Spinning method

A technology of spinning and thread, which is applied in rayon manufacturing, filament/thread forming, textile and paper making, etc. It can solve the problems of complex operation, limited thread fineness, poor continuity, etc., and achieve simple equipment, improved product performance, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

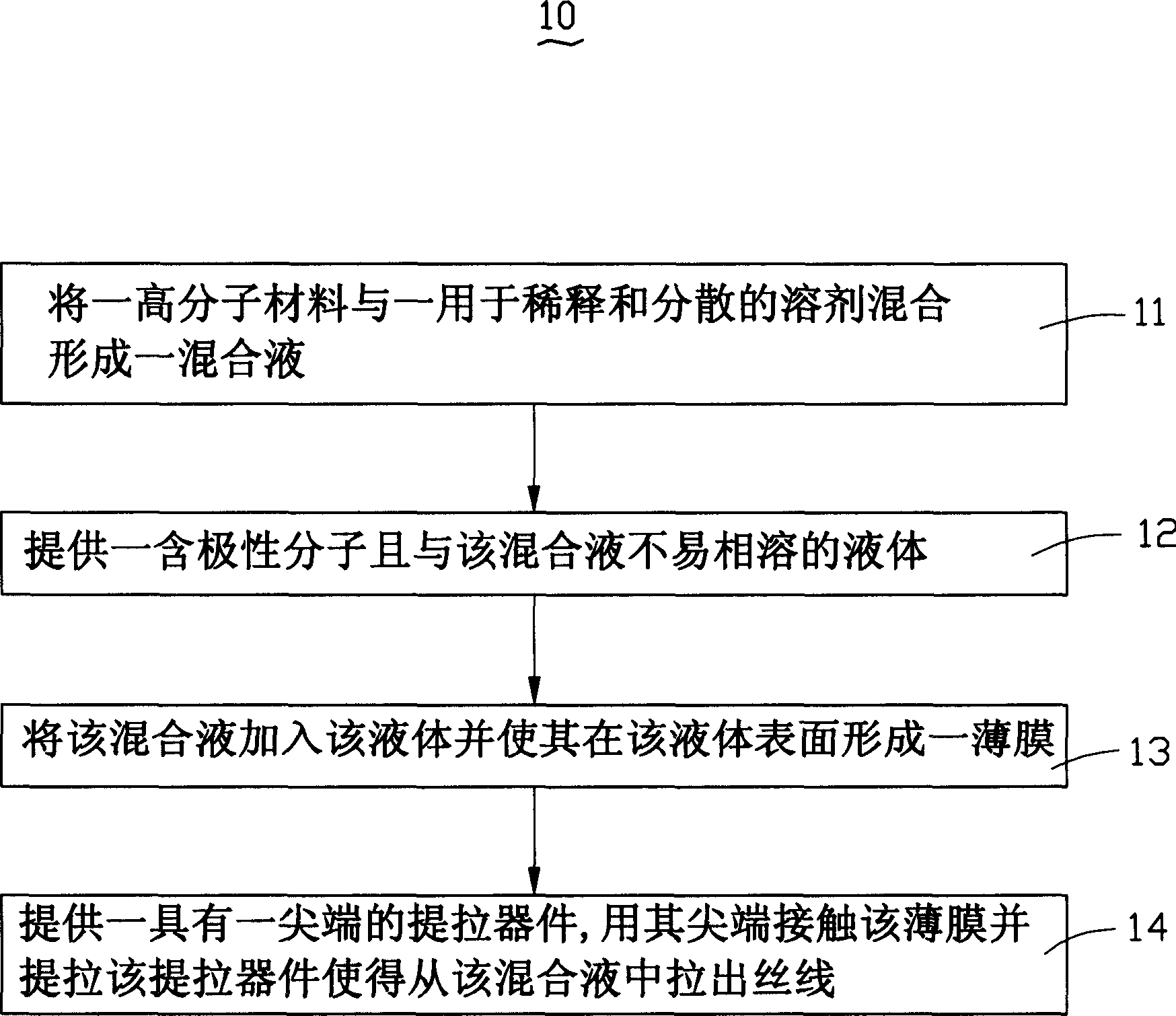

Method used

Image

Examples

Embodiment 1

[0032] Add 6 drops (about 0.2 ml) of polyurethane glue (101 glue) to a beaker filled with 20 ml of ethyl acetate, and then add 2 mg of carbon nanotubes to form a mixed solution. The beaker containing the mixture was ultrasonically dispersed in a KQ-500B ultrasonic cleaner for 5 minutes. Then immediately extract the mixed solution with a syringe for injection, and drop 6-10 drops (about 0.2-0.3 ml) of the mixed solution into deionized water packed in a stainless steel plate, and the water temperature is about 30 degrees Celsius. After about 20 to 30 seconds, use a medical needle dipped in the liquid surface to pull out the silk, and wrap it around the plastic shaft driven by the stepping motor. The stepping motor rotates to drive the drawing, about 12cm / sec. The diameter of the filaments is about 1 micron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com