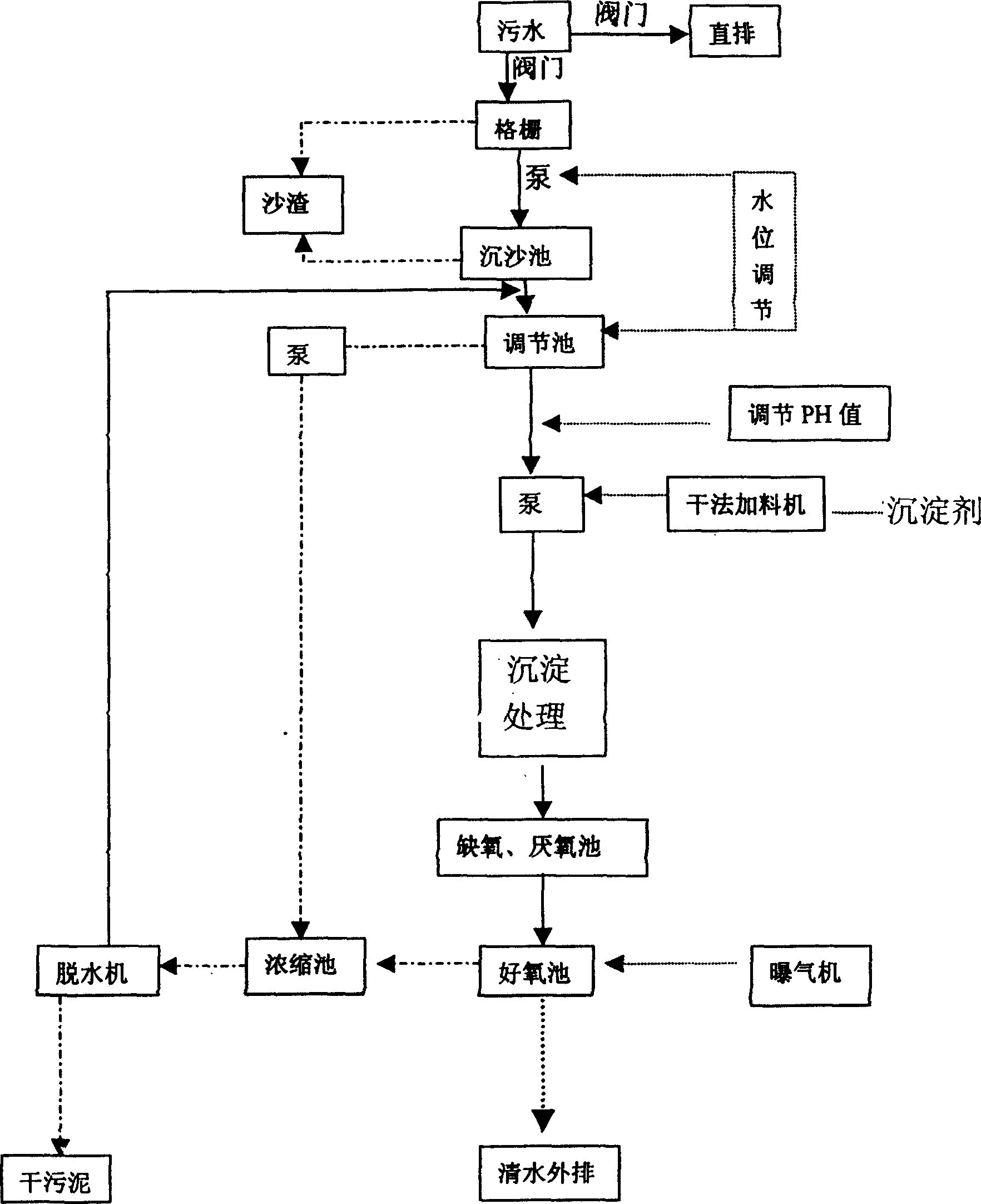

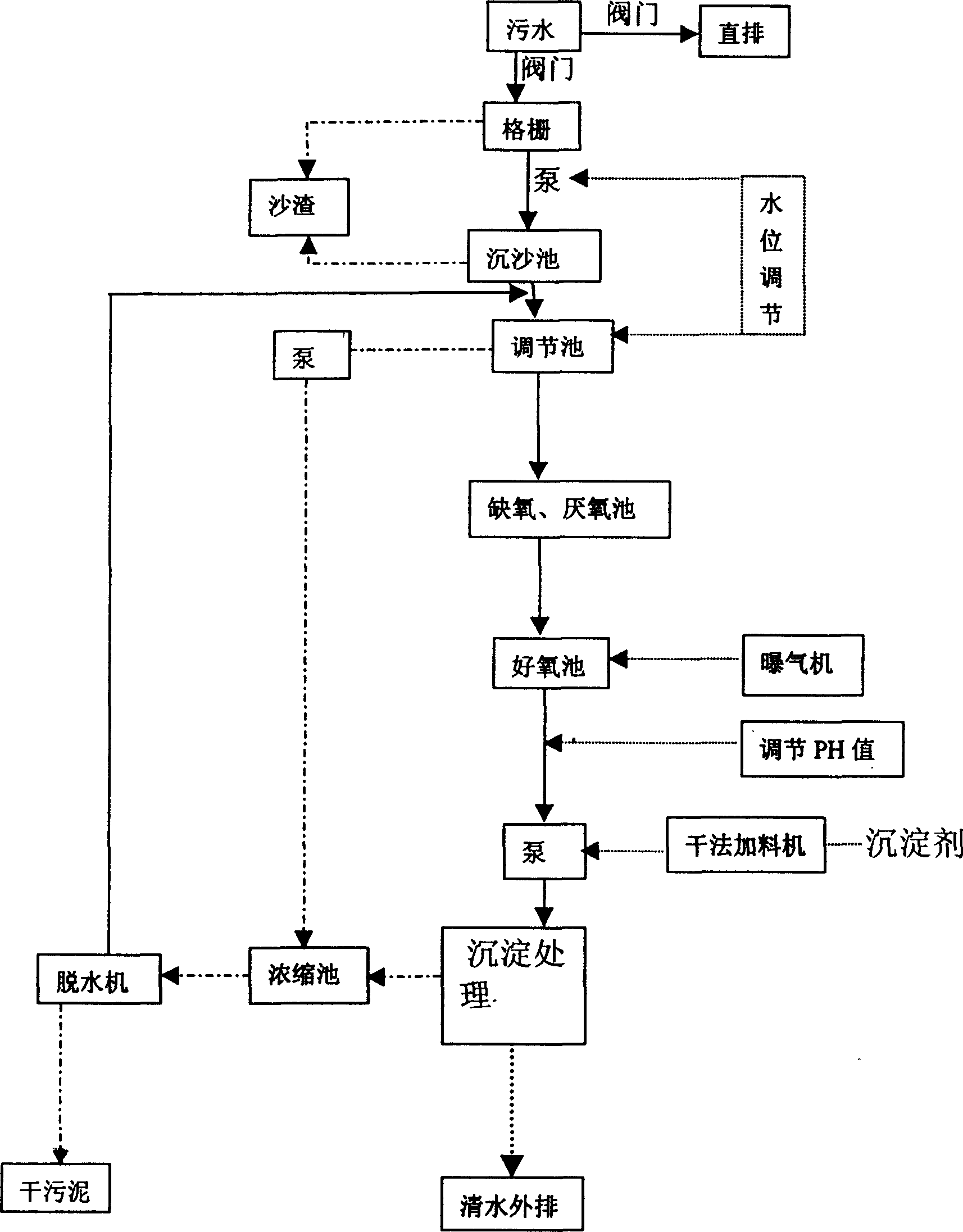

High efficiency sewage treatment method

A sewage treatment method and sewage technology, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Unsatisfactory, limited processing capacity and other problems, to achieve the effect of stable processing effect, reducing supporting investment, and facilitating centralized management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The treated sewage water quality is as follows: COD cr 500mg / L, BOD 5 150mg / L, SS≤200mg / L, NH 3 -N≤100mg / L, T-P≤5mg / L, pH=6.5-9.0.

[0029] The treated effluent quality is as follows: COD cr 50mg / L, removal rate over 90%, BOD 5 10mg / L, the removal rate is above 93.3%, SS≤10mg / L, the removal rate is above 95%, NH 3 -N≤8mg / L, the removal rate is above 92%, T-P≤1mg / L, the removal rate is above 80%, pH=6-9.

[0030] The specific treatment is as follows:

[0031] 1. Pretreatment: send the sewage from the sump to the mechanical grille, and control the flow rate of the screen to 15000-35000m 3 / d, remove the large particles and fiber impurities, and then send it to the grit chamber, control the flow rate in the canal to 0.9m / s, stay for 30s, remove the sand particles with a