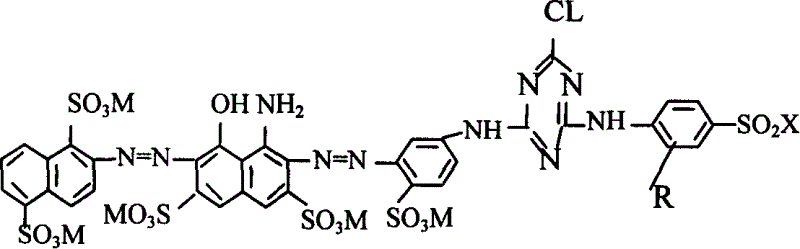

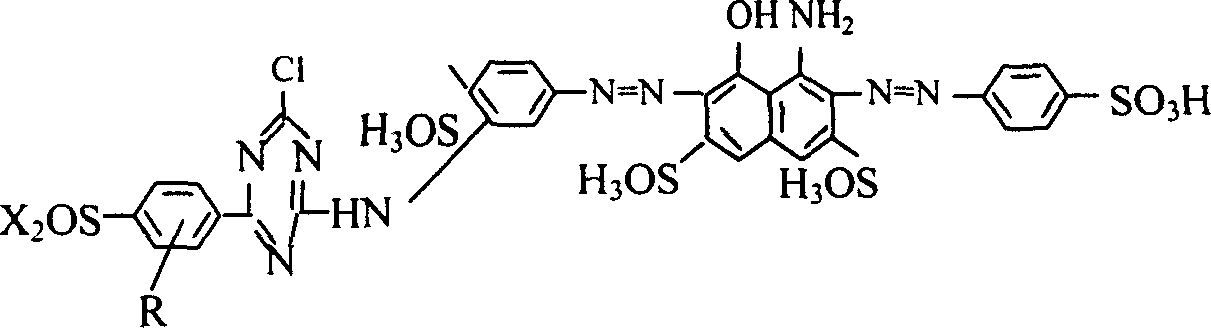

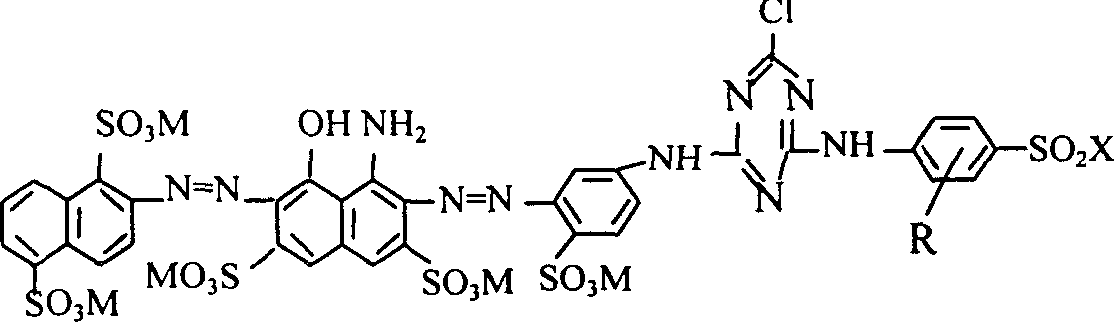

SGL-BR of blue active azo dye and preparation thereof

A technology of SGL-BR and azo dyes, used in azo dyes, reactive dyes, organic dyes, etc., which can solve the problems of poor lifting power, poor dye solubility, and inability to dye dark colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment one: take by weighing 18.5 parts of cyanuric chloride and condense with 28.1 parts of p-(β-hydroxyethylsulfone sulfate) aniline and 21.1 parts of m-bis respectively, and condense the diazonium salt of the condensate with 35.8 parts of H acid Coupled with 29.7 parts of 1.5 acid diazonium salt alkali, membrane treatment and spray drying to get a green light blue dye.

Embodiment 2

[0034] Embodiment two: take by weighing 18.5 parts of cyanuric chloride and carry out condensation with 21.1 parts of metabis and 28.1 parts of p-(β-hydroxyethyl sulfone sulfate) aniline respectively, and the diazonium salt of the condensate and 35.8 parts of H acid Coupled with 29.7 parts of 1.5 acid diazonium salt alkali, membrane treatment and spray drying to get a red light blue dye.

Embodiment 3

[0035] Embodiment three: take by weighing 18.5 parts of cyanuric chloride and condense with 36.1 parts of p-(β-hydroxyethyl sulfone sulfate) aniline o-sulfonic acid and 21.1 parts of meta-bis respectively, and condense the diazonium salt of the condensate with 35.8 parts H acid acid couple and 29.7 parts of 1.5 acid diazonium salt base couple, film treatment and spray drying make a kind of blue dye that is greener than Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com