A large mode field area all-solid-state optical fiber and its manufacturing method

An all-solid, large mode field technology, applied in cladding fibers, optical waveguides, etc., can solve the problems of high-power laser transmission is not the best, the center of the fiber is easily burned, and the single-mode characteristics of the fiber are destroyed. Achieve the effect of large mode field transmission capacity, increase damage threshold, and increase the degree of overlap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The content of the present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

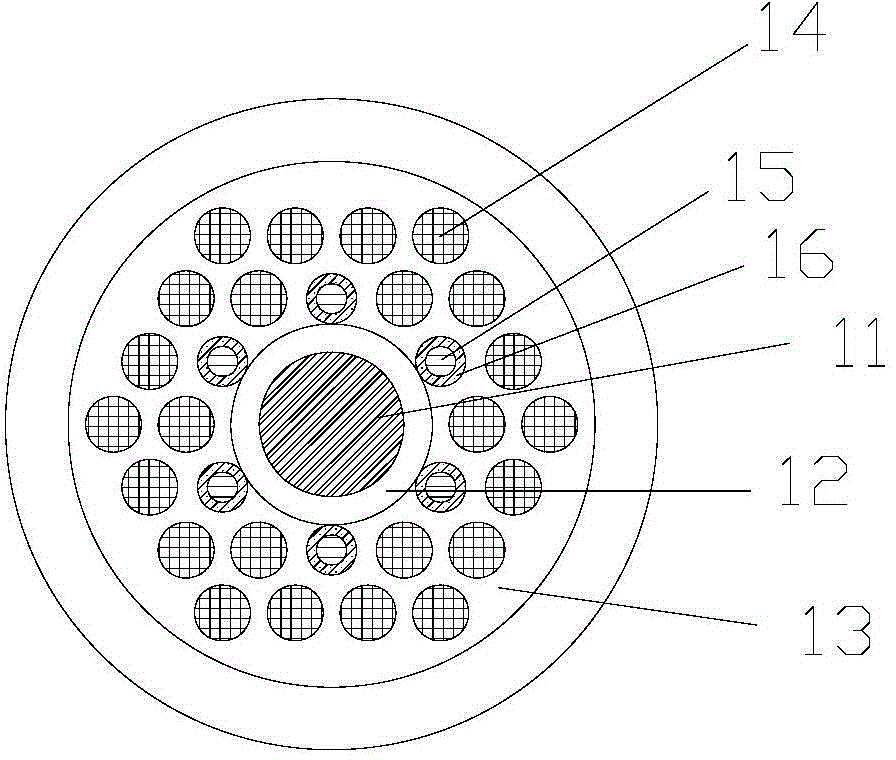

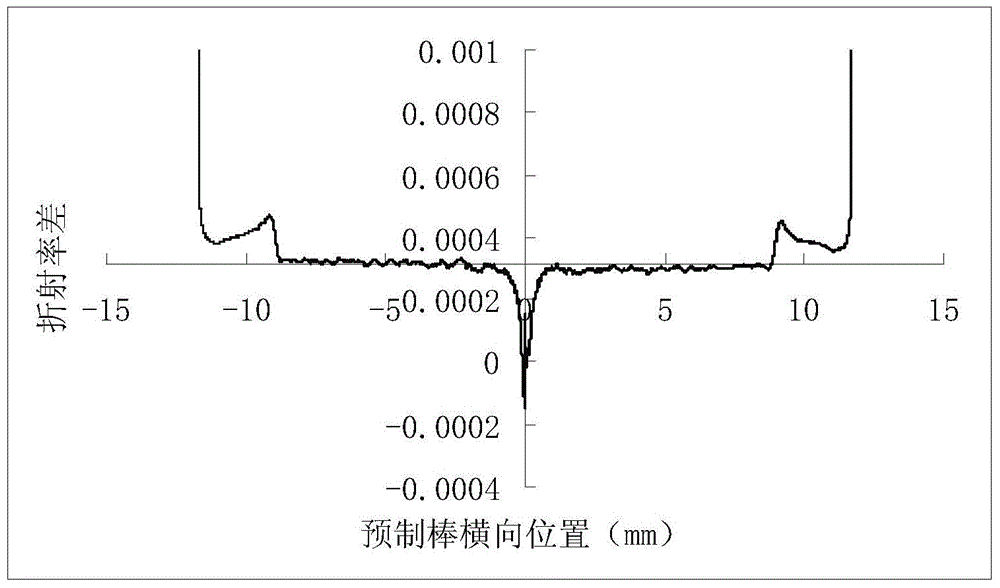

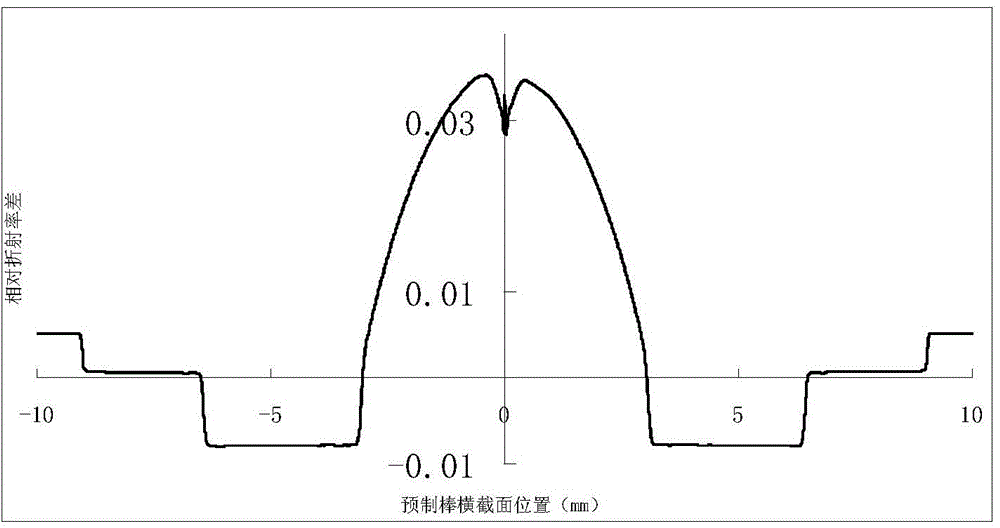

[0043] figure 1 It is a schematic diagram of the basic structure of an embodiment of the present invention. An optical fiber includes a core region and a cladding region. The core area is located in the center of the optical fiber, including the central area 11 and the edge part 12. The material in the central area is made of slightly fluorine-doped quartz glass, and the relative refractive index difference caused by fluorine doping is -0.01% (refers to the refractive index drop ratio), with a diameter of 25 μm; for the refractive index profile see figure 2 , the edge part is silica glass, which is the same material as 13. The cladding region uses pure silica glass as the substrate 13, and contains 2 layers of doping units arranged in periodic close packing, that is, the arrangement is the same as that of the photonic crystal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com