Purifying system and method

A technology for accommodating tubes and covering bodies, applied in the field of purification systems, can solve the problems of deterioration, low yield of purified products, inability to reduce costs and purification procedures and time, and achieve the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

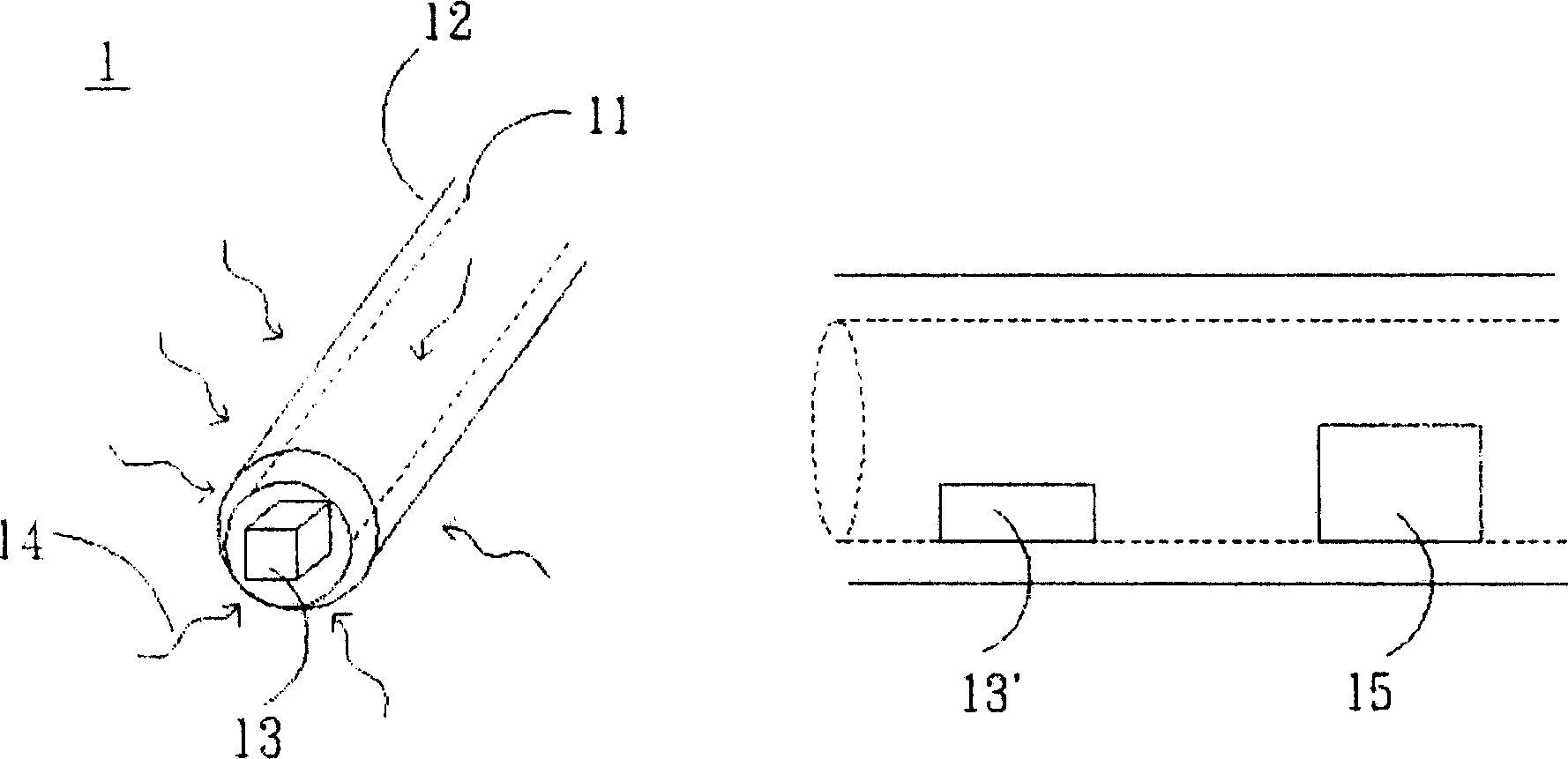

[0015] The purification system and purification method according to preferred embodiments of the present invention will be described below with reference to the relevant drawings, wherein the same components will be described with the same reference numerals.

