Engineering implementation method for quick starting inertial measurement unit of optical fiber gyroscope and guaranteeing precision

A fiber-optic gyroscope and fast-start technology, applied in Sagnac effect gyroscopes and other directions, can solve the problems of large output noise of fiber-optic gyroscopes, limit the application of fiber-optic gyroscopes, and difficult to achieve fast start-up, and reduce zero temperature drift and Noise, alleviating the contradiction between accuracy and cost, and the effect of reducing accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

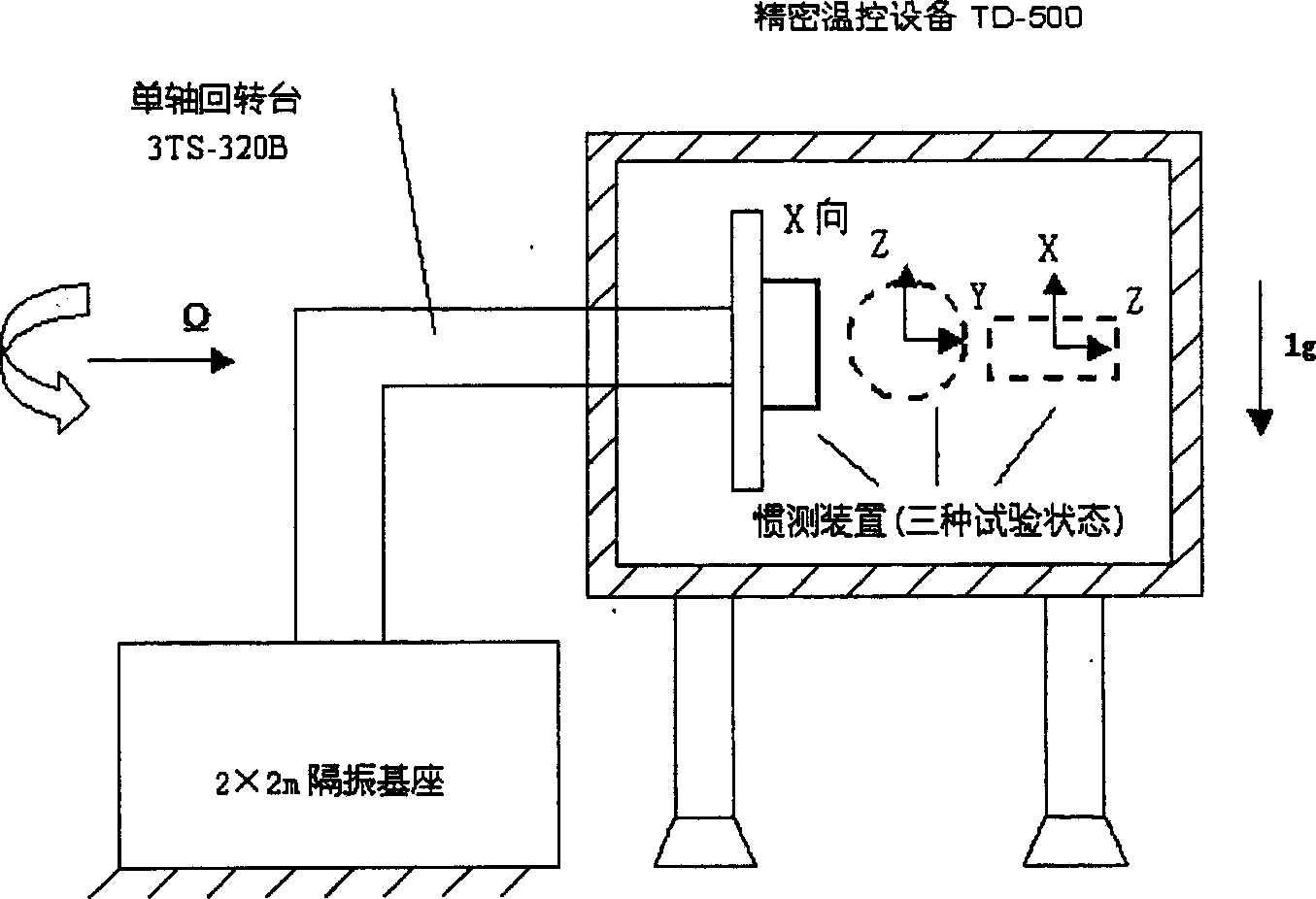

[0020] Such as figure 1 As shown, the calibration test equipment of the present invention is composed of a high-precision temperature control device TD-500 and a single-axis precision rotary table 3TS-320B. Perform temperature control. Because the turntable is installed on the vibration-isolation base, the working vibration of the temperature control equipment and the movement of personnel will not affect the IMU, ensuring the reliability of the test data.

