Method and device for mixing and burning sludge by circulating fluidized bed boiler

A circulating fluidized bed and sludge technology, which is applied in the field of sludge conveying equipment and circulating fluidized bed boilers, can solve the problem of difficult removal of water in sludge, occupies a large space, and cannot continue to play a cohesive role And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

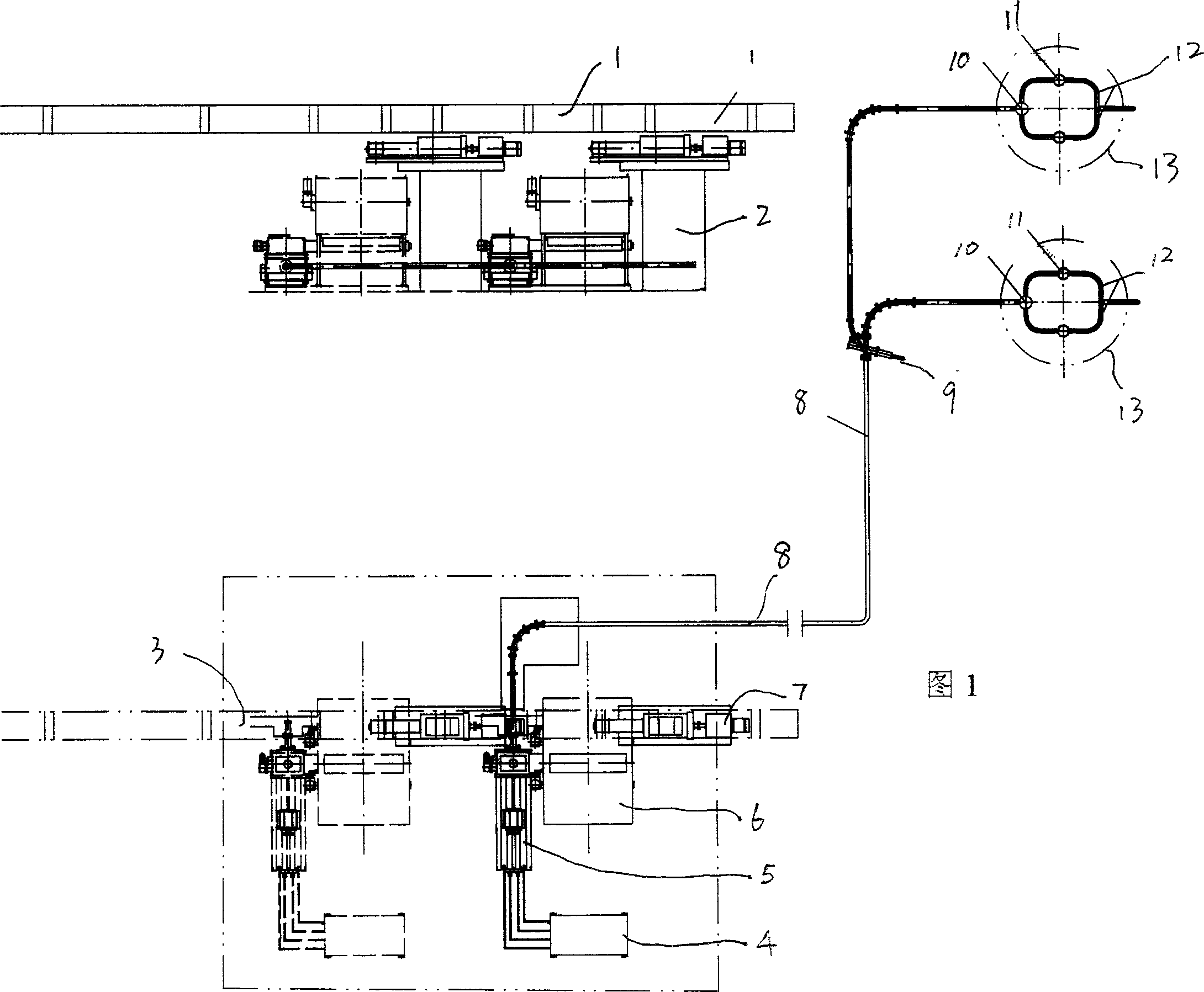

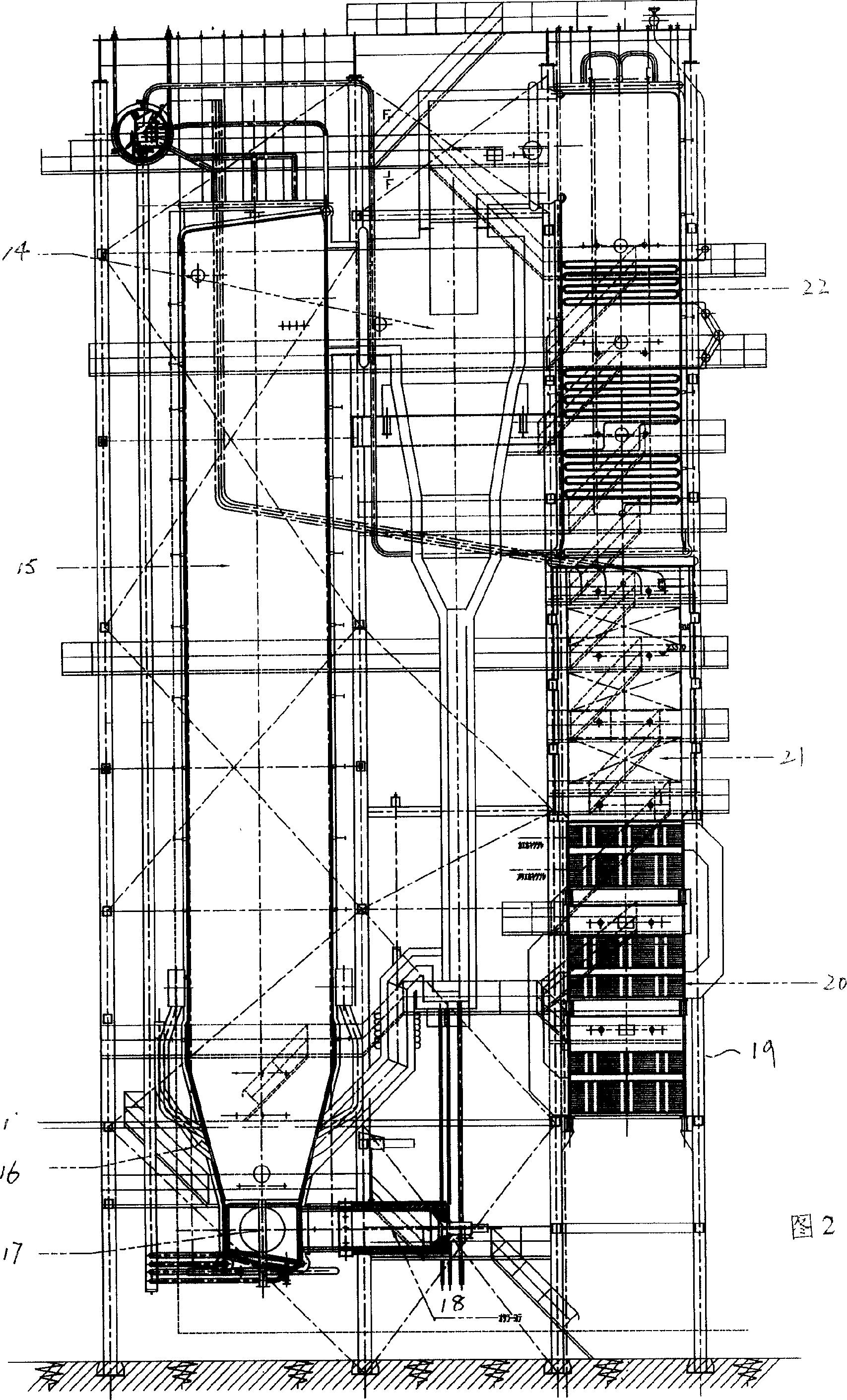

[0016] The method of mixing sludge with circulating fluidized bed boiler is as follows:

[0017] a. Knead in the kneading machine first to crush larger lumps;

[0018] b. Send it to the stirring buffer bin to stir evenly and accumulate a certain amount.

[0019] c. Reuse the sludge pump to send it into the furnace of the circulating fluidized bed boiler through the pipeline in the upper or middle upper negative pressure area of the circulating fluidized bed boiler;

[0020] d. The amount of sludge added is within 100% of the weight of the fuel, and the moisture content of the sludge is 25% to 90%;

[0021] e. The high-moisture sludge is dried and preheated and combustibles are burned while it is falling in the furnace. Zone, after 2 to 6 seconds of pyrolysis, is completely eliminated.

[0022] The added amount of the sludge can account for 25%-100% of the weight of the fuel. The calorific value of the sludge is 500 kcal when the corresponding water content is 80%, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com