Solar cell module

A technology of solar cells and components, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problem of water vapor output performance degradation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

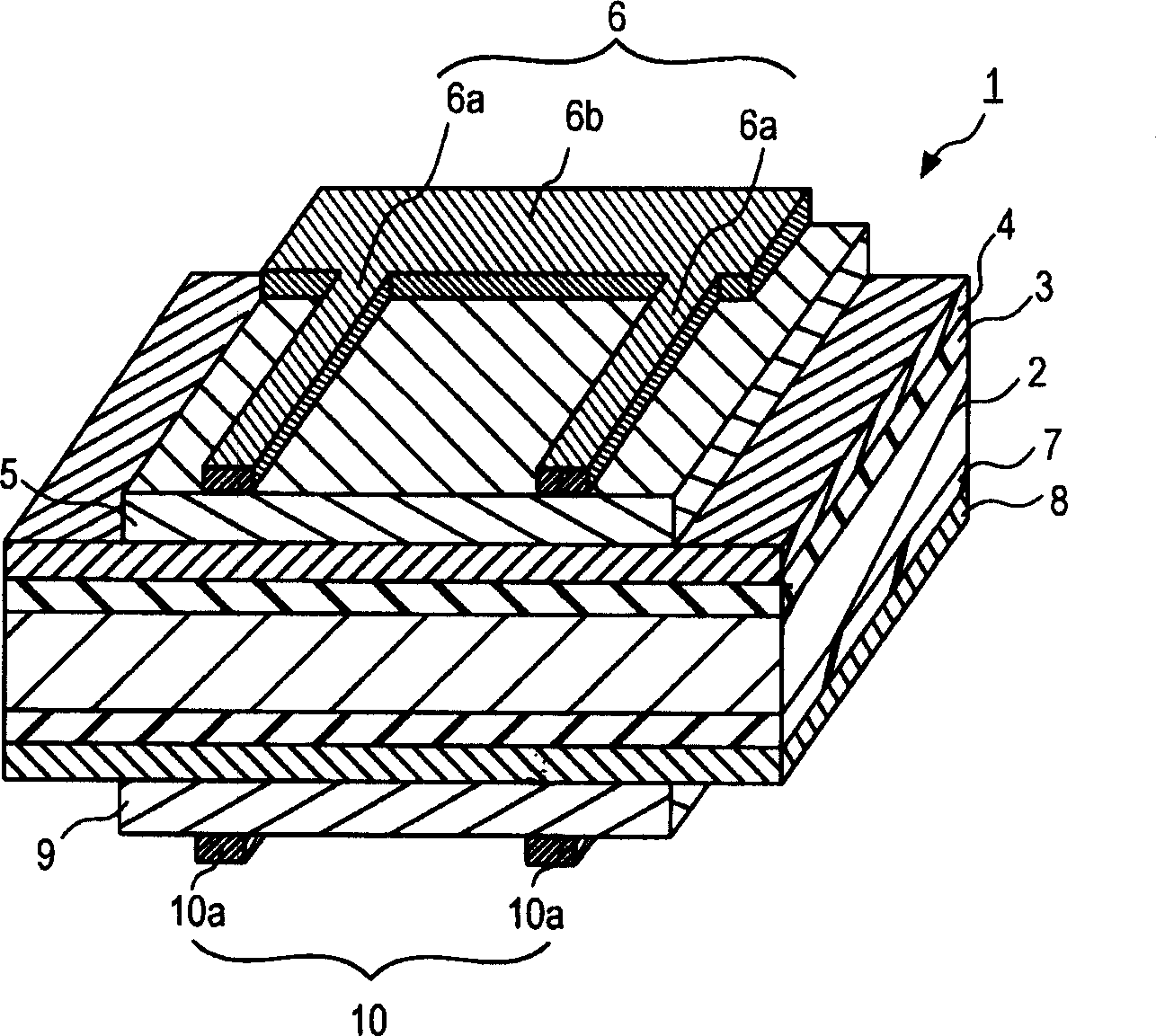

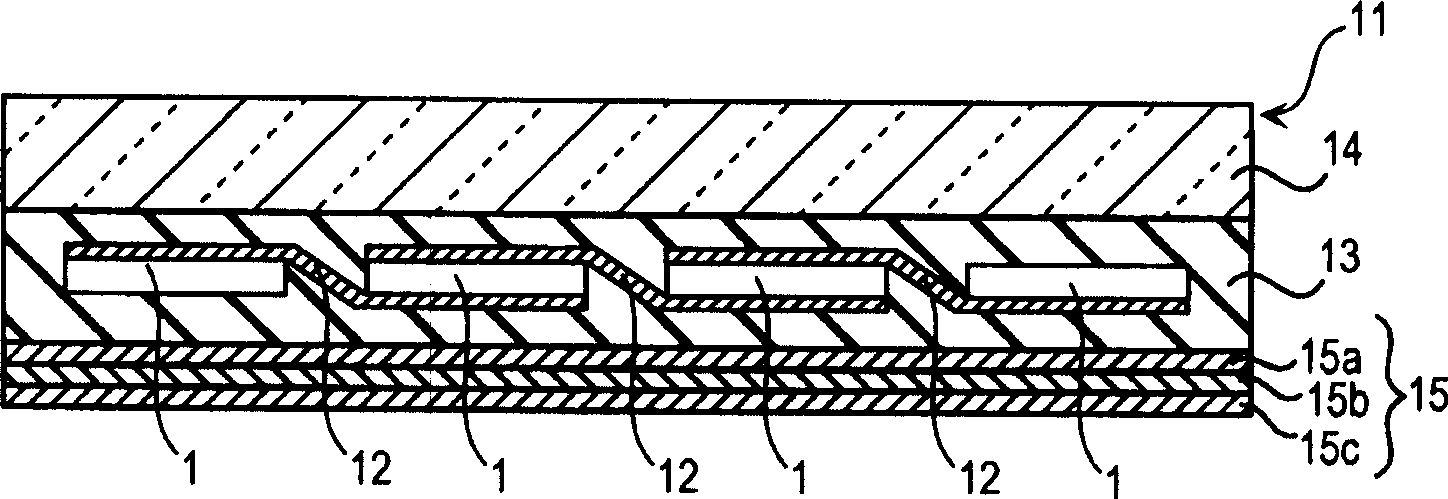

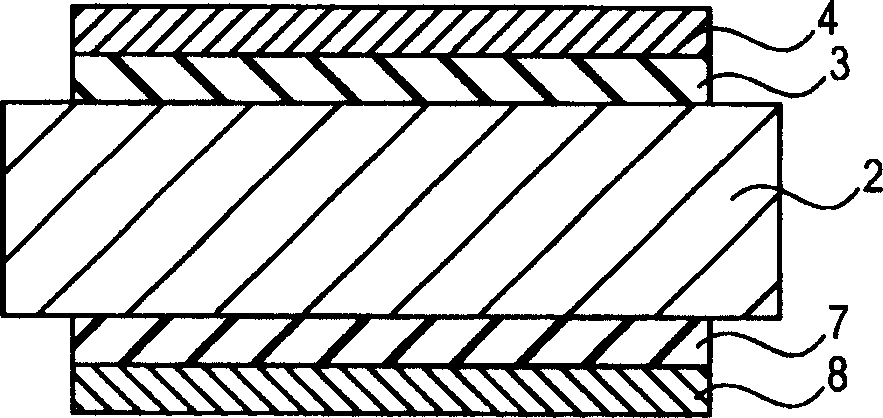

[0122] Solar cell element 1 with figure 1 , 3 Same as shown in 4. That is, as described above, the substantially intrinsic i-type amorphous silicon layer 3 and the p-type amorphous silicon layer 4 are continuously formed on the n-type monocrystalline silicon substrate 2 .

[0123] Furthermore, an ITO film 5 is formed on the p-type amorphous silicon layer 4 . A collector electrode (slurry electrode) 6 is formed in a predetermined region on the upper surface of the ITO film 5 . The collector electrode 6 includes a conductive filler made of silver (Ag) and a thermosetting resin. The thermosetting resin in collector electrode 6 contains epoxy resin in a volume ratio of 70% to 100%. If the proportion of epoxy resin in the resin binder is less than 100%, the other resin components in the resin binder are all polyurethane resins.

[0124] An i-type amorphous silicon layer 7 and an n-type amorphous silicon layer 8 are sequentially formed on the lower surface of the n-type monocr...

Embodiment 1-2

[0164] In Example 1-2, a resin material containing 70 vol % bisphenol-A epoxy resin and 30 vol % polyurethane resin was used for the conductive paste (silver paste) to form the collector electrodes 6 and 10 . Except for this, the solar cell module of Example 1-2 was prepared as in Example 1-1.

Embodiment 1-3

[0166] In Examples 1-3, a resin material containing 90 vol % bisphenol-A epoxy resin and 10 vol % polyurethane resin was used for the conductive paste (silver paste) to form the collector electrodes 6 and 10 . Except for this, the solar cell module of Example 1-3 was prepared as in Example 1-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com