[0021] The IMU is installed on the mounting surface of the turntable, and the input axis of the tested angular rate is horizontal. The rotary table works in the rate mode, which can calibrate the rate of the gyroscope. In the position mode, the rotary table is set to work as a digital grating dividing head, and the linearity test of the accelerometer within the range of ±1g is performed. Calibrate the IMU at the set temperature point to obtain the zero bias of the instrument.

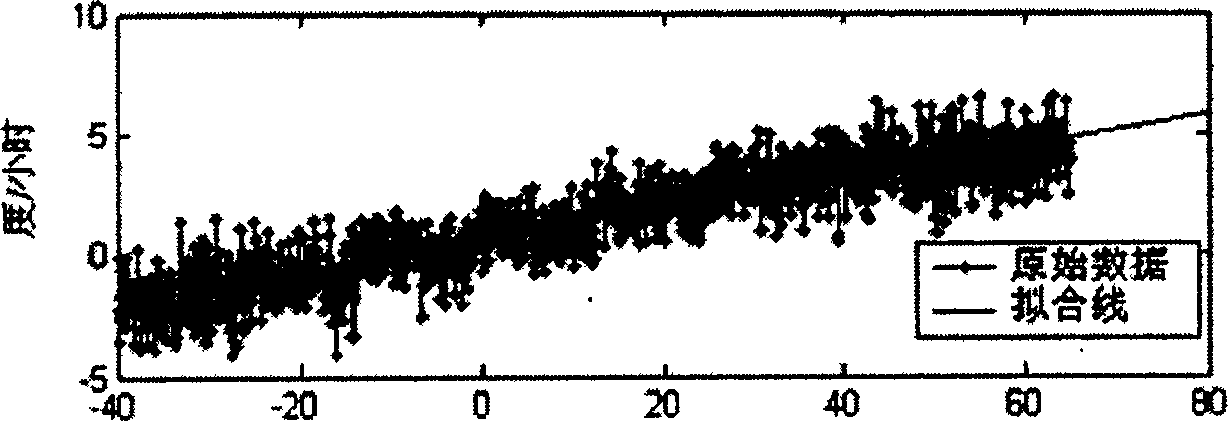

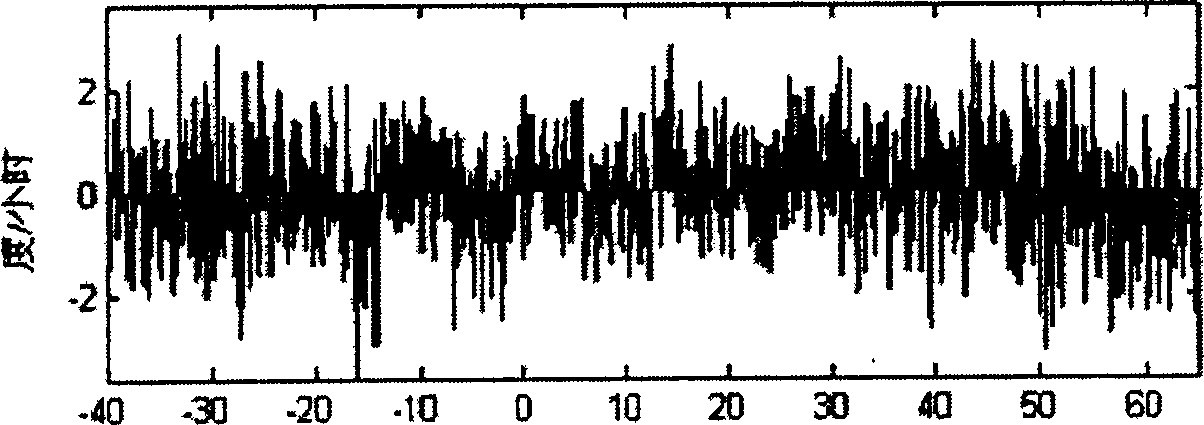

[0022] Using the above-mentioned temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com