Separated coating film and its preparation process

A manufacturing method and coating film technology, applied in the direction of coating, etc., can solve the problems of not being able to use fast packaging machines, high consumption of paint, and large wood consumption, and achieve dust absorption, low adsorption, and excellent material properties price ratio effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The raw materials used are: dimethylsiloxane organic silicon paint, which is purchased from the market and has a solid content of 30%.

[0031] Platinum Catalyst: Available from the market.

[0032] Single silicon anchoring agent: available from the market.

[0033] Dimethicone bridging agent: available from the market.

[0034] Biaxially oriented polypropylene film with a thickness of 48 μm.

[0035] Weigh 42 kilograms of toluene into a stainless steel container, add 12 kilograms of silicone paint, slowly stir to dissolve it in toluene, then add 75 grams of bridging agent, 35 grams of catalyst and 35 grams of anchoring agent in turn while stirring, After stirring evenly, it will be used in the next process.

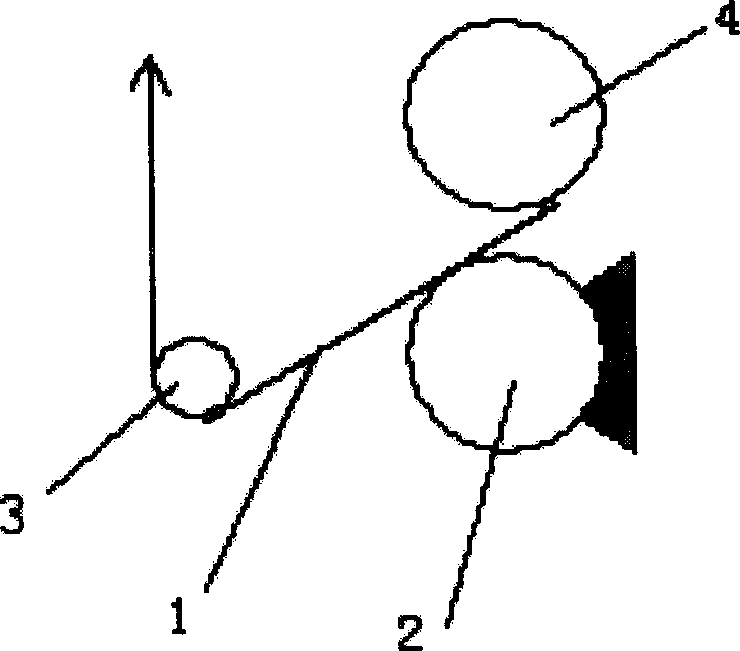

[0036] The biaxially oriented propylene film is corona treated after unwinding, such as figure 1 As shown, by the reverse roll kiss coating method, the coating roll 2 is used to uniformly transfer the release coating to the film 1 to prevent the coating from c...

Embodiment 2

[0038] The raw materials used are: dimethylsiloxane organosilicon coating, which is purchased from the market and has a solid content of 20%.

[0039] Platinum Catalyst: Available from the market.

[0040] Single silicon anchoring agent: available from the market.

[0041] Dimethicone bridging agent: available from the market.

[0042] The polyester film thickness is 240 μm.

[0043] Weigh 20 kg of No. 120 gasoline into a stainless steel container, add 43 kg of silicone paint, slowly stir to dissolve it in toluene, then add 65 g of bridging agent, 25 g of catalyst and 25 g of anchoring agent in turn while stirring , stir evenly and wait for the next process to use.

[0044] The polyester film substrate film is corona treated after unwinding, such as figure 1 As shown, the release coating was uniformly transferred to the film 1 with the coating roll 2 by the reverse roll kiss coating method, and the coating weight was 0.6 g / m 2 . After drying with far infrared rays and ho...

Embodiment 3

[0046] The raw materials used are: dimethylsiloxane organic silicon paint, which is purchased from the market and has a solid content of 40%.

[0047] Platinum Catalyst: Available from the market.

[0048] Single silicon anchoring agent: available from the market.

[0049] Dimethicone bridging agent: available from the market.

[0050] The thickness of the biaxially oriented polypropylene film was 12 μm.

[0051] Weigh 40 kilograms of heptane in a stainless steel container, add 6 kilograms of silicone paint, slowly stir to dissolve it in toluene, and then add 300 grams of bridging agent, 50 grams of catalyst and 50 grams of anchoring agent in turn while stirring, After stirring evenly, it will be used in the next process.

[0052] After unwinding, the biaxially oriented polypropylene film 1 is subjected to corona treatment, and the release coating is uniformly transferred to the biaxially oriented polypropylene film by a conventional roll coating method with a coating rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com