Multiple drive conveyor system

A conveyor, motion technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of difficult maintenance, cleaning and cleaning of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

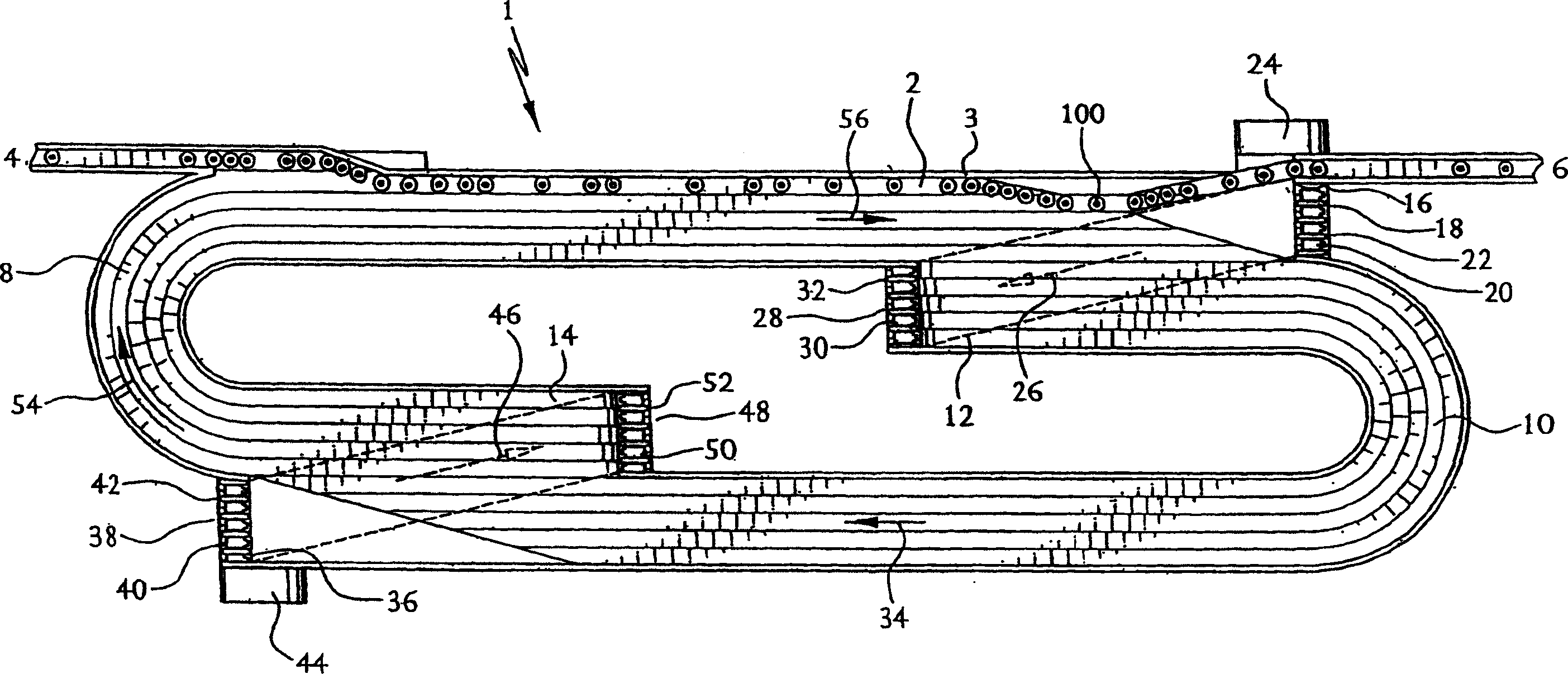

[0025] The conveyor system 1 comprises a single loop continuous path conveyor 2, which can be installed on the ground, for example on a raised frame 3, as is commonly used in the industry. The conveyor 2 is configured to move and accumulate products, such as bottles 100, from the upstream position marked 4 to the downstream position marked 6. The conveyor 2 includes product carrying sections 8, 10 and offset return path sections 12, 14. It is envisaged that these sections of the conveyor 2 can be configured as interlocking chain sections, as is well known in the art. The sections 8, 10, 12 and 14 form the continuous conveyor 2. All these conveyor sections are located in the same transverse plane.

[0026] When the chain sections constituting the product carrying section 8 reach the position marked 16, they are connected to the drive sprocket assembly 18, which includes a bearing support shaft 20 supporting the sprocket 22. The shaft 20 is mechanically connected to a power unit, su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com