Color filter panel, display apparatus having the same, and method of manufacturing the same

A color filter, color filter technology, applied in optics, optical elements, nonlinear optics, etc., can solve problems such as reducing the productivity of semi-reflective display devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following embodiments of the present invention will be described in detail with reference to the accompanying drawings.

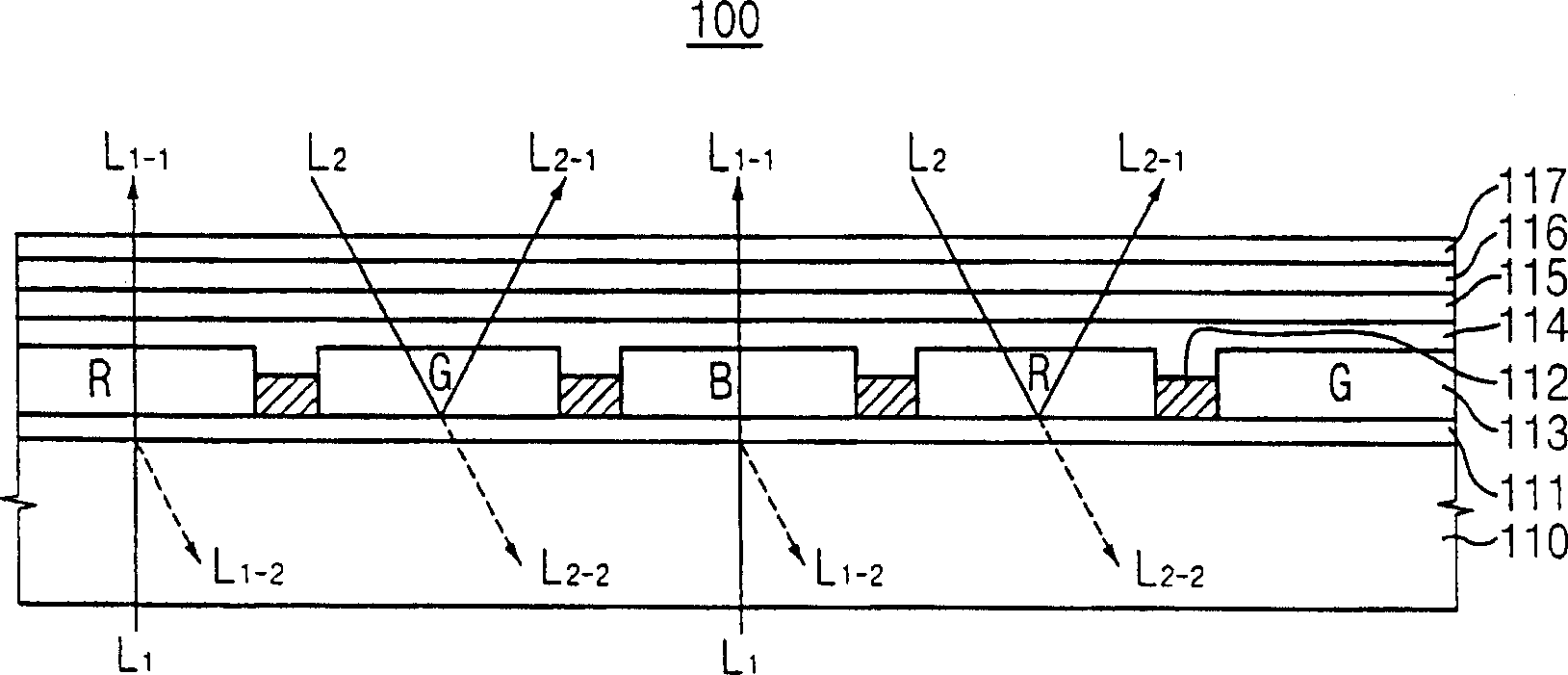

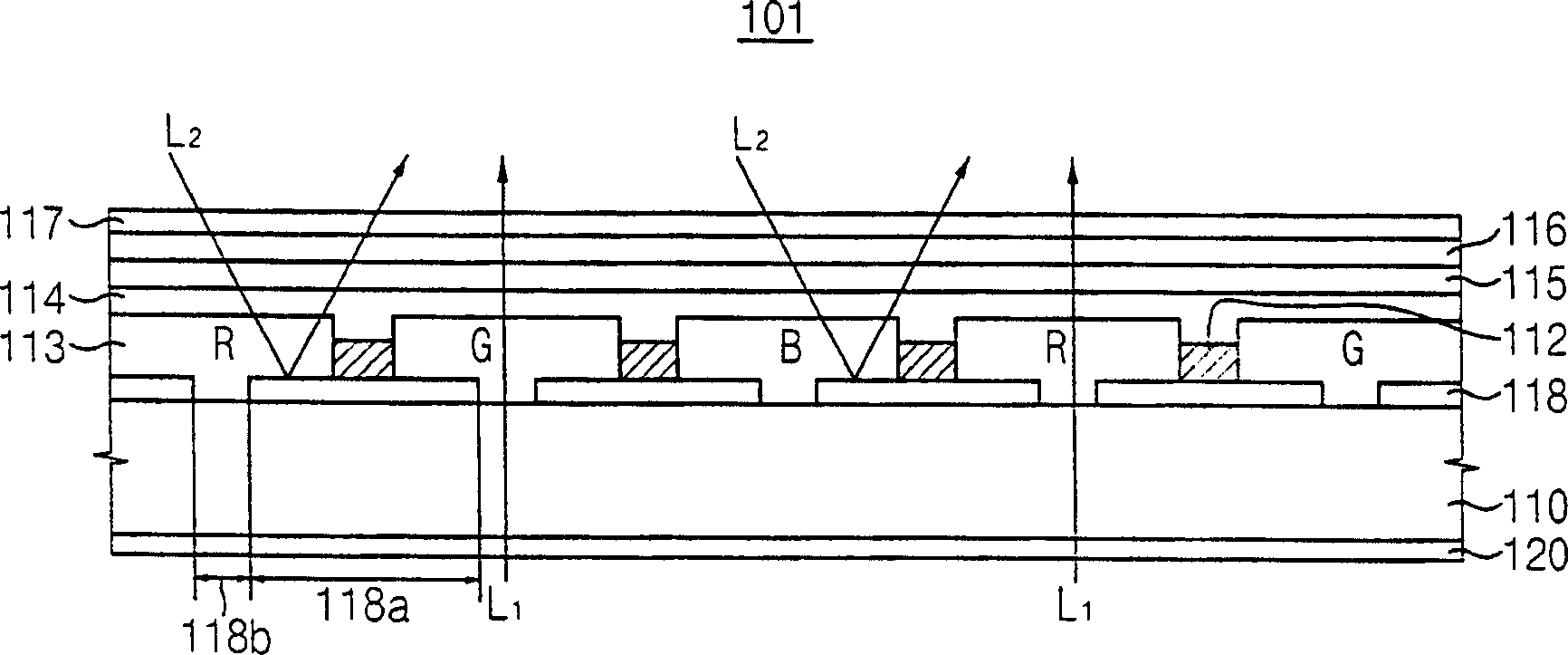

[0038] figure 1 is a sectional view of the color filter panel according to the first embodiment of the present invention. refer to figure 1 , the color filter panel 100 is combined with a switch panel (not shown) to form a display panel (not shown). The color filter panel 100 is adjacent to an internal light generating part (not shown) that generates the first light L1 directed to the first substrate 110 of the color filter panel 100 . Alternatively, a lower polarizer (not shown) may be disposed on the lower surface of the first substrate 110 .

[0039] The color filter panel 100 includes a first substrate 110 , a light reflective element 111 disposed on the first substrate 110 , and a light polarizing layer 115 disposed on the light reflective element 111 . The first light blocking layer 112 and the color filter layer 113 are interposed betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com