specific gravity of 2-3 and a particle size above 0.2mm, and send the sewage into the In the primary sedimentation tank, the sedimentation time is controlled for 1.8 hours, the sewage is sent to th...

Embodiment 2

[0039] The treated sewage water quality is as follows: COD cr 400mg / L, BOD 5 100mg / L, SS=180mg / L, NH 3 - N = 90 mg / L, T-P = 3.8 mg / L, pH = 6.5.

[0040] The treated effluent quality is as follows: COD cr 55mg / L, BOD 5 11mg / L, SS=12mg / L,, NH 3 -N=9 mg / L, T-P=1 mg / L, pH=9.

[0041] The specific treatment is as follows:

[0042] 1. Pretreatment: send the sewage from the sump into the mechanical grille, and control the flow rate of the screen to 15000-35000m 3 / d, remove the large particles and fiber impurities, and then send it to the grit chamber, control the flow rate in the canal to 0.9m / s, stay for 30s, remove the sand particles with a specific gravity of 2-3 and a particle size above 0.2mm, and send the sewage into the In the primary sedimentation tank, the sedimentation time is controlled for 1.8 hours, the sewage is sent to the biochemical system, and the sand residue is discharged into the sand residue tank;

[0043] 2. Biochemical treatment: Introduce sewage in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com