Photonic crystal fiber and preparation method thereof

A photonic crystal fiber and photonic crystal technology, applied in cladding fiber, optical waveguide light guide, microstructure fiber, etc., can solve the problems of high incident power, small fiber core diameter, unbearable, etc., and achieve easy preparation and low mode field area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

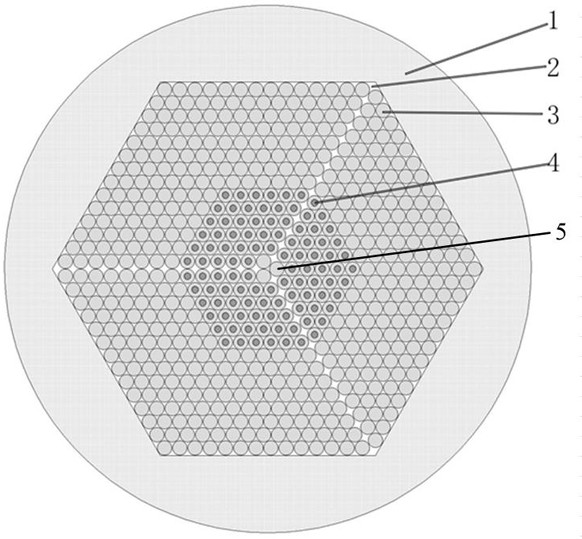

[0052] figure 1 and figure 2 It is a schematic structural diagram of each step of Embodiment 1 of the photonic crystal fiber manufacturing method of the present invention.

[0053] Please refer to figure 1 , perform step S1, manufacture the first glass rod 3, the second glass rod 4 and the third glass rod 5, the first glass rod 3 is used to form the cladding, and the second glass rod 4 is used to form the photonic crystal fiber Structure layer, the third glass rod 5 is used to form the fiber core; the diameters of the first glass rod 3, the second glass rod 4 and the third glass rod 5 are all the same; the refractive index of the second glass rod 4 less than the refractive index of the third glass rod 5; the refractive index of the second glass rod 4 is less than the refractive index of the first glass rod 3;

[0054] Specifically, in this embodiment, the first glass rod 3 is the same as the third glass rod 5 . The refractive index of the first glass rod 3 is equal to the...

Embodiment 2

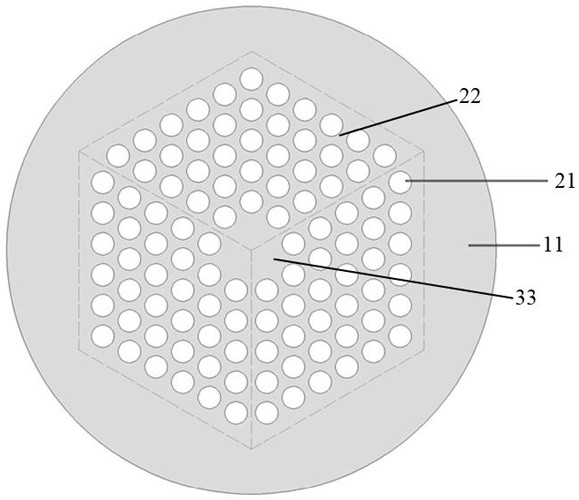

[0091] Figure 3 to Figure 5 It is a schematic structural diagram of each step of the second embodiment of the photonic crystal fiber manufacturing method of the present invention.

[0092] This example and figure 1 and figure 2 The similarities of the illustrated embodiments are not repeated here, and the differences include:

[0093] In this embodiment, the material of the first glass rod 3 and the third glass rod 5 is quartz. The core layer of the second glass rod 4 is air, and the cladding layer of the second glass rod 4 is quartz.

[0094] In this embodiment, the method for forming the second glass rod 4 includes: forming a hollow glass tube; and drawing the hollow glass tube into the second glass rod 4 , and the second glass rod 4 is a hollow glass rod.

[0095] The outer diameter of the hollow glass tube forming the second glass rod 4 is 22 mm˜28 mm, and specifically, the outer diameter of the hollow glass tube forming the second glass rod 4 is 25 mm. The inner di...

Embodiment 3

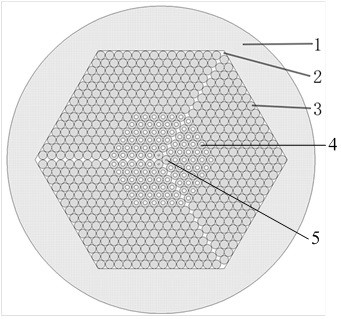

[0104] Figure 6 to Figure 8 It is a schematic structural diagram of Embodiment 3 of the preparation method of the photonic crystal fiber of the present invention.

[0105] refer to Figure 6 to Figure 8 , the similarities between this embodiment and the second embodiment are not repeated, and the differences include:

[0106] In this embodiment, the outer diameter of the hollow glass tube forming the second glass rod 4 is 22 mm˜28 mm, and specifically, the outer diameter of the hollow glass tube forming the second glass rod 4 is 25 mm. The inner diameter of the hollow glass tube forming the second glass rod 4 is 10 mm˜15 mm, and specifically, the inner diameter of the hollow glass tube forming the second glass rod 4 is 12.5 mm.

[0107] In this embodiment, the refractive index of the core layer of the third glass rod 5 is greater than the refractive index of the core layer of the second glass rod 4; the refractive index of the cladding layer of the third glass rod 5 is grea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com