Multi-frequency synthetic vibrating compacting method and multi-frequency synthetic vibration exciter for compacting machine

A technology of synthesizing vibration and vibration exciter, which is applied in the direction of fluid, soil protection, construction, etc. using vibration to achieve high work efficiency, low energy consumption, and good compaction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

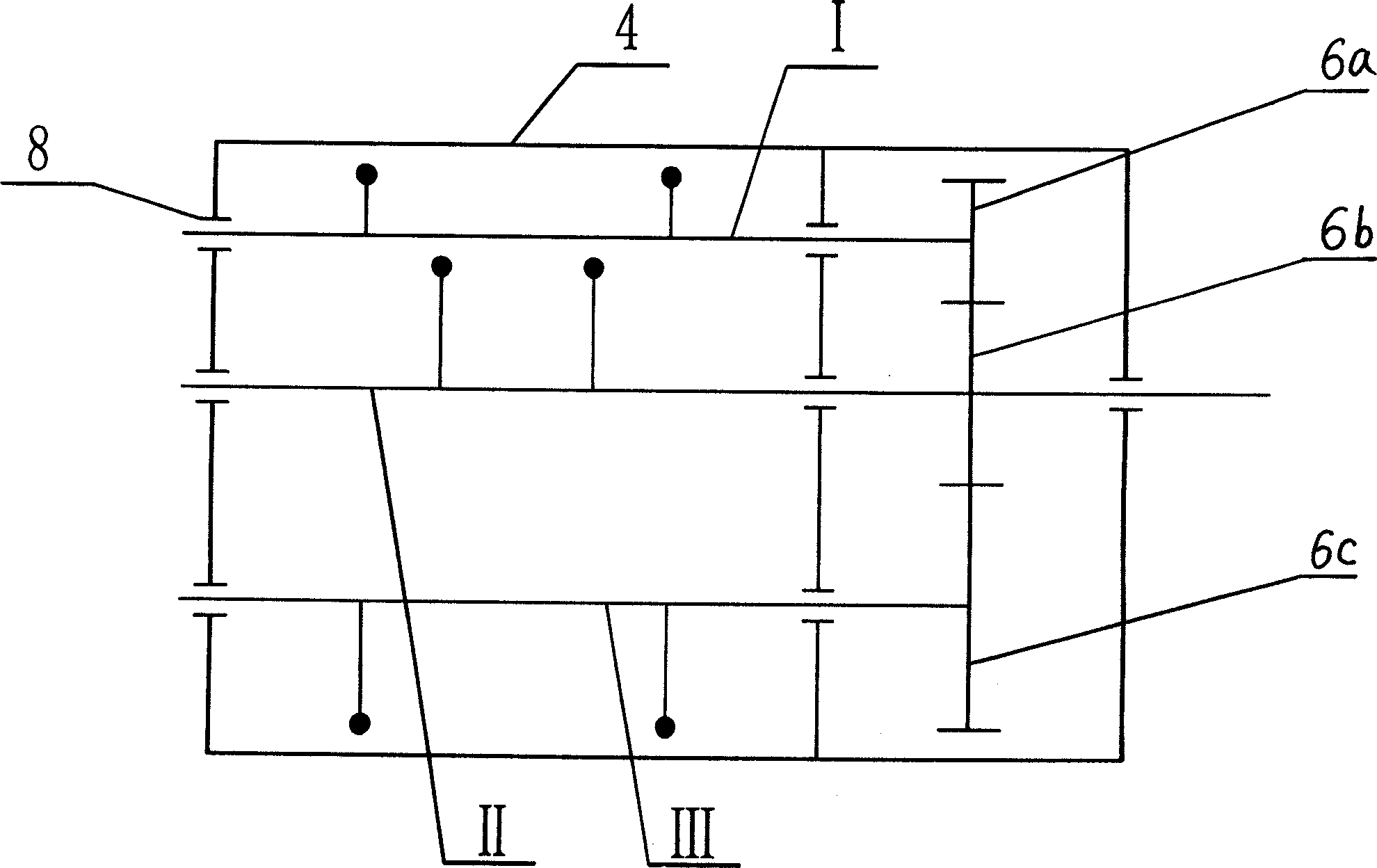

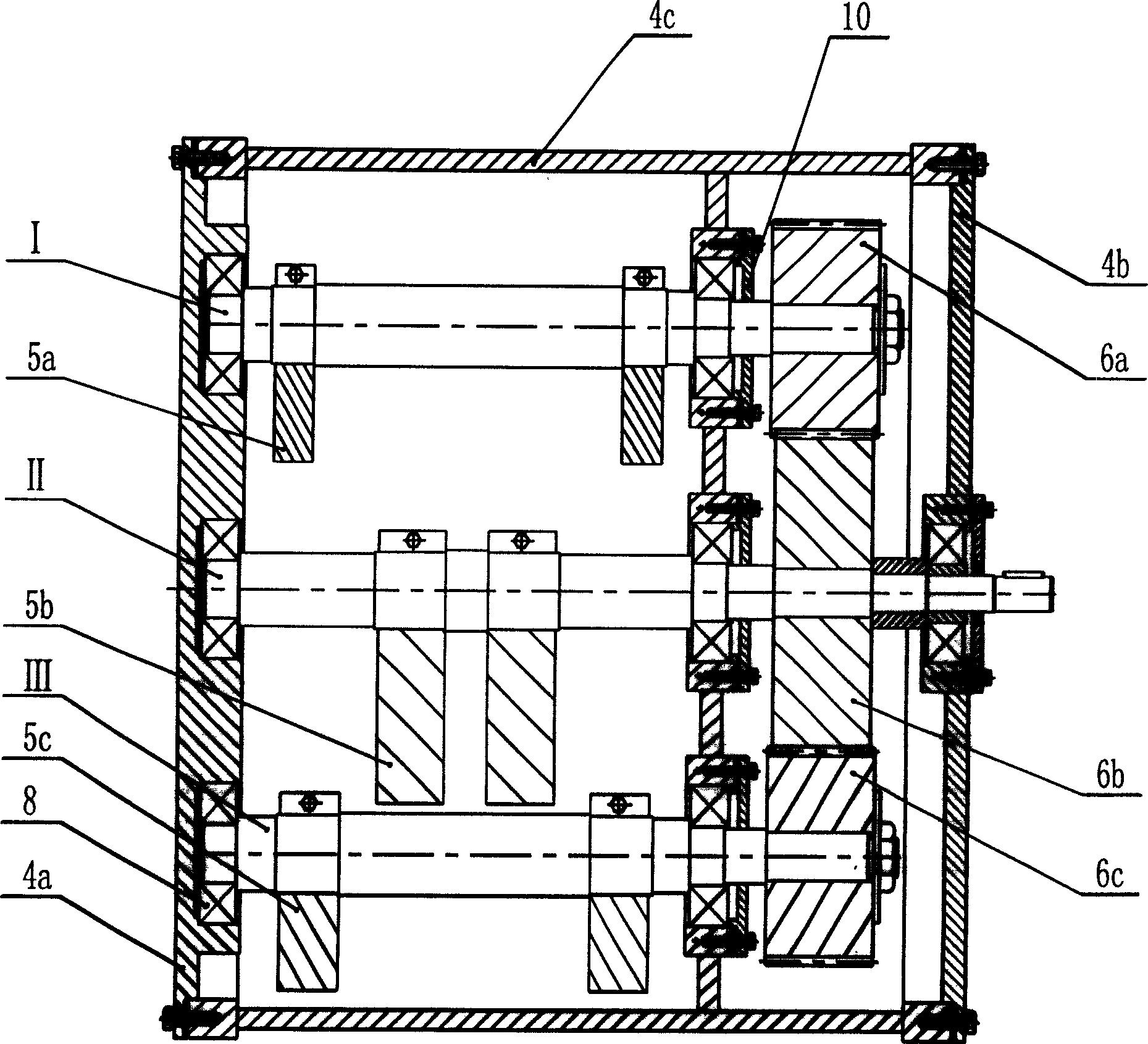

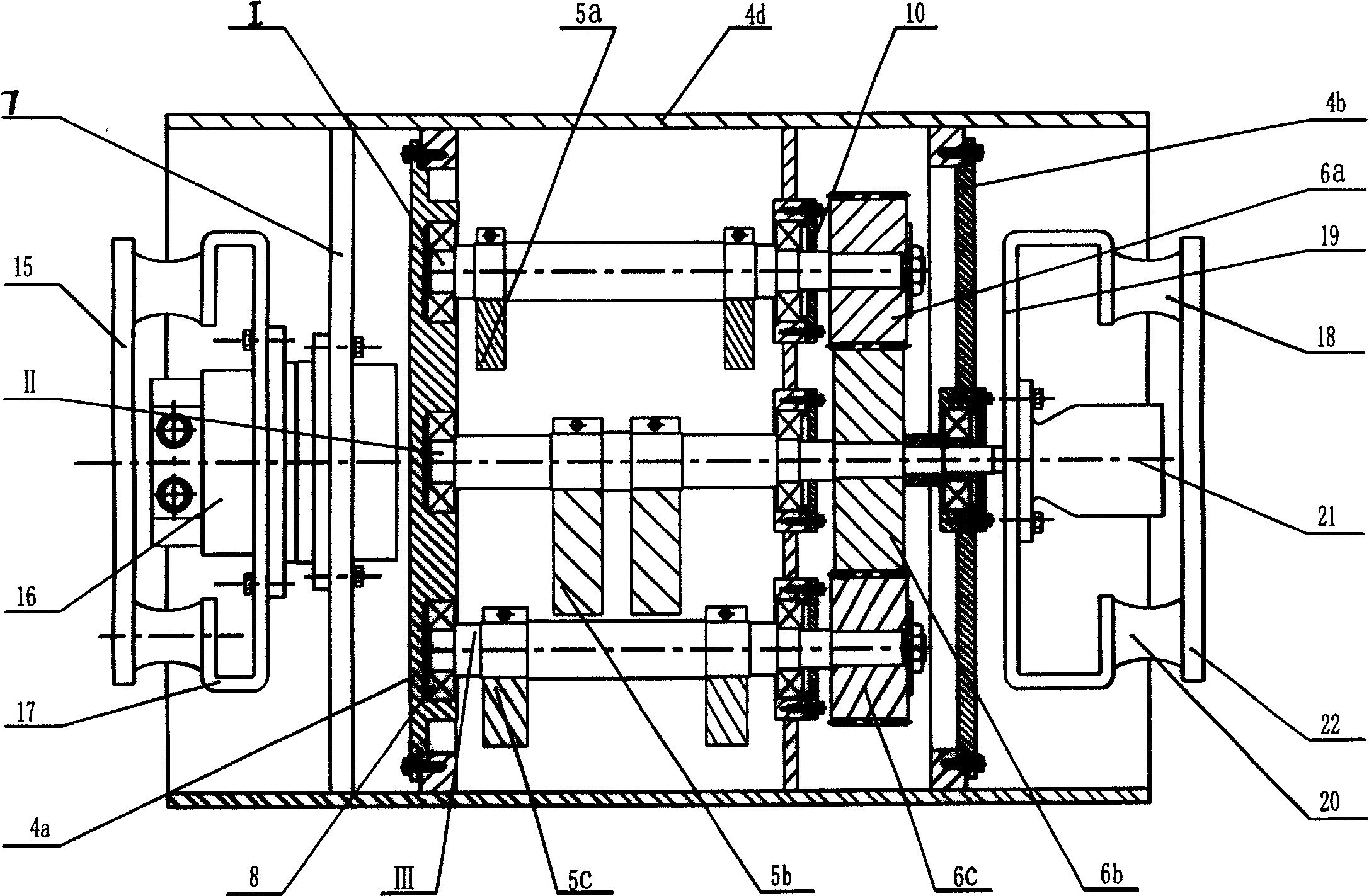

[0011] Refer to the accompanying drawings, Figure 1- figure 2 All shown are three-frequency synthesis exciters, which have a hollow box 4, and three eccentric shafts I, II, and III with different eccentricities are arranged in parallel in the box 4 of the exciter, and the two ends of the eccentric shaft pass through the bearings. 8 is installed on the box body, and the three eccentric shafts I, II, III are sequentially connected by three gears 6a, 6b, 6c with unequal diameters, and the shaft rod of one eccentric shaft II is connected to the external power output through the transmission mechanism Shaft transmission connection, when the exciter is working, the rotation speeds of the eccentric shafts I, II and III are different.

[0012] exist figure 2 In the shown device, the box 4 of the exciter is composed of a left end cover 4a, a housing 4c and a right end cover 4d, and the three eccentric shafts I, II, III are installed on the box through bearings 8 respectively, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com