Member for regenerating joint cartilage and process for producing the same, method of regenerating joint cartilage and artificial cartilage for transplantation

A technology of articular cartilage and culture method, applied in tissue regeneration, medical science, prosthesis, etc., can solve problems such as difficulty in early regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0199] 100 mg of PLA-DX-PEG (PLA: DX: PEG=45: 17: 38 (mole ratio)) and 20 μg of rhBMP-2 were mixed and diluted with acetone to prepare a gel-like mixture.

[0200] Use this gel-like mixture to infiltrate the hydroxyapatite porous body (diameter 4mm, length 4mm, porosity 75%, average pore diameter 200 μm, the volume of pores above 5 μm measured by mercury porosimeter accounted for 97% or more), after a certain period of time, the acetone is volatilized, and a uniform mixed layer of bioabsorbable materials and bone formation induction factors is formed on the inner surface of the pores of the hydroxyapatite porous body, and the articular cartilage regeneration is obtained. Material.

[0201] The obtained material for regeneration of articular cartilage was embedded in the articular surface of the rabbit femur with holes made according to the size, the joint was restored, and the incision site was sutured.

[0202] At this time, the material for regeneration of articular cartil...

Embodiment 2

[0230] A porous body made of hydroxyapatite with a porosity of 75% and a pore diameter of 200 μm was produced by stirring and foaming, and processed into a cylindrical body with a diameter of 4 mm and a length of 4 mm.

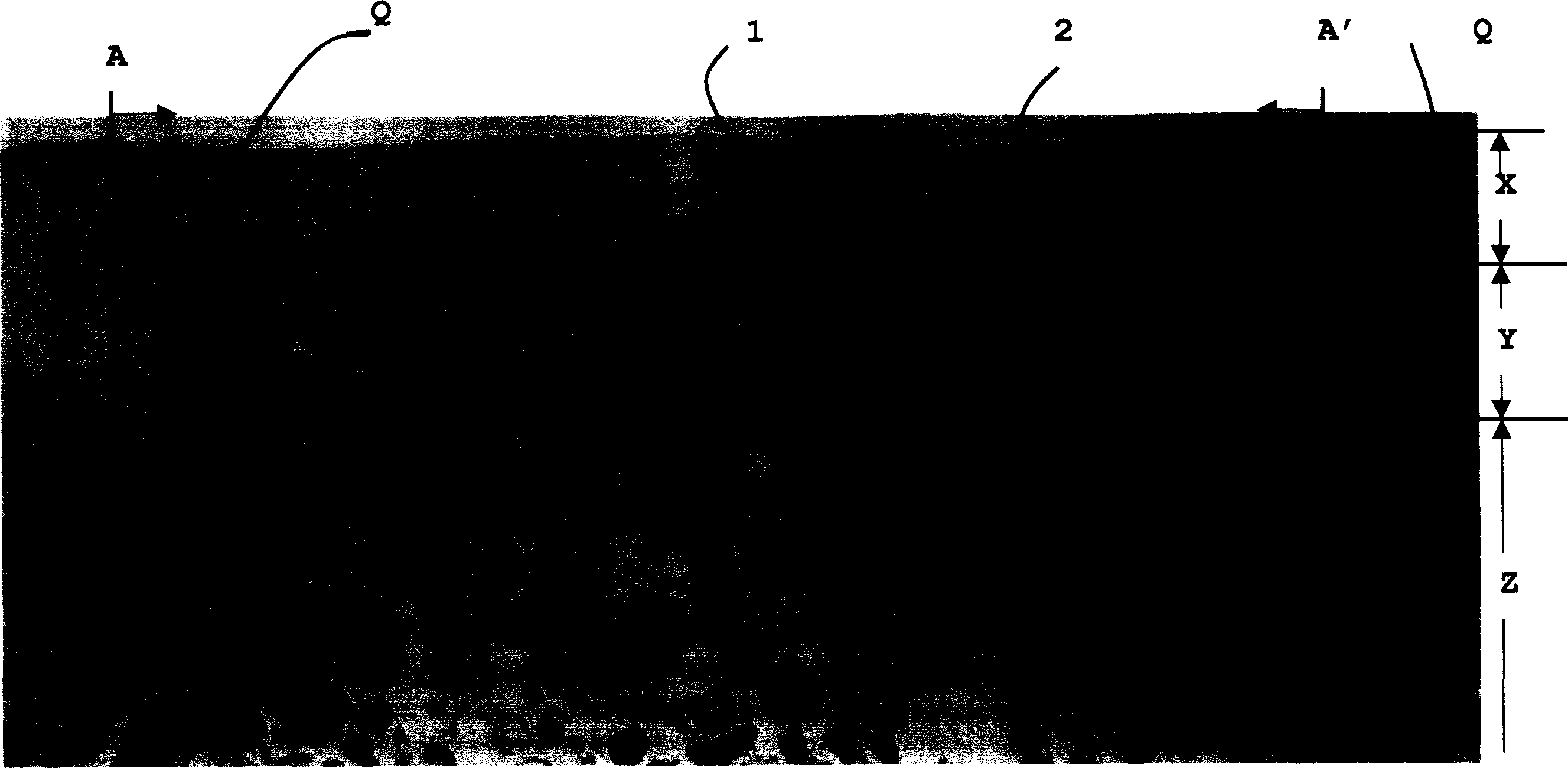

[0231] Cut the knee joint of the rabbit, and punch a hole with a diameter of 4mm on the articular surface of the femur. The hole is as deep as a part reaches the growth cartilage layer 3, and the obtained porous body is buried in the hole. The surface is deeper than the articular cartilage layer. 1mm, that is, the position of d=1mm in Figure 11, and then restore the joint, and then suture the incision site to achieve a movable state.

[0232] Five rabbits (n=5) were subjected to the above treatments.

Embodiment 3

[0234] The same porous body made of hydroxyapatite as in Example 2 was produced.

[0235] This porous body was buried at a place 2mm deeper than the articular cartilage layer on its surface, that is, the position of d=2mm in Fig. 11, and everything else was the same as in Example 2, and the rabbit's knee joint was treated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com