Coating material and mirror coated therewith

An edge and coating technology, applied in the direction of epoxy resin coating, application, coating, etc., can solve the problems of poor quick-drying, film whitening, long drying and curing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

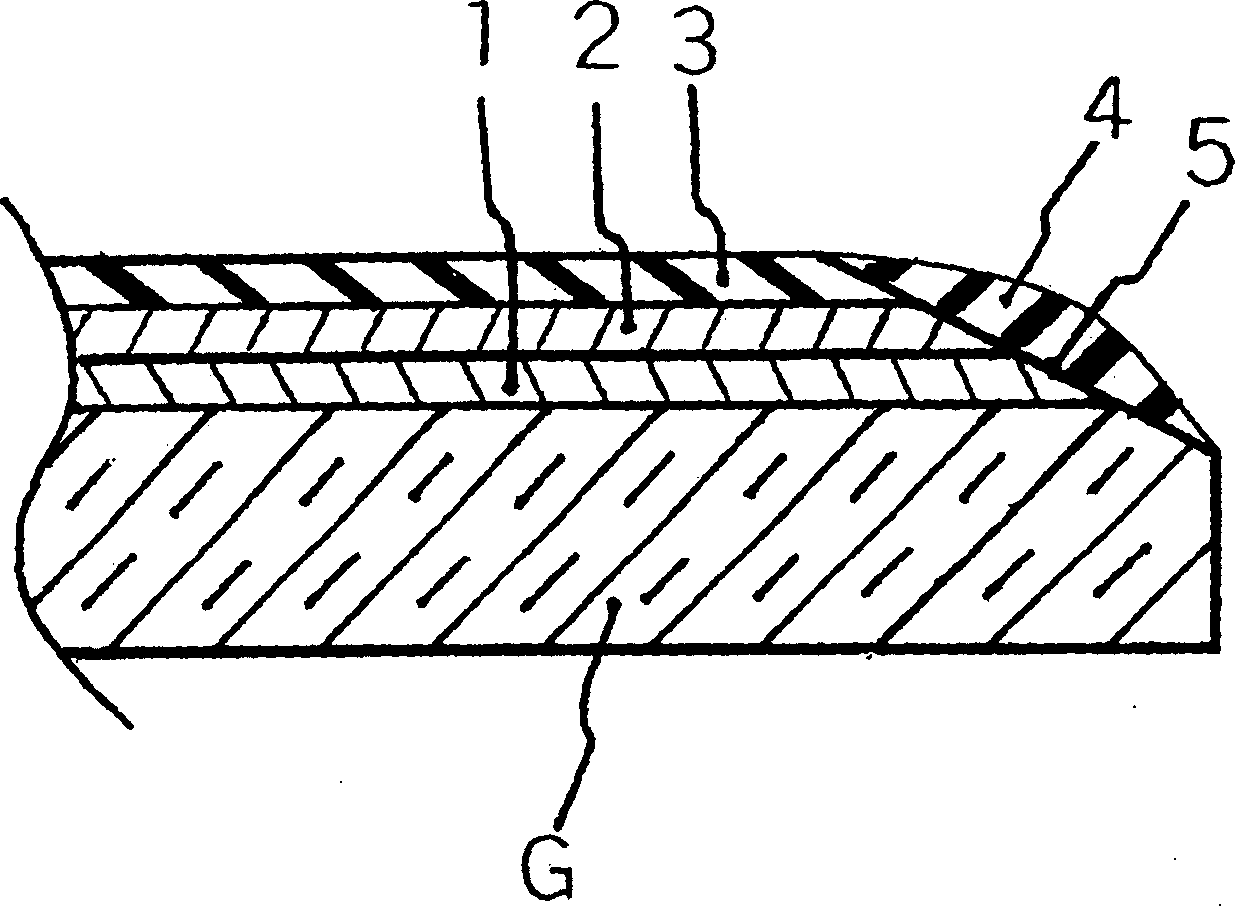

Image

Examples

Embodiment 1

[0085] The water-based mirror coating in Example 1 uses an acrylic silicone resin emulsion (manufactured by Asahi Kasei Chemical Co., Ltd., product name Polyurex G623, non-volatile content is 46.0% by weight, prepared in water) with a TG of 20.0° C. The water-based mirror is prepared with the amount of the total weight of the paint. The water-based mirror coating in Example 2 uses an acrylic silicone resin emulsion with a TG of 50.0° C. (manufactured by Toa Synthetic Chemical Co., Ltd., trade name シ-ラス PC100, the non-volatile content is adjusted to 46.0% by weight), and 70% is added to the water-based coating. The mirror is modulated with the amount of the total weight of the paint. The water-based mirror paint in Example 3 was used in an acrylic silicone resin emulsion (manufactured by Asahi Kasei Chemical Co., Ltd., trade name Polyurex G620, non-volatile content: 46.0% by weight) at a TG of 20.0°C, and 20% silane monolayer was added. (Toray Dow Corning Silicon Co., Ltd., tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com