Oil smoke exhausting and ventilating composite noise eliminator

A muffler device and oil fume exhaust technology, which is applied in the direction of oil fume removal, household heating, lighting and heating equipment, etc., can solve problems such as reduction, and achieve the effect of good noise reduction and sound muffling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

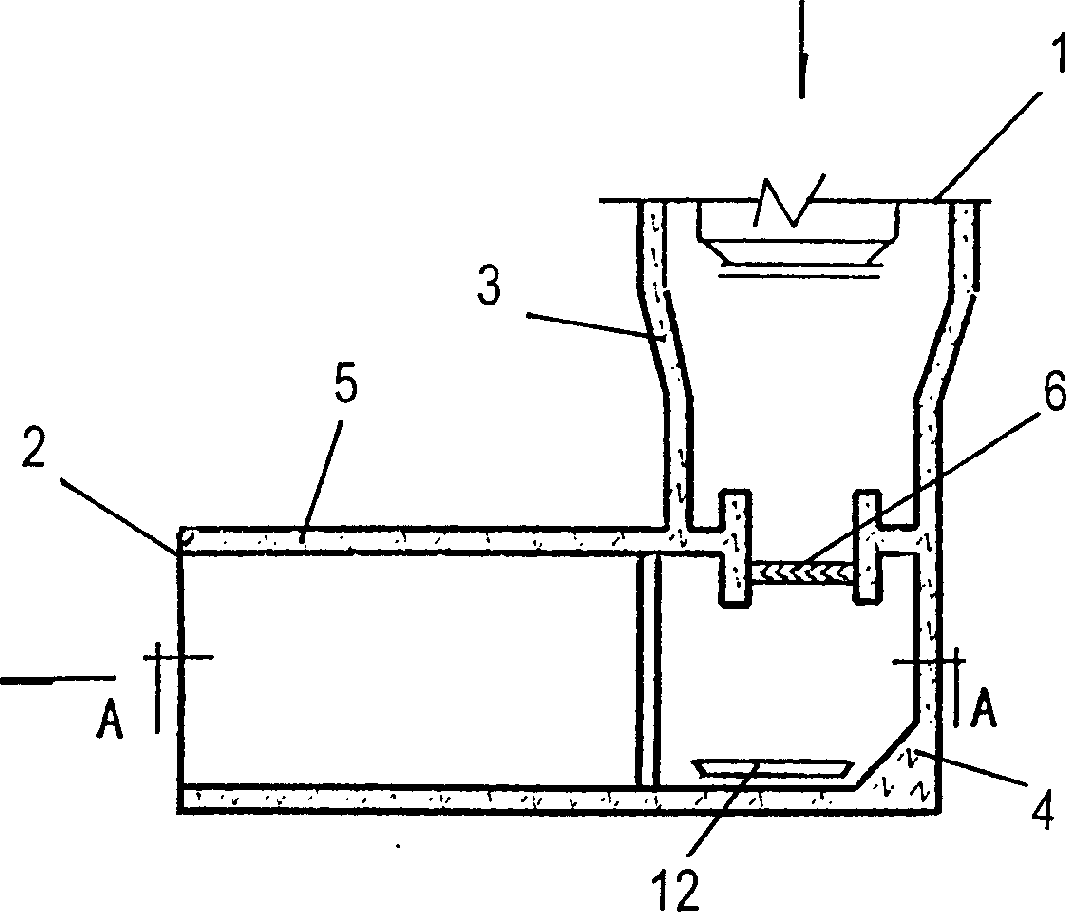

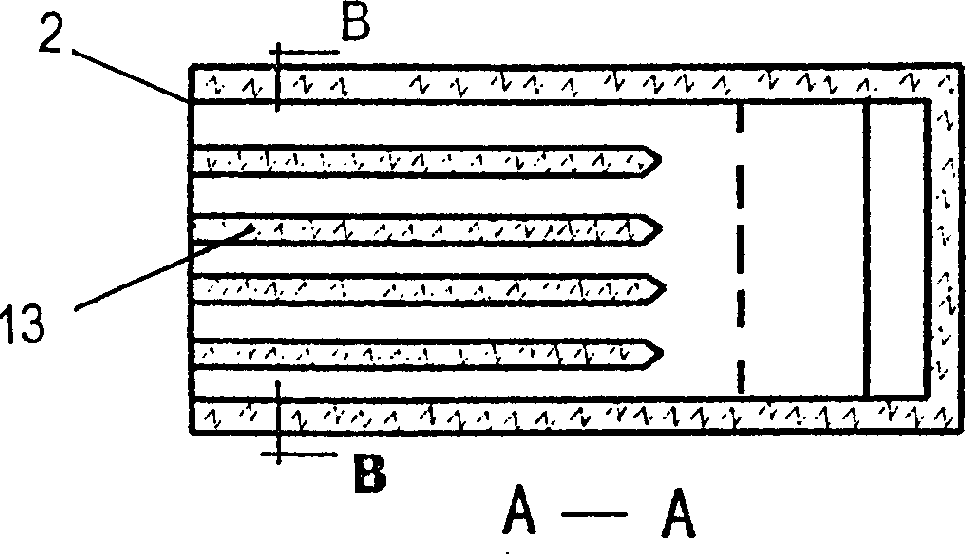

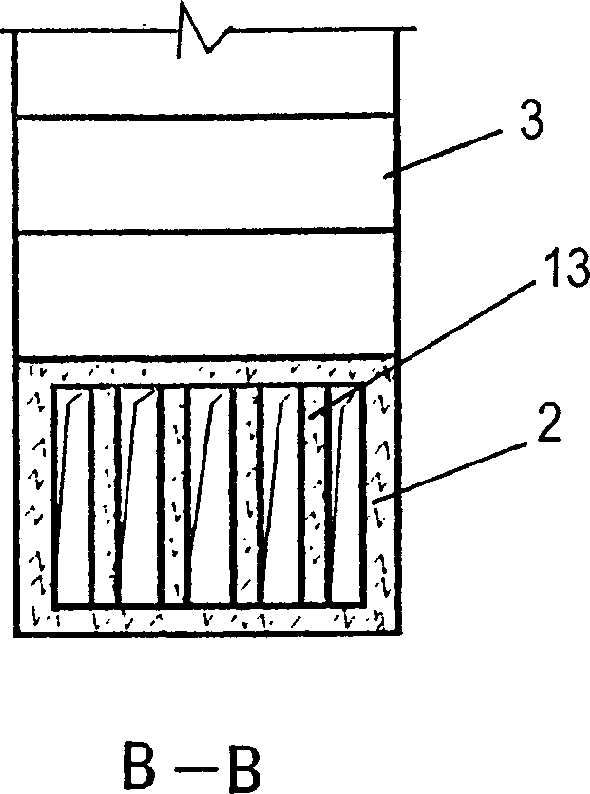

[0020] see figure 1 In this embodiment, from the oil fume inlet 1 to the oil fume outlet 2, the oil fume purifier 3, the expansion muffler section 4 and the resistive muffler section 5 are sequentially arranged in series, wherein the expansion muffler section 4 is in the shape of an "L" elbow.

[0021] Catering fume is a mixture of volatile oils, organic matter, and thermal oxidation and thermal cracking during food cooking and food processing, and there are nearly a hundred compounds. Cooking fume includes three phases of gas, liquid, and solid. The particle size of liquid-solid particles is generally less than 10 μm. The mixture of liquid-solid particles has strong adhesion, most of them are insoluble in water, and have low polarity. The anti-oil mist measures specifically adopted in this embodiment include:

[0022] 1. Set the outlet of the oil fume purifier 3 as Image 6 The shown "herringbone" type air intake baffle 6, under the air intake baffle 6, should be placed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com