Large mode field area large chromatic dispersion photonic crystal fiber

A photonic crystal fiber, large mode field technology, applied in the direction of light guide, optics, optical components, etc., to achieve the effect of large mode field area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

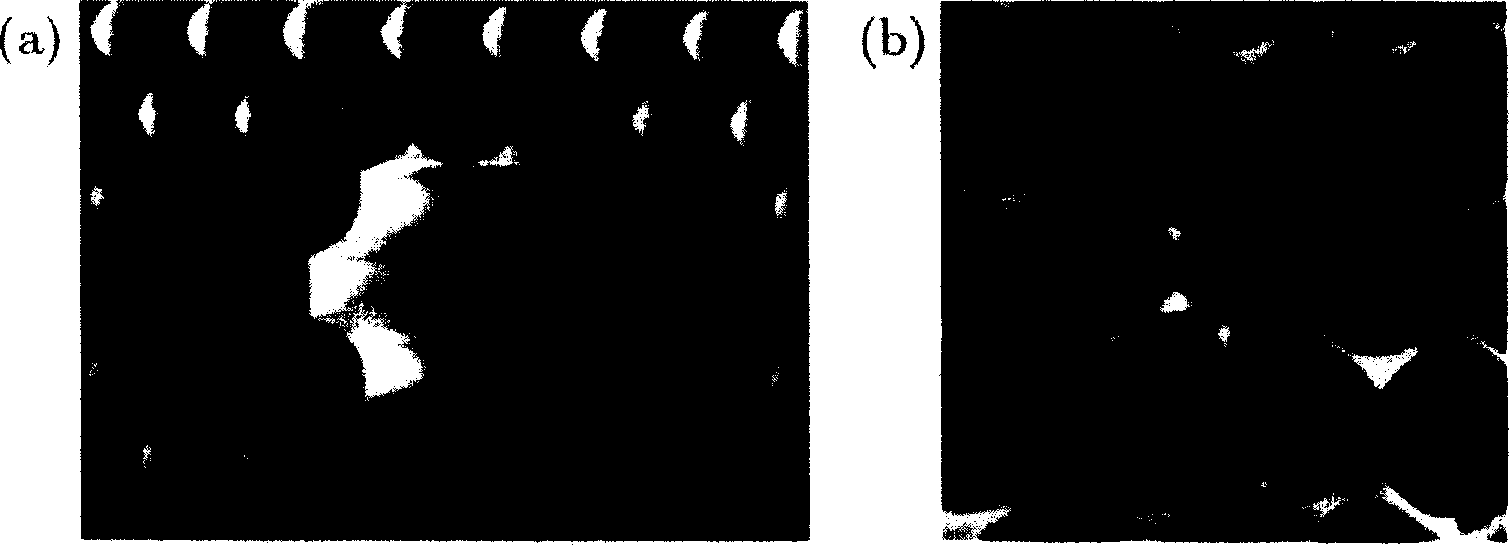

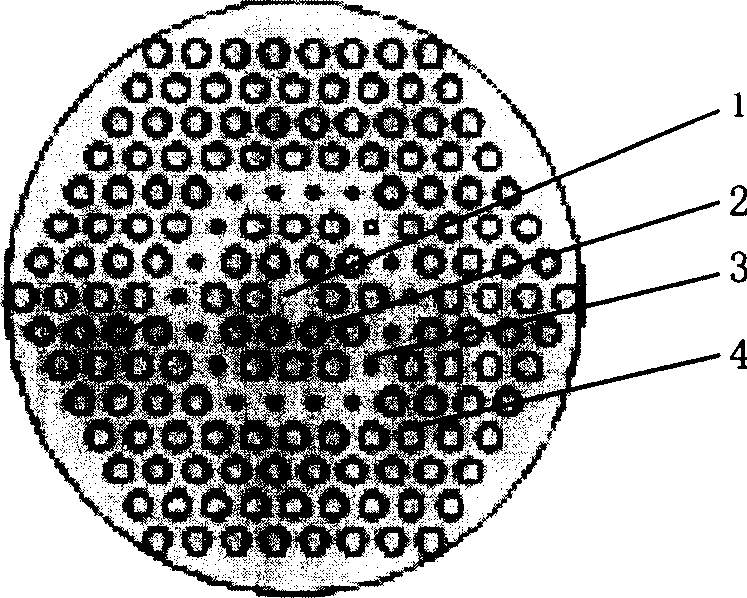

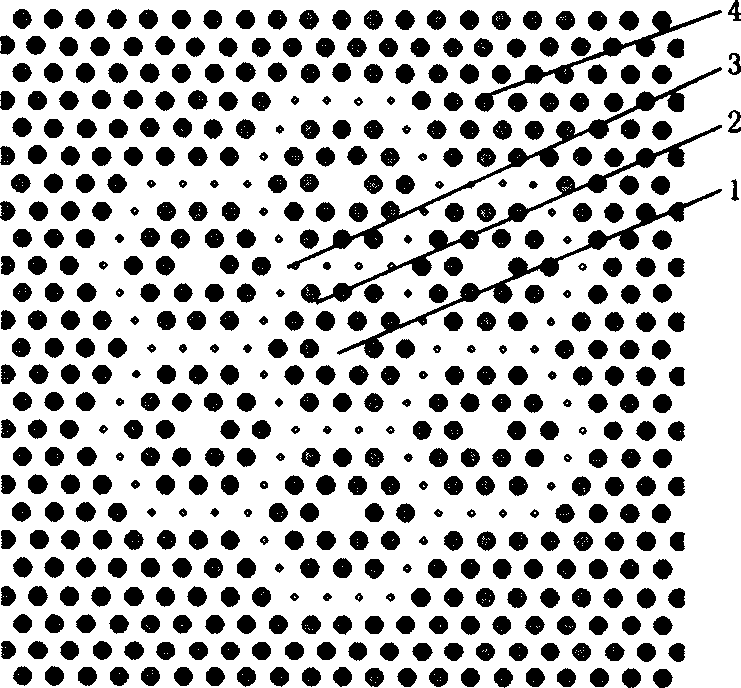

[0019] The large dispersion fiber includes seven groups of asymmetrically coupled double-core structures. Among them, six sets of double-core structures are evenly distributed along the circumferential direction. Another double-core structure is located in the center of the circumference. Each group is an asymmetrically coupled two-core structure. This asymmetrically coupled two-core structure can form a supermode. When the wavelength is changed, the distribution of supermodes in space will change. For example, when the wavelength is smaller than the phase matching wavelength of the inner core and the outer core, the mode field is distributed in the inner core; when it is in the phase matching wavelength of the inner core and the outer core, the mode field is distributed in the inner core and the outer core at the same time; When matching wavelengths, the mode field is mainly distributed in the outer core. The refractive index of the inner core and the outer core is differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com