Flexible metal foil laminate producing apparatus and producing method utilizing the same apparatus

A flexible metal, lamination technology, applied in the direction of metal layered products, chemical instruments and methods, applications, etc., can solve the problems of product surface flatness and smoothness damage, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

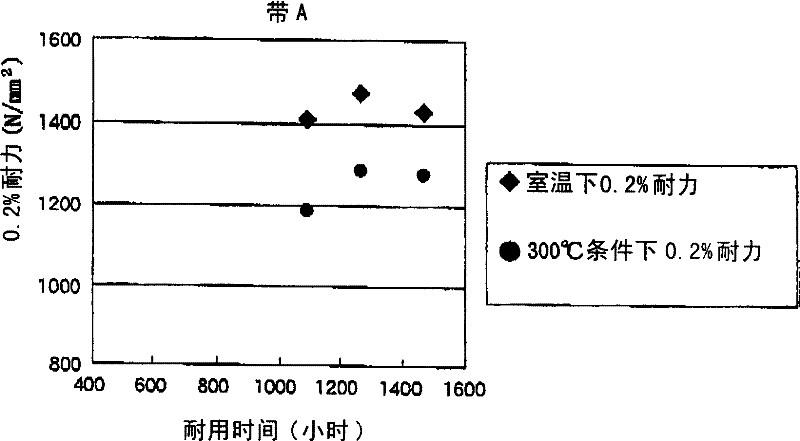

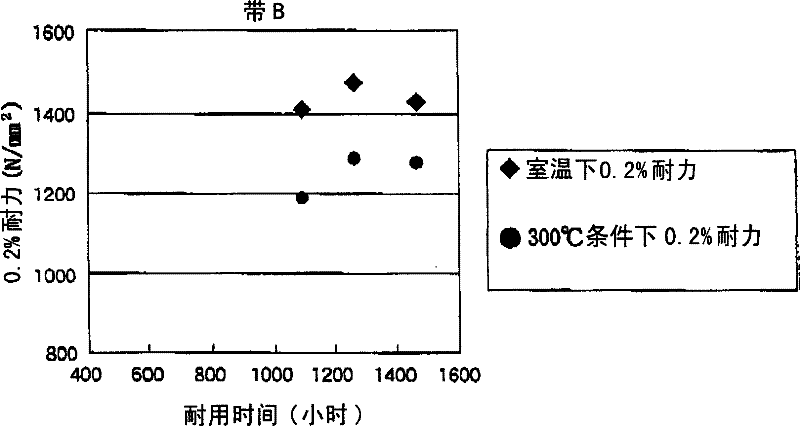

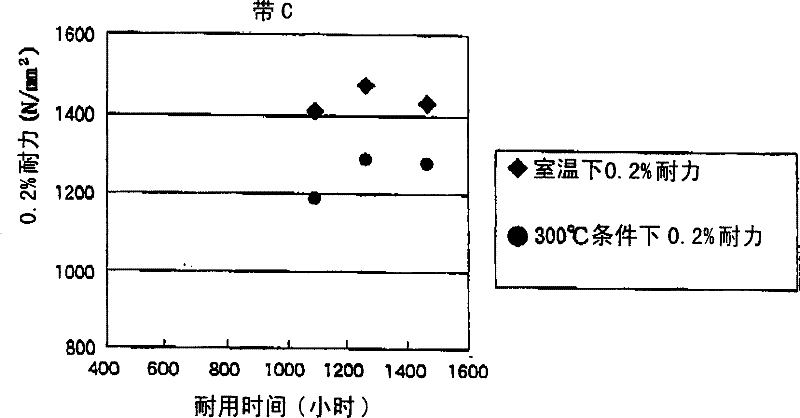

[0043] First, endless belts (A, B, and C) having three types of compositions shown in "Table 1" were prepared for a continuous preparation test to compare durability time and 0.2% endurance. Through continuous operation under the heating temperature condition of 300°C, a double-belt pressing method is adopted to realize continuous preparation and testing. For the sheet, a polyimide-based film (manufactured by Ube Industries, Ltd. under the trademark UPILEX, 25 micrometers in thickness), and copper foil (manufactured by Nippon Denkai, Ltd., 18 micrometers in thickness) can be used.

[0044] 〔Table 1〕

[0045] synthetic parts

[0046] Band A (weight percent)

[0047] Band B (weight percent)

[0048] Band C (weight percent)

[0049] The results of Example 1 of the present invention are illustrated in the following "Table 2" and appended to Figure 1 to Figure 3 middle. Figure 1 to Figure 3 It is a graph of "table 2" represented by a graph. figure 1 Indicates the result o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com