Large-sized air-cooled fan blade wity synergistic antivibration action

A cooling fan and blade technology, which is applied to the components of the pumping device for elastic fluid, mechanical equipment, machine/engine, etc., can solve the fatigue damage, the disadvantage of large-scale air cooling fan efficiency and operation reliability, and the reduction of fan operation efficiency. and other problems to achieve the effect of reducing vibration, reducing efficiency loss and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

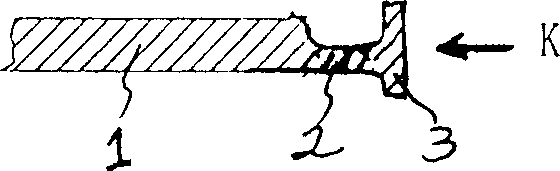

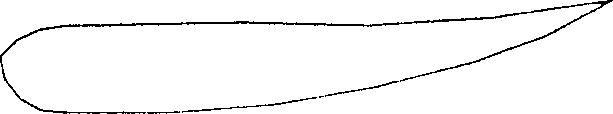

[0012] A large-scale air-cooled fan blade with synergistic and anti-vibration effects, including a blade 1, an airfoil section 2 with a relatively tapered thickness is arranged at the tip of the blade 1, and the outer side of the airfoil section 2 with a tapered thickness is connected with a vertically arranged choke plate 3. The spoiler 3 is integrated with the airfoil section 2 with tapered tip thickness, and the upper and lower ends of the spoiler 3 are respectively located above and below the airfoil section 2 with tapered tip thickness, that is, the spoiler 3 The airfoil section 2 with tapered thickness of the blade tip is connected in a " " shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com