Tin-plated board corrosion-resistance rapid detecting method

A detection method and technology of tinplate, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring device, instrument, etc., can solve the problems of numerous detection procedures, high detection operation requirements, limitation of tinplate reference function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The YQ-Z-48A whiteness and color measuring instrument produced by Hangzhou Qingtong Instrument Development Co., Ltd. was used to sample the whiteness of the corrosion-resistant alloy layer of the tinplate.

[0020] The specific operation steps are as follows:

[0021] (1) Sampling of tin plate

[0022] Take tinplate production samples on site, and punch three disc samples with a diameter of 25.4 mm in the width direction on the punching machine.

[0023] (2) Detinning treatment

[0024] Clean the tinplate sample with electrochemical method, the cathode is 30 seconds, the anode is 5 seconds, then the cathode is 30 seconds, the anode is 5 seconds, and the cathode is 30 seconds; after cleaning, put 20~50g / L NaOH and 5~10g / L L's KIO 3 The tin layer is removed in the solution formed, and the tin removal time is 10 to 20 minutes. In this embodiment, the NaOH of 50g / L and the KIO of 10g / L are put in after cleaning. 3 The tin layer is removed in the formed solution, and the...

Embodiment 2

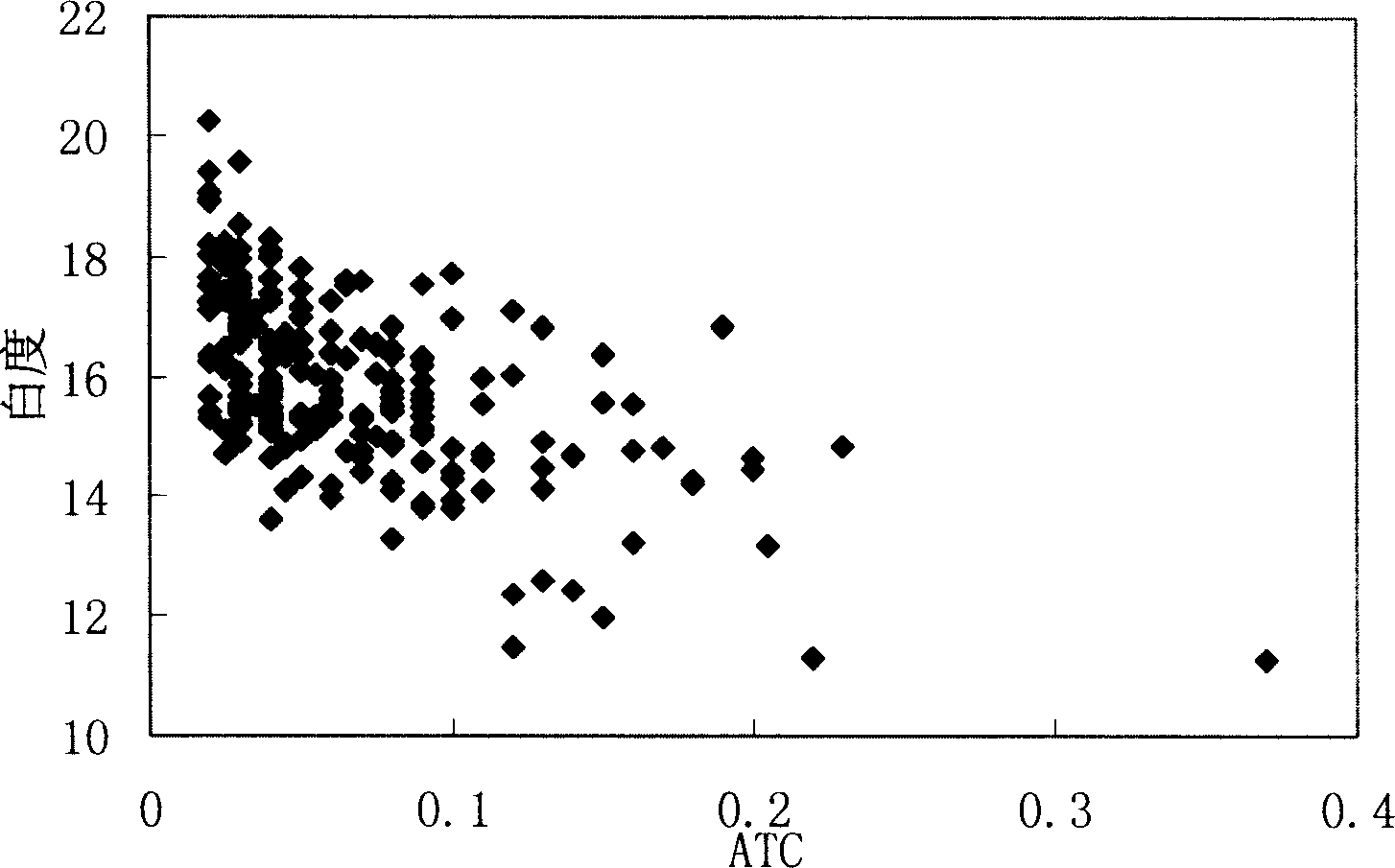

[0031] For the ATC corrosion resistance test and whiteness test of the tinplate in the past three months, the distribution map of the whiteness value and ATC value can be found in figure 1 .

[0032] according to figure 1 The distribution diagram shows that: when the whiteness value of the alloy layer is lower than 12, the ATC values are basically all higher than 0.12μA / cm2, and when the whiteness value of the alloy layer is higher than 16, the ATC values are basically all lower than 0.12μA / cm2, and when the whiteness value of the alloy layer reaches 18, the ATC value of the alloy layer is between 0.02 and 0.04μA / cm2.

[0033] When the whiteness detection value of the alloy layer of the tinplate is ≥16, it is judged that the corrosion resistance of the tinplate is good, and the corresponding ATC range is 0.02-0.12. In order to determine the ATC level of the tinplate, a sample size of 1:10 is used for ATC testing and random inspection ;When the whiteness value is 14-15, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com