Prepn process of prefabricated rod for photon crystal fiber

A technology of photonic crystal fiber and preform, which is applied in glass manufacturing equipment, glass fiber products, manufacturing tools, etc., can solve problems such as interface loss and achieve the effect of overcoming the problem of interface scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with the examples and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

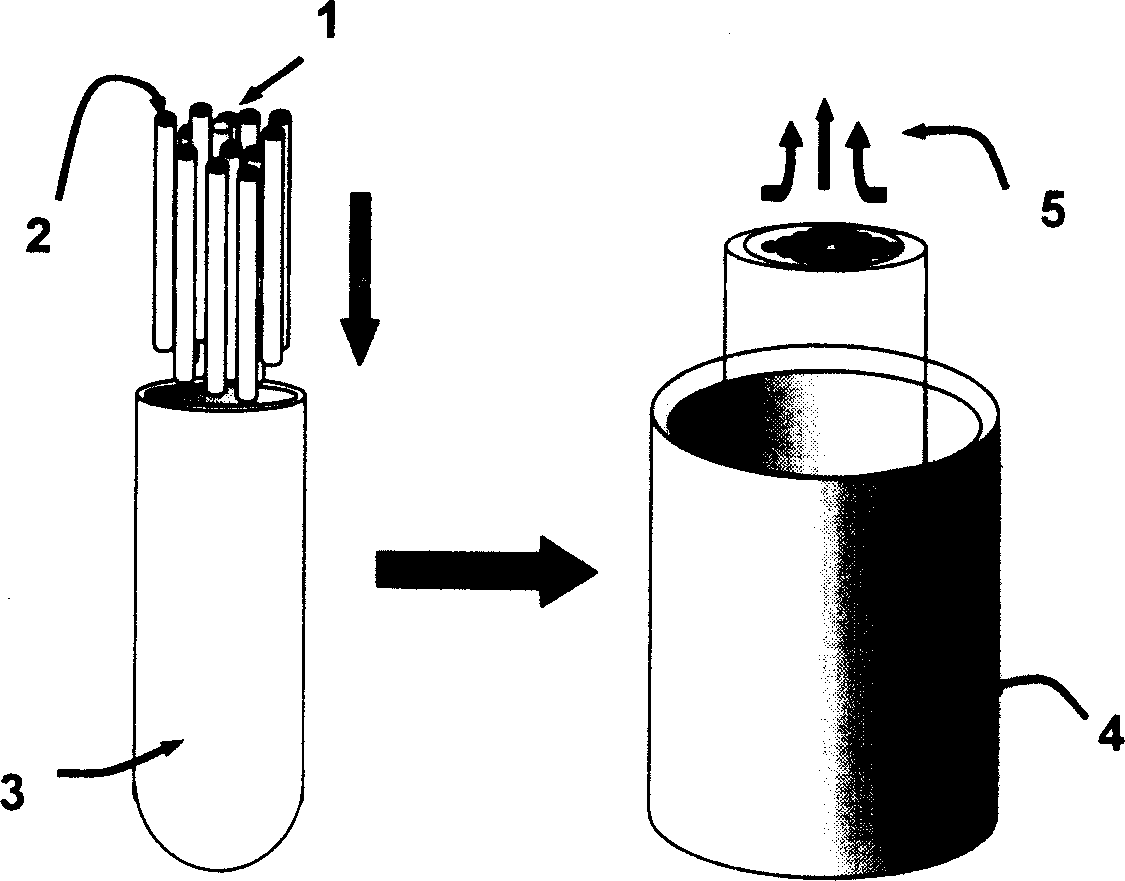

[0036] figure 1 Flow chart of making photonic crystal fiber preform for the present invention. The left part is a schematic diagram of filling the core-forming glass rod 1 and the capillary 2 into the jacket glass tube 3. The core-forming glass rod 1 and the capillary 2 are filled into the jacket glass tube 3 along the direction indicated by the vertical downward arrow. The right part is the process of placing the jacket glass tube 3 filled with the capillary 2 and the core-forming glass rod 1 in the heating furnace 4 for heating. Low air pressure inside the glass tube 3 tube. When the temperature of the heating furnace is kept higher than the softening point of the glass frit by 50°C to 200°C for about 120 minutes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com