Trans-critical refrigerating unit

A refrigeration device, transcritical technology, applied in the direction of refrigerators, components of pumping devices for elastic fluids, refrigeration components, etc., to achieve the effect of suppressing sliding loss and suppressing leakage loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

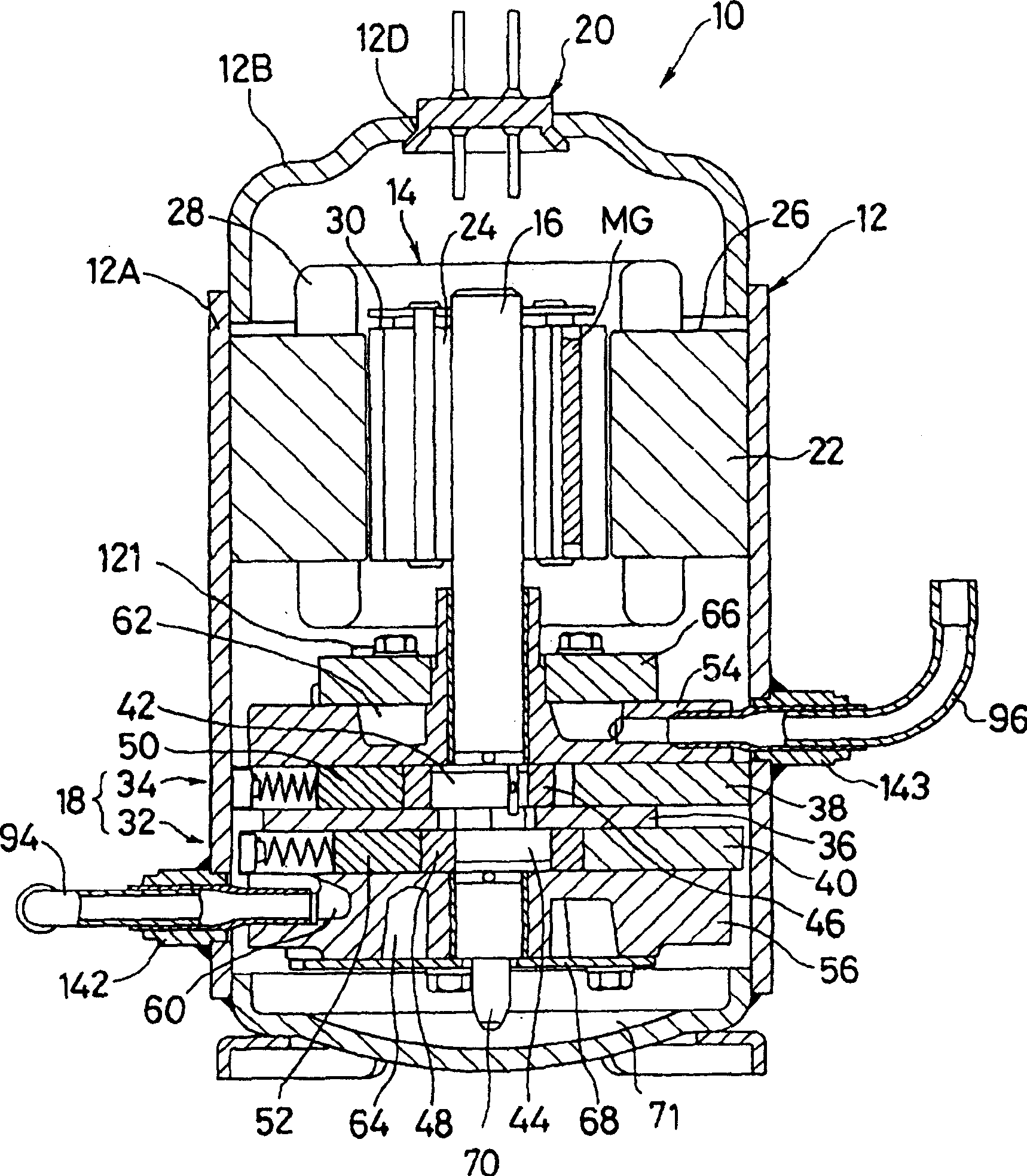

Method used

Image

Examples

Embodiment 1

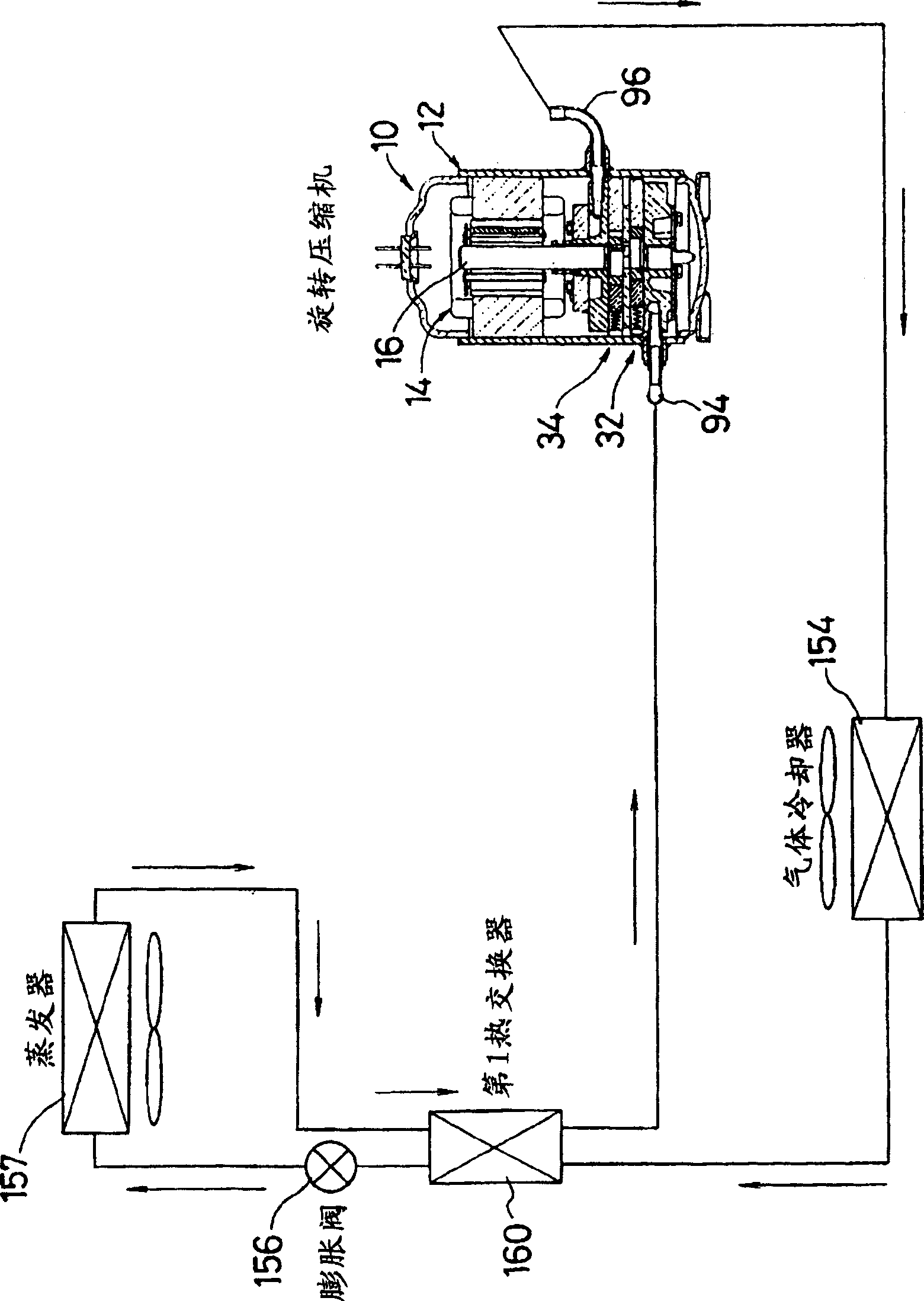

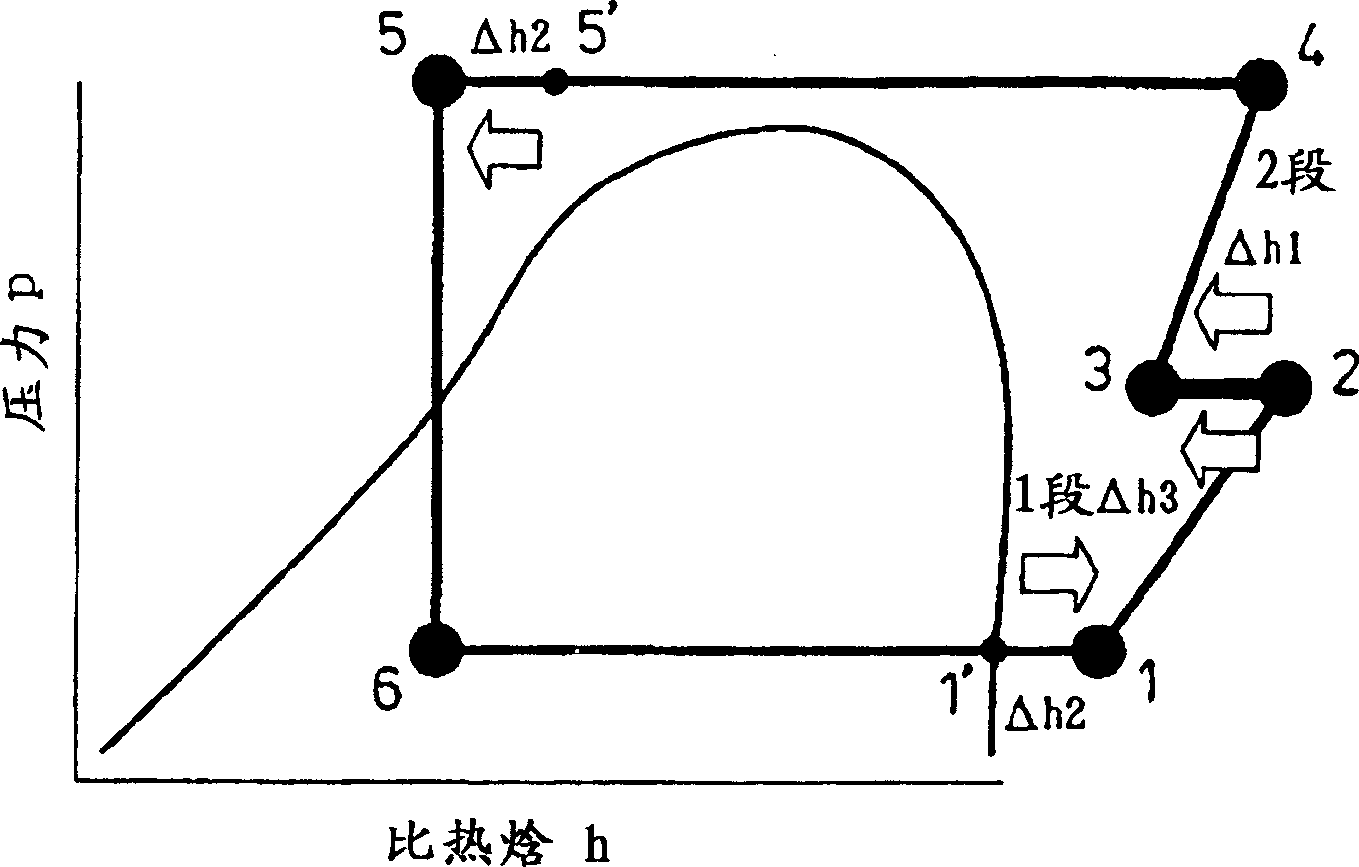

[0075] When used with Figure 4 The transcritical refrigeration device of the present invention of the refrigerant circuit shown in 2 ) was used as the refrigerant, and the lubricating oil listed in Table 1 was used, and the test operation was carried out under the two-stage compression condition of 9 MPa on the high pressure side and 3 MPa on the low pressure side. Results for capacity, input, COP and speed.

[0076]

[0077] PAG46

Embodiment 2

[0079] When using the following 2-stage compression conditions 1 and 2-stage compression conditions 2, and the lubricating oil recorded in Table 1 to carry out 2-stage compression, and other conditions are the same as in Example 1, in Table 3 and Figure 5 The results of the COP obtained during the test run are shown in .

[0080] (2-stage compression condition 1) The pressure on the high pressure side is 9MPa, and the pressure on the low pressure side is 3MPa.

[0081] (2-stage compression condition 2) The pressure on the high pressure side is 12 MPa, and the pressure on the low pressure side is 3.8 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com