Ridged wave-guiding high-power semiconductor laser structure with conical gain zone

A technology of tapered gain region and ridge waveguide, which is applied in the field of ridge waveguide high-power semiconductor laser structure, can solve the problems of semiconductor laser maximum output power and beam quality limitation, multiple side modes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

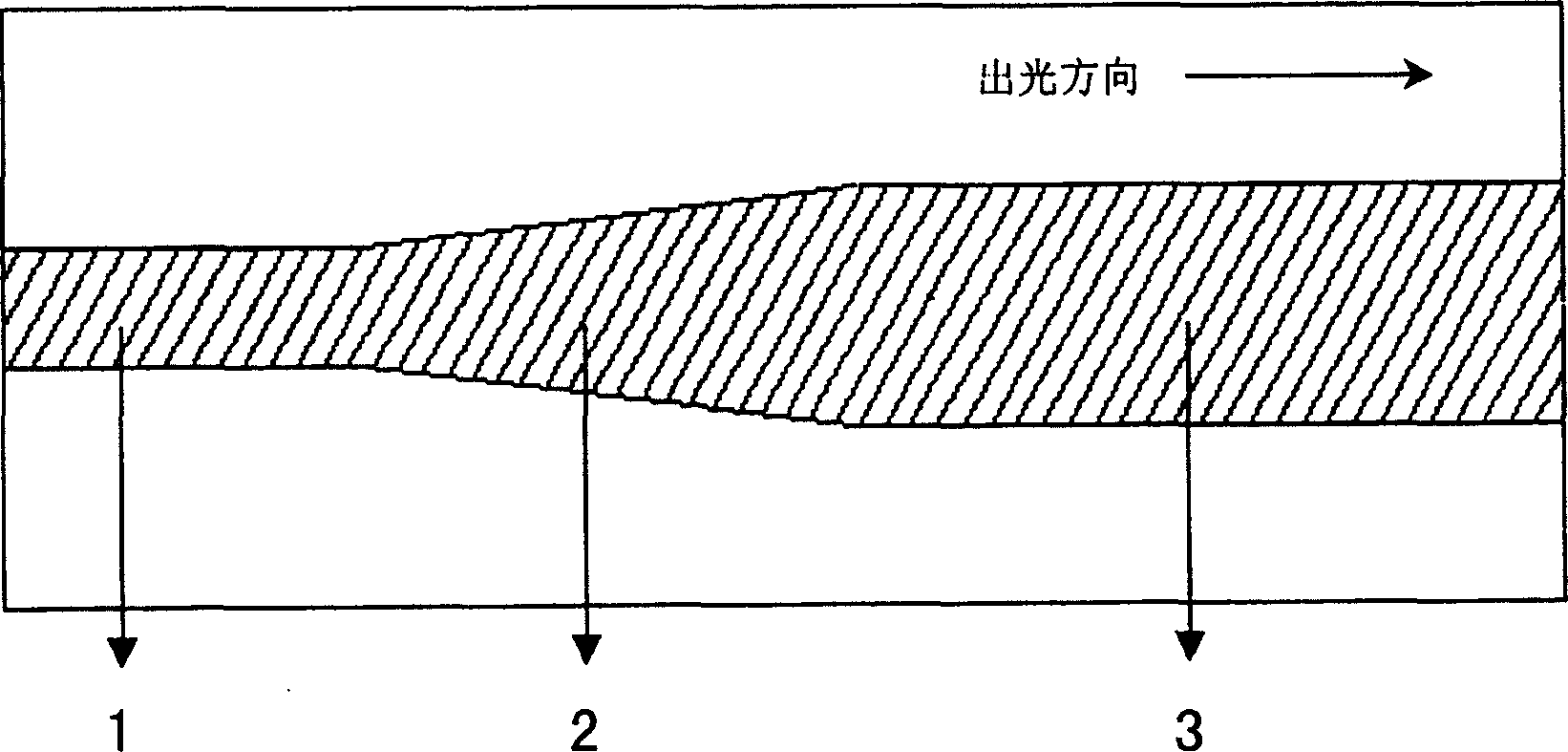

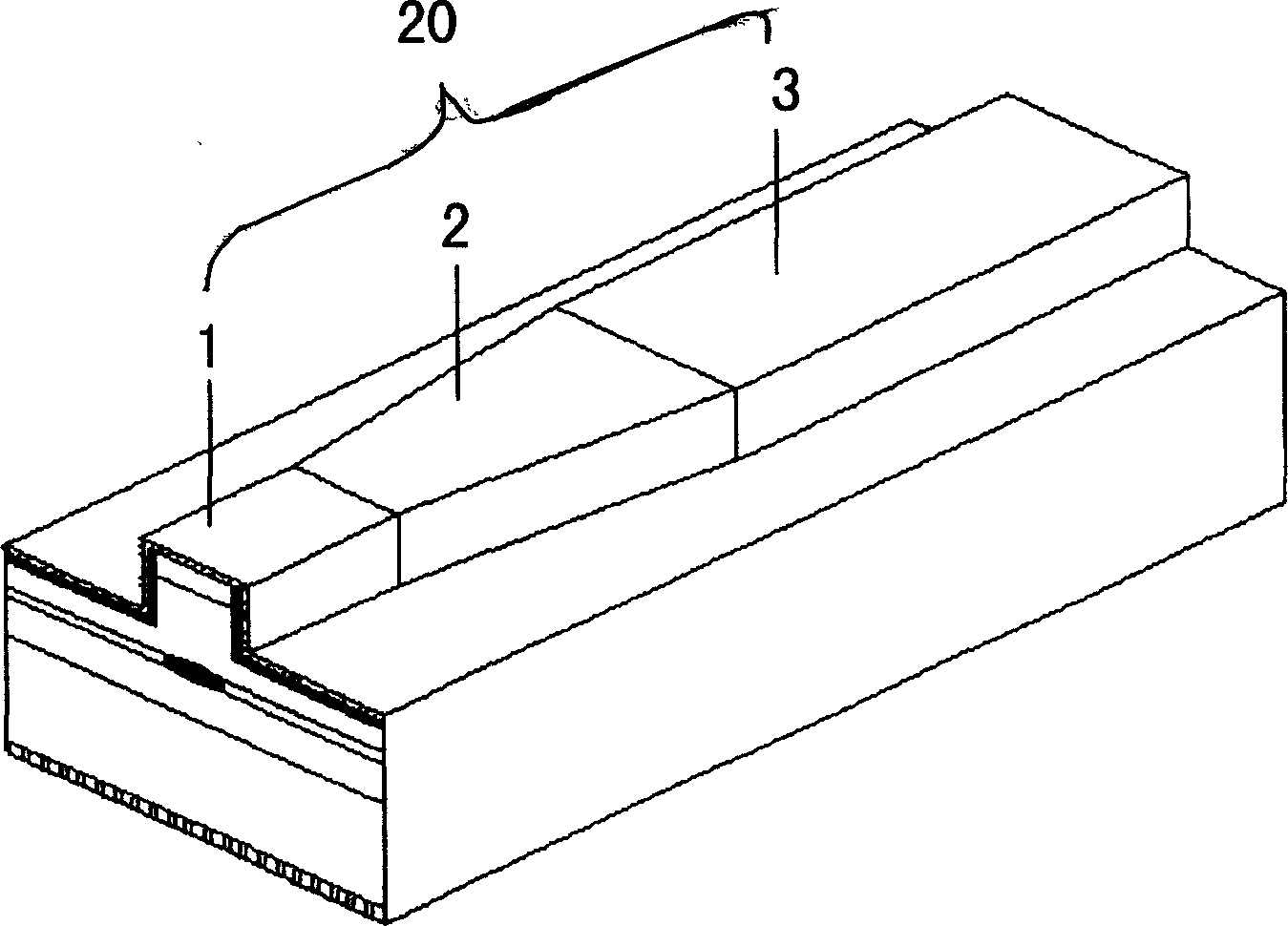

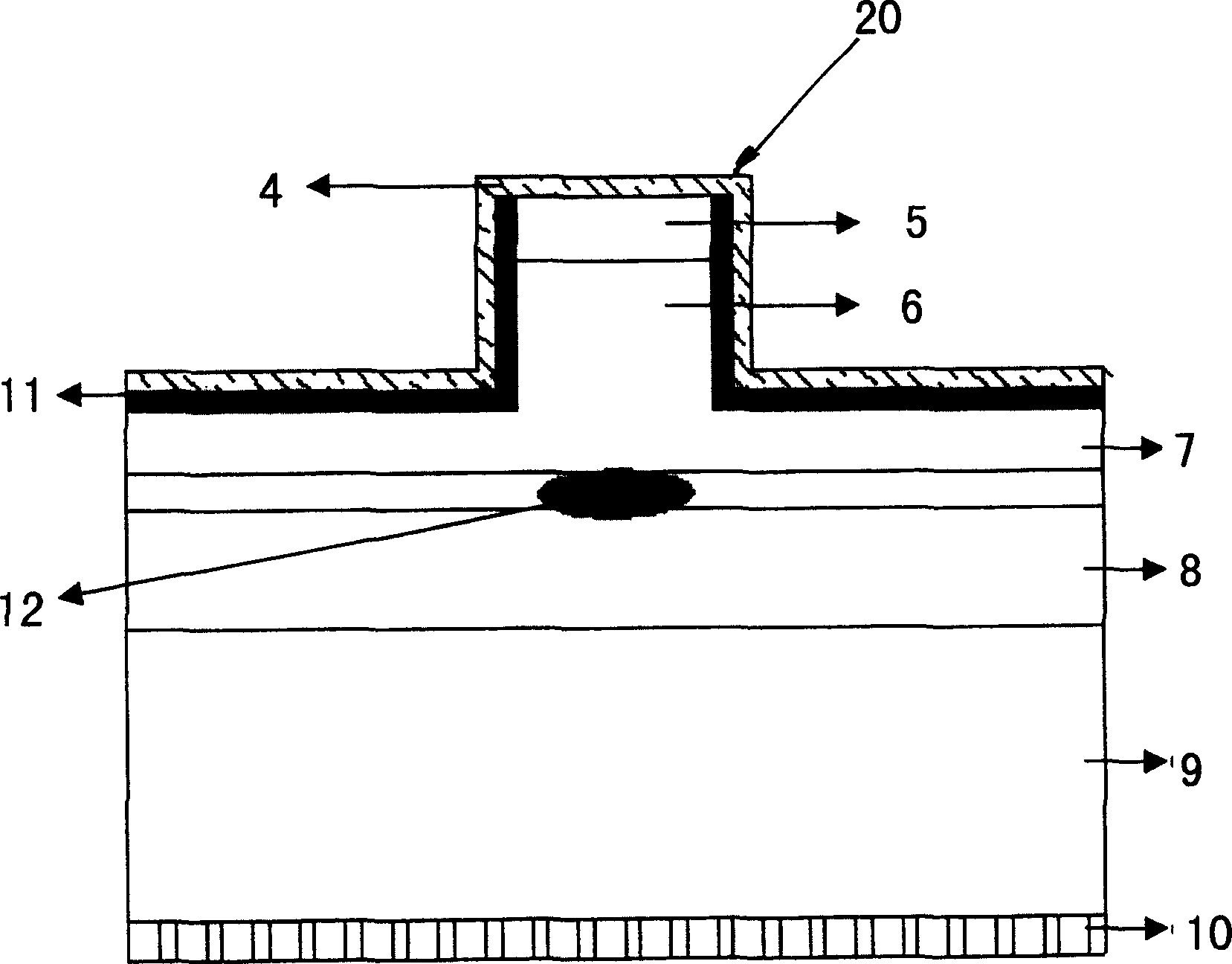

[0030] see figure 1 , figure 2 and image 3 As shown, the present invention has a ridge waveguide high-power semiconductor laser structure with a tapered gain region, which is characterized in that it includes:

[0031] a substrate 9, the substrate 9 is an indium phosphorus material;

[0032] An AlGaAs layer 8, the AlGaAs layer 8 is fabricated on the substrate 9, and the AlGaAs layer 8 is N-type doped;

[0033] An AlGaInAs active layer 12, the AlGaInAs AlGaInAs active layer 12 is fabricated on the AlGaAs 8, the AlGaInAs active layer 12 is a respectively constrained strained quantum well structure, lasing The wavelength is 14xxnm;

[0034] An AlInAs layer 7, the AlInAsAlInAs layer 7 is fabricated on the AlGaInAs active layer 12, and the AlInAs layer 7 is P-type doped;

[0035] An indium phosphorus layer 6, the indium phosphorus layer 6 is fabricated on the aluminum indium arsenic layer 7, the area of the indium phosphorus layer 6 is smaller than the area of the alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com