Aramid fiber reinforced core for optical cable

A fiber optic cable strengthening core and aramid fiber technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of slow production rate, poor bonding of surface sheath materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

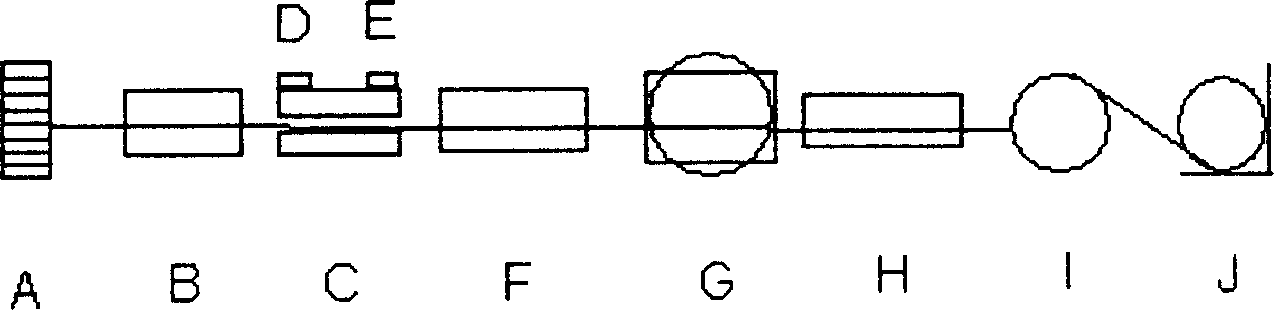

[0029] Such as image 3 As shown, pull out the aramid yarn from the creel (A), try to avoid fiber bruising and fiber fluffing, and to prevent the aramid yarn from being twisted together, thread the aramid yarn in a regular and orderly manner. The aramid yarn should be evenly distributed on the splitting roller. Pass each bundle of aramid yarn passing through the splitting roller through the mold (B), and there should be no phenomenon of broken ends not passing through.

[0030] To prepare resin raw materials, it should be fully stirred on the mixer, and the stirring time should not be less than 5 minutes. The stirred resin raw materials must be filtered through an 80-mesh sieve before being poured into the resin tank (C).

[0031] Set the temperatures of the curing area (D) and the shaping area (E) of the mold to 200±10°C and 140±10°C respectively, and heat the mold with electricity.

[0032] The aramid yarn is heated by the resin tank and the heating mold, and then shaped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com