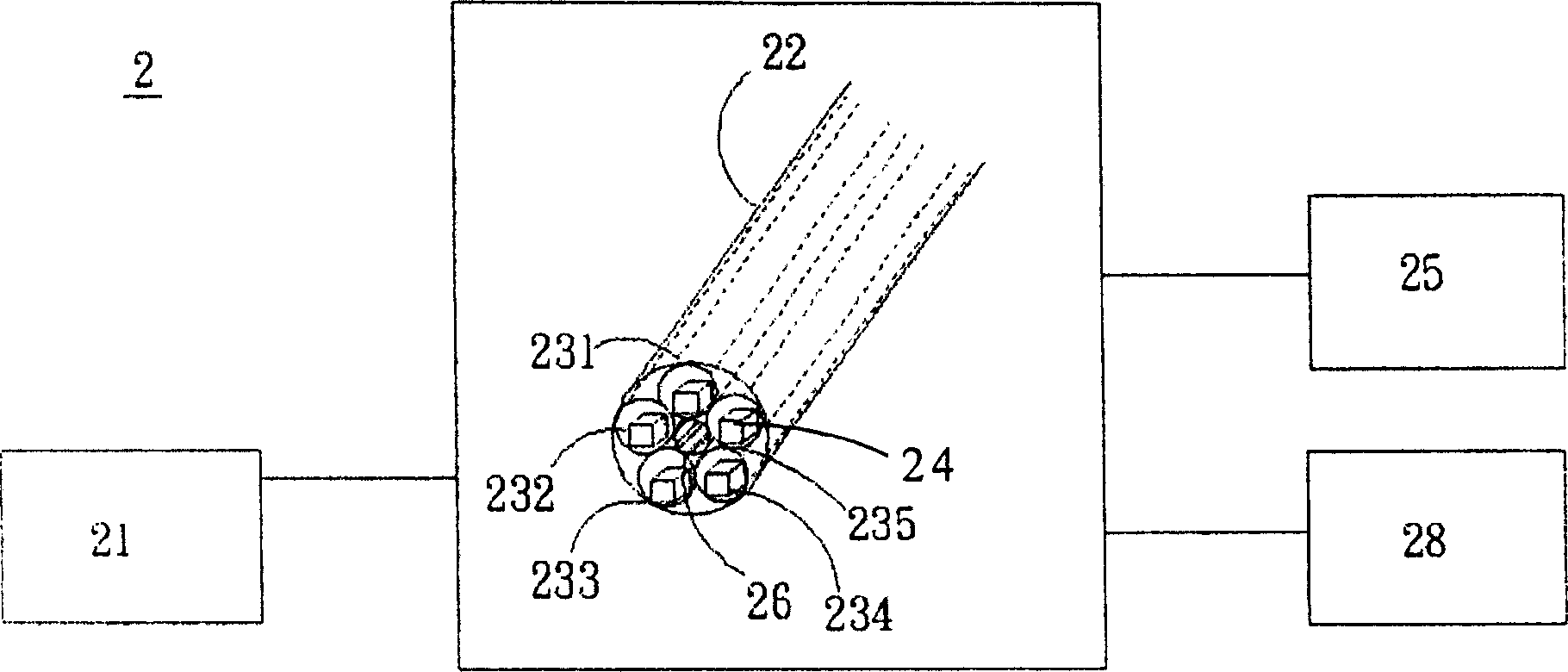

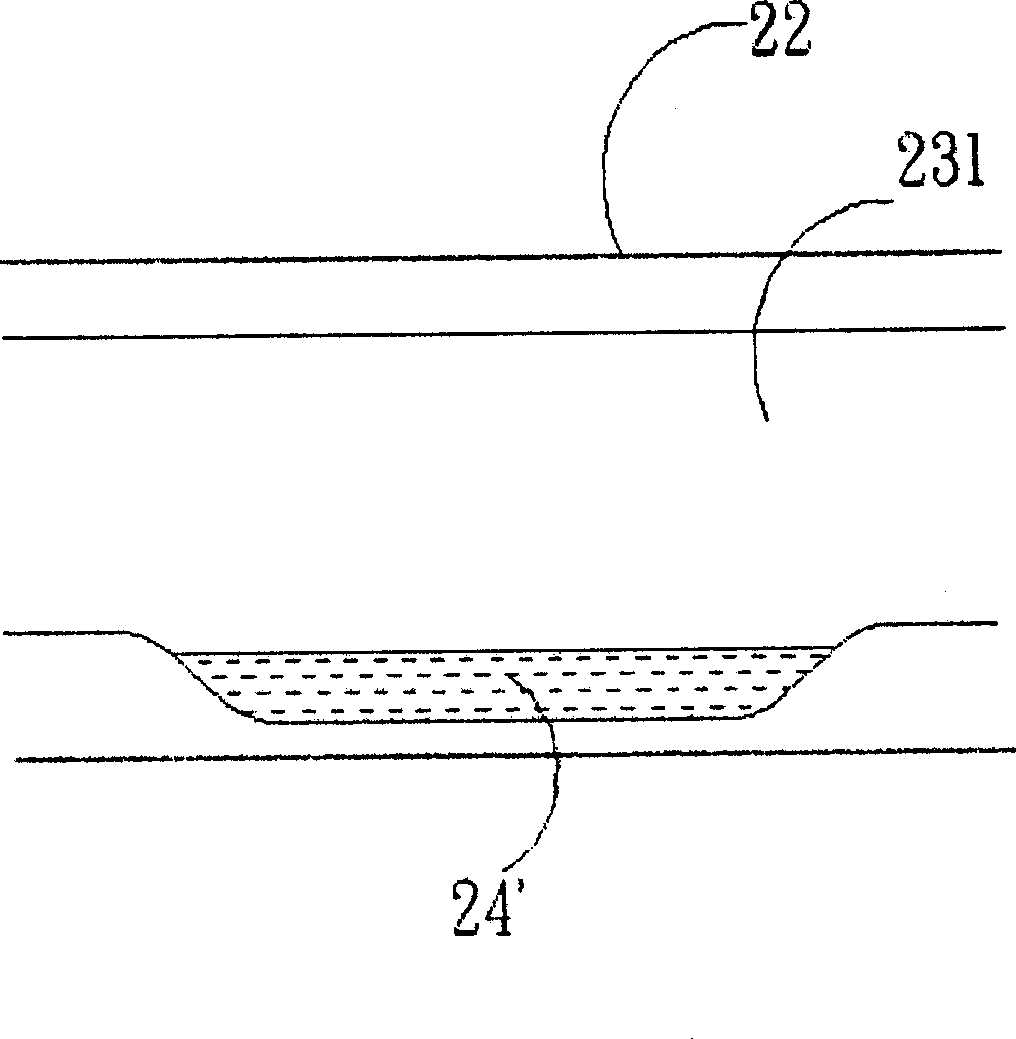

[0016] see figure 2 , which is a schematic diagram of a purification system according to a preferred embodiment of the present invention. In this embodiment, the purification system 2 includes an input device 21 , a cladding body 22 , containing tubes 231 to 235 , a high temperature furnace 25 , a heater 26 and an output device 28 . Wherein, the input device 21 is used to input at least one object to be purified 24 to at least any one of the holding tubes 231 to 235, and each object to be purified 24 can be solid and liquid organic materials with different sublimation points to be purified. , or more than one other substances to be purified with similar sublimation points can be input into the holding tubes 231 to 235...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com