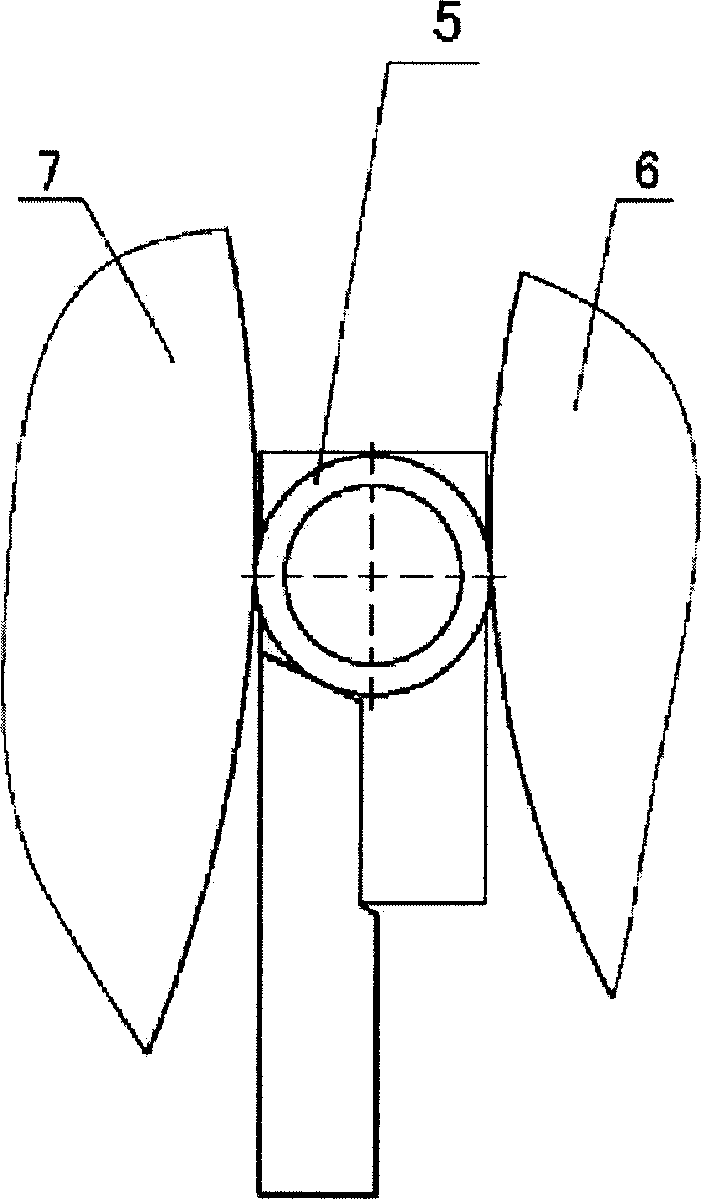

[0010] Embodiment of the present invention: a groove (3) is opened on the supporting plate (1), and the support surface of the supporting plate (1) in contact with the workpiece can be made into a slope or a horizontal plane. In order to make the stability more reliable during processing, it is better to place the The support surface of the supporting plate (1) in contact with the workpiece is made into a slope, the adjustable positioning block (2) is installed in the groove (3) through screws, and a ring positioning surface is made on the positioning block (2) (4), make the supporting surface of the supporting plate (1) perpendicular to the ring positioning surface (4) of the positioning block (2), and make the outer diameter of the ring positioning surface (4) smaller than the ring type parts to be processed (5) Outer circle diameter, make the inner circle diameter of the ring positioning surface (4) greater than the inner circle diameter of the ring type parts (5) to be